Functional characteristics

TIG welding

76 Item No.: 099-004833-EWM01

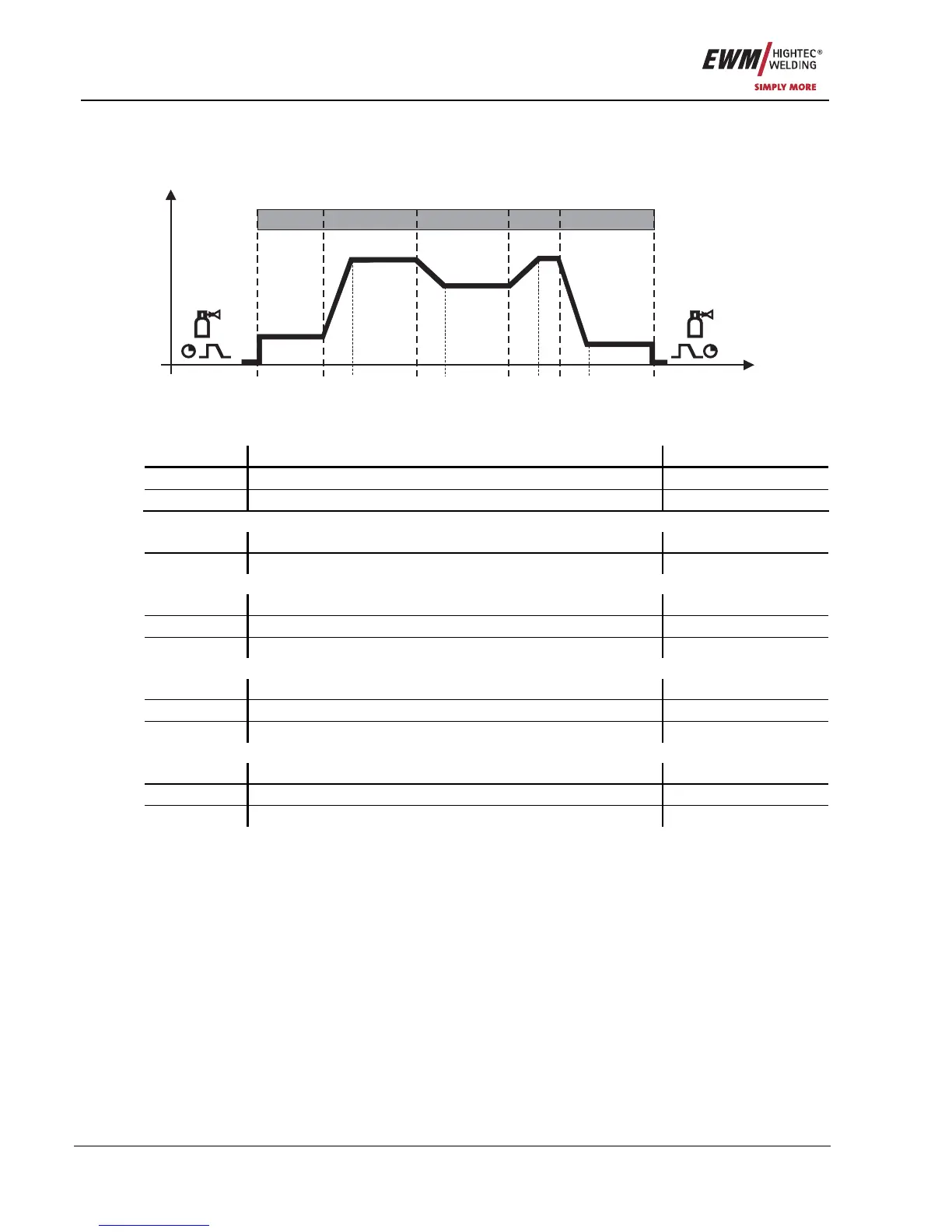

5.3.7 TIG program sequence ("Program steps" mode)

5.3.7.1 TIG parameter overview

The parameter settings are made on welding machine control M3.10 or M3.11

Istart

I3

Iend

tstart tS1 t2 tS2 t3 tS3 tSe tend

P

START

P

A

P

A

P

B

P

END

t

I

Figure 5-36

Basic parameters

Display Meaning / explanation Setting range

GASstr Gas pre-flow time 0.0s to 0.9s

GASend: Gas post-flow time 0.0s to 20s

"P

START

" start program

Istart Ignition current 0% to 200%

tstart Duration 0.0s to 20s

"P

A

" main program

tS1 Slope duration from P

START

to P

A

(Upslope) 0.0s to 20s

t2 Duration 0.01s to 20.0s

tS3 Slope duration from P

B

to P

A

0.00s to 20.0s

"P

B

" reduced main program

tS2 Slope duration from P

A

to P

B

0.00s to 20.0s

I3 Welding current 0% to 100%

t3 Duration 0.01s to 20.0s

"P

END

" end program

tSe Slope duration from P

A

or P

B

to P

END

(Downslope) 0.0s to 20s

Iend Welding current 0% to 100%

tend Duration 0.0s to 20s

P

START

, P

B

, and P

END

are "relative programs", i.e. they relate to percentages of the welding current setting

(see chap. 3.14)

Various functional sequences can be set up according to the operating mode.

Loading...

Loading...