4-29

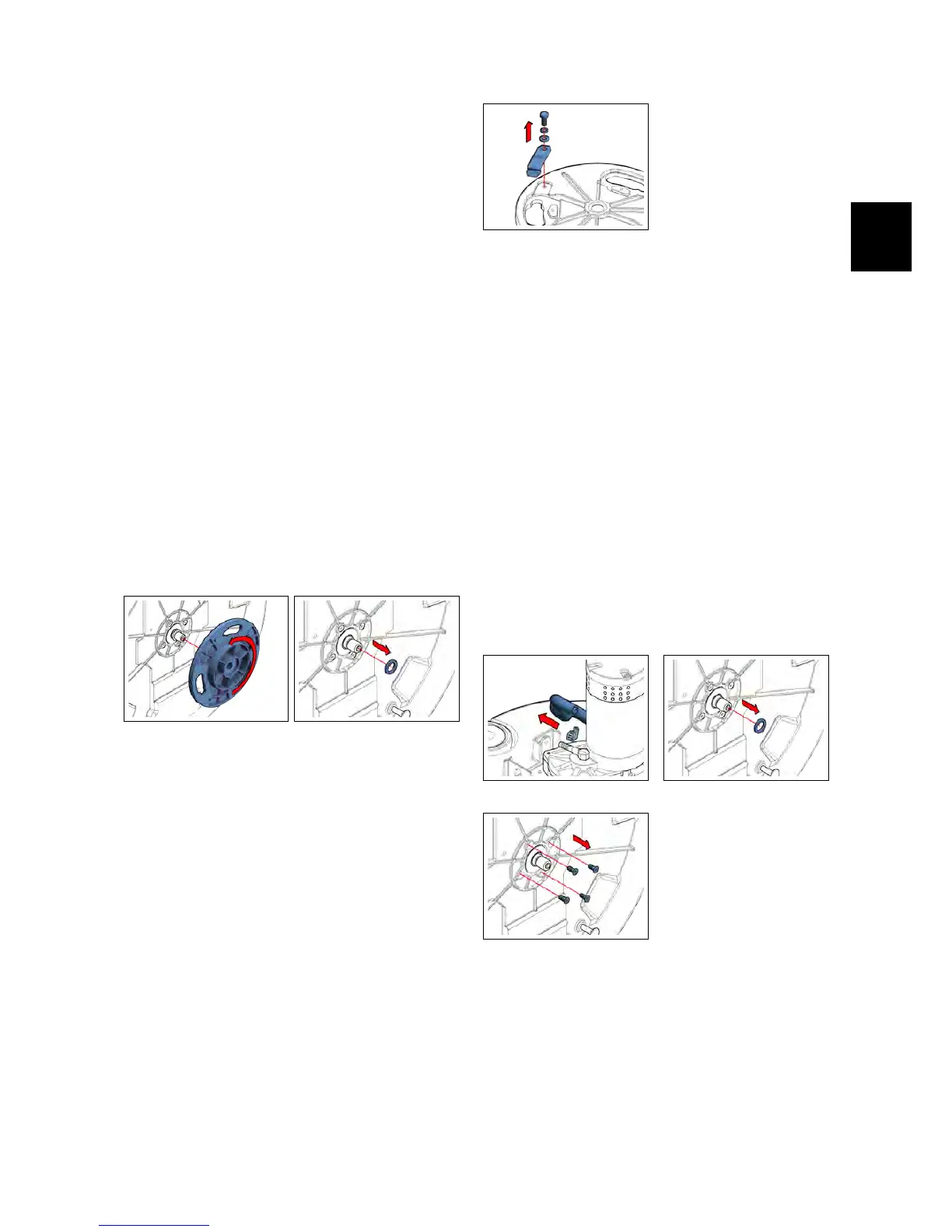

4.2.3 Brush Coupling Flange

• Put the machine in safe conditions.

• Disassemble the Brush Deck from

the machine (see section 4.2.2 at page 23).

• Put the Brush Deck to let the Motor

Head touch the floor (or a table).

• Unscrew the Coupling Flange rotat-

ing it in the same direction as the

brush in standard working condi-

tions (see fig. 4.2.3-36).

• Remove the spacer (see fig. 4.2.5-40).

• Proceed at reverse to refit the part.

Note: Before to refit the part lubricate

the thread in order to prevent blockings

because of dirt or oxide.

4.2.3-36 4.2.3-37

4.2.4 Brush Stopper Spring

• Put the machine in safe conditions.

• Disassemble the Brush Coupling

Flange (see section 4.2.4 at page 24).

• Loose the screw that block the

Brush Stopper Spring.

• Remove the Brush Stopper Spring

(see fig. 4.2.4-38).

• Proceed at reverse to refit the part.

4.2.4-38

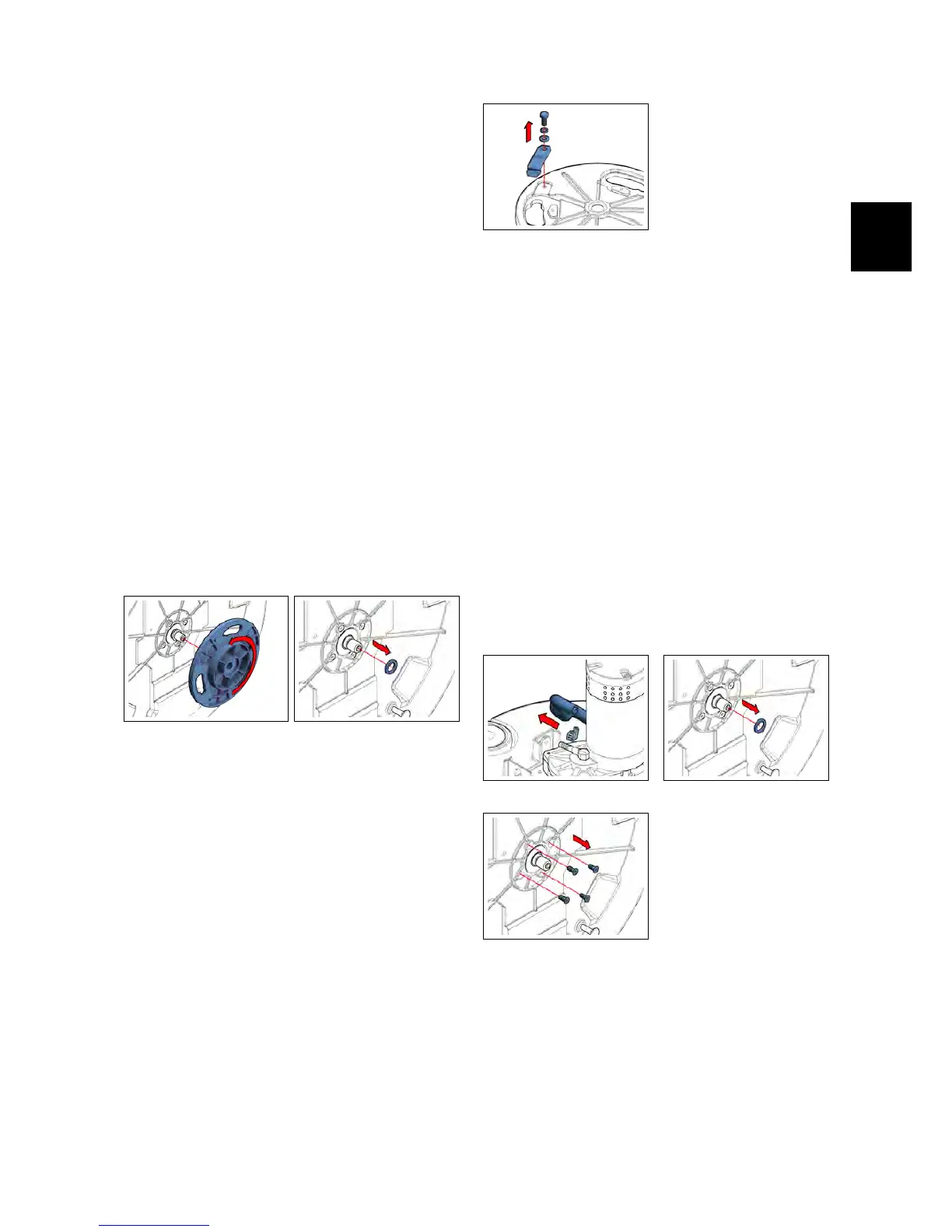

4.2.5 Brush Motor

• Put the machine in safe conditions.

• Disassemble the Brush Coupling

Flange (see section 4.2.4 at page 24).

• Unplug the Solution Hose that con-

nects the Solenoid Valve to the

Brush Motor (see fig. 4.2.5-39).

• Loose the 4 blocking screws and re-

move the Brush Motor (see fig. 4.2.5-41).

• Proceed at reverse to refit the part.

Note: Use the thread lock liquid on the

screw during the assembling.

4.2.5-39 4.2.5-40

4.2.5-41

Loading...

Loading...