Functional characteristics

MIG/MAG welding

66 Item No.: 099-004833-EWM01

5.2.10.3 Powercontrol program torch with one rocker (special function)

Calling up welding JOBs (block JOB mode)

In this operating mode, a total of 27 JOBs (welding tasks) divided into three blocks can be called

up using the torch.

Only program 1 can be used in these JOBs. Simultaneous operation with interfaces such as RINT

X11, BUSINT X10 or DVINT X11 is not possible.

Operating elements Functions

Torch trigger Welding on/off

Rocker Call up 27 JOBs (welding tasks) in three blocks. (see table)

8

7 segment display Shows the relevant JOB number assignment (see table).

The following configurations need to be made in order to use this special function:

• Switch the "Program or Up/Down function" changeover switch to "Program" (see "Internal operating

elements" chapter).

• Switch on Block mode (see "Organising JOBs" chapter)

• Select special JOB 1,2 or 3 (see "Organising JOBs" chapter)

Special JOB 1 (SP1) corresponds to JOB number 129,

Special JOB 2 (SP2) corresponds to JOB number 130,

Special JOB 3 (SP3) corresponds to JOB number 131.

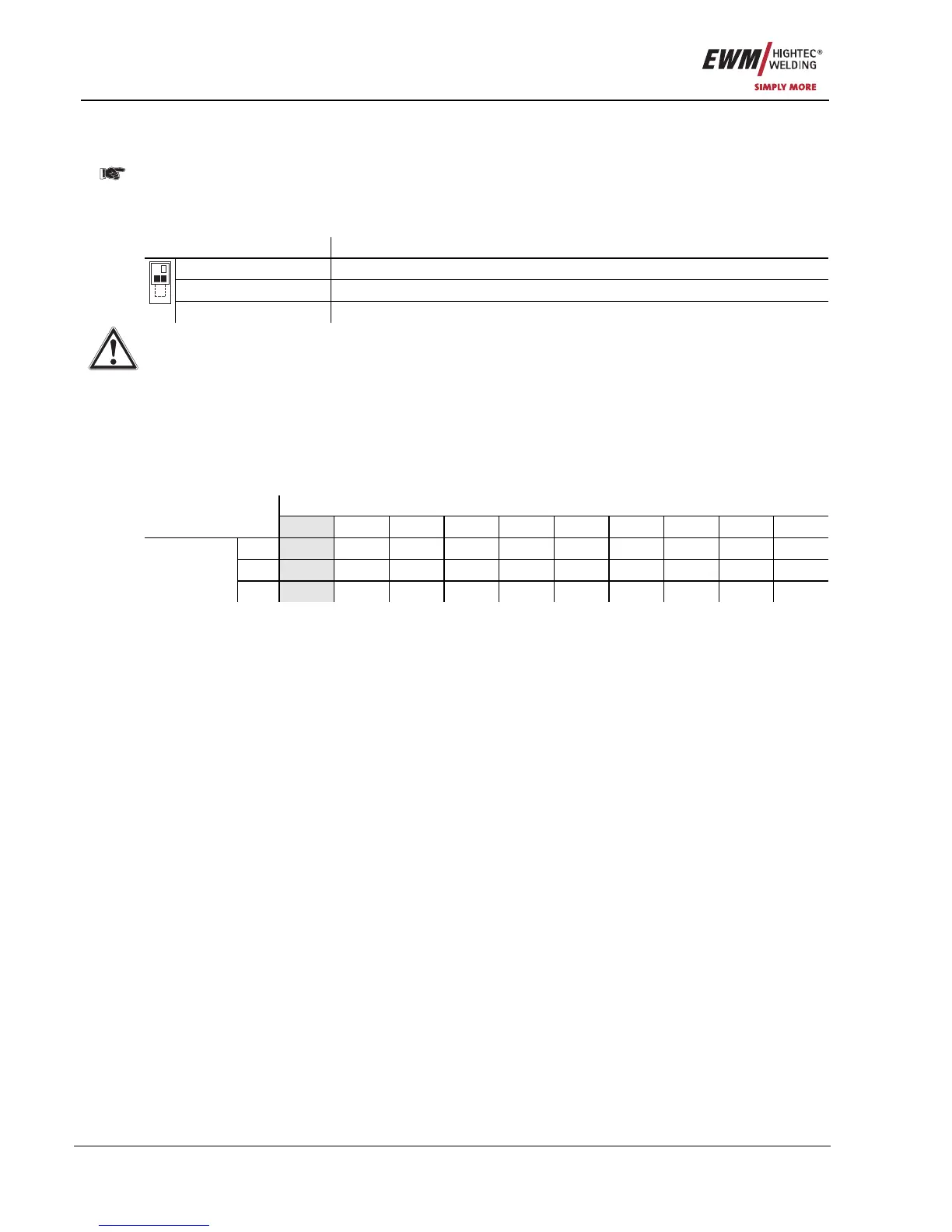

Table: Program torch JOB assignment

Welding torch selection

JOB no.

0 1 2 3 4 5 6 7 8 9

SP1

129 140 141 142 143 144 145 146 147 148

SP2

130 150 151 152 153 154 155 156 157 158

Control

selection

SP3

131 160 161 162 163 164 165 166 167 168

JOB "0" on the program torch:

Setpoint values for wire speed, arc correction and dynamics are specified manually on the wire feed unit

control. The Special JOB signal light is on permanently.

All other JOBs on the program torch:

Nine additional JOBs can be called up in each special JOB (see table). Setpoint values for wire speed,

arc correction, dynamics and other parameters must first be stored in the JOB using the welding machine

control or the PC300.Net software. (see also "Organising JOBs" chapter). The Special JOB signal light

flashes.

Loading...

Loading...