7-75

Maintenance

• Put the machine in safe conditions.

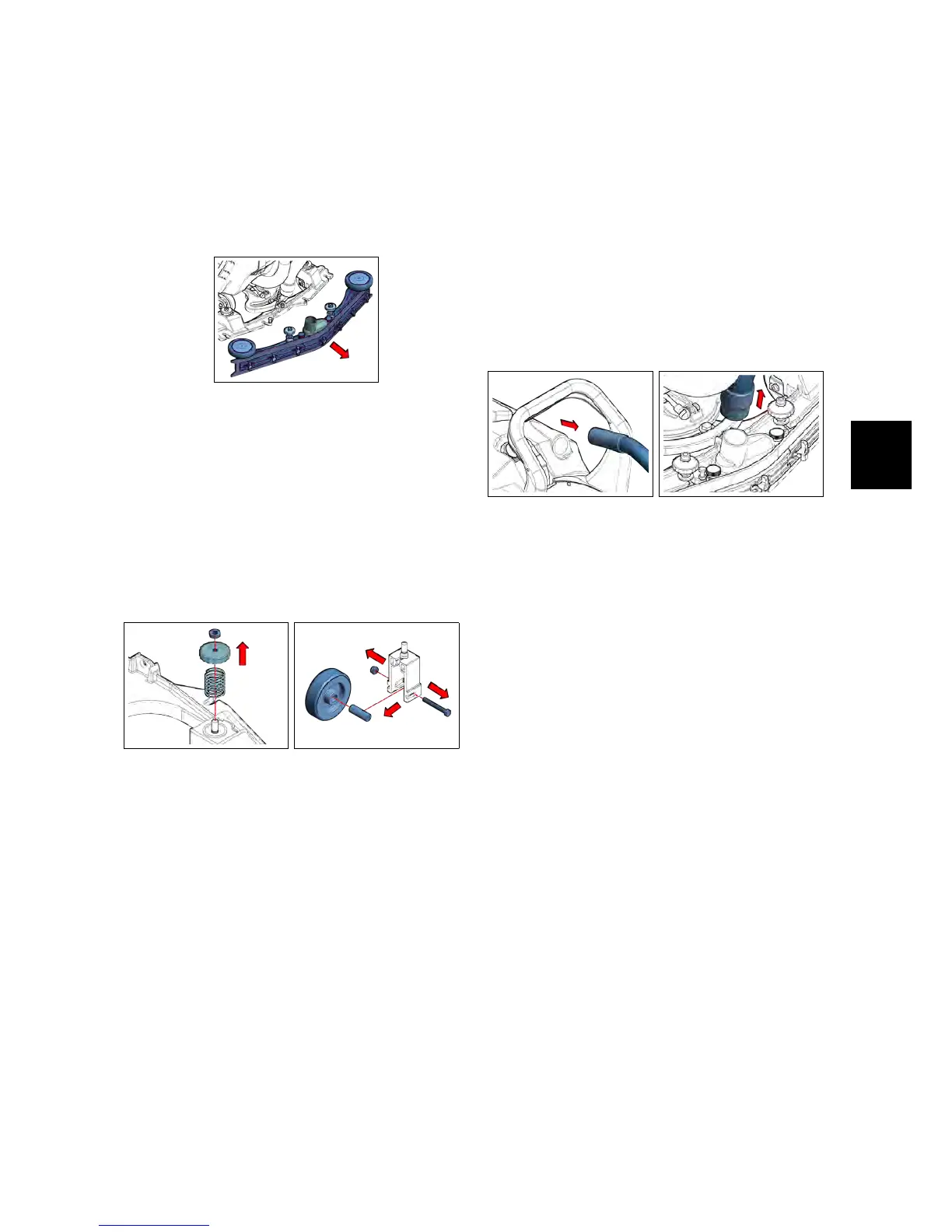

• Remove the squeegee from the

squeegee support (see fig. 7.4.2-17), (see sec-

tion 4.3.1 at page 26).

7.4.2-17 Squeegee Re-

moval

• Remove and replace the squeegee

support wheels loosing the adjust-

ment wing nuts (see fig. 7.4.2-18) and the

squeegee wheels screws (see fig. 7.4.2-19),

(see section 4.3.4 at page 27)

7.4.2-18 Adjustment

Wing Nut Removal

7.4.2-19 Blocking Screw

Removal

• Proceed at reverse to reinstall the

parts.

• During the assemblying lubricate

the squeegee support eyelet.

• At the end of the assemblying per-

form the proper squeegee adjust-

ment (see fig. 7.3.1-9), (see fig. 7.3.1-10)

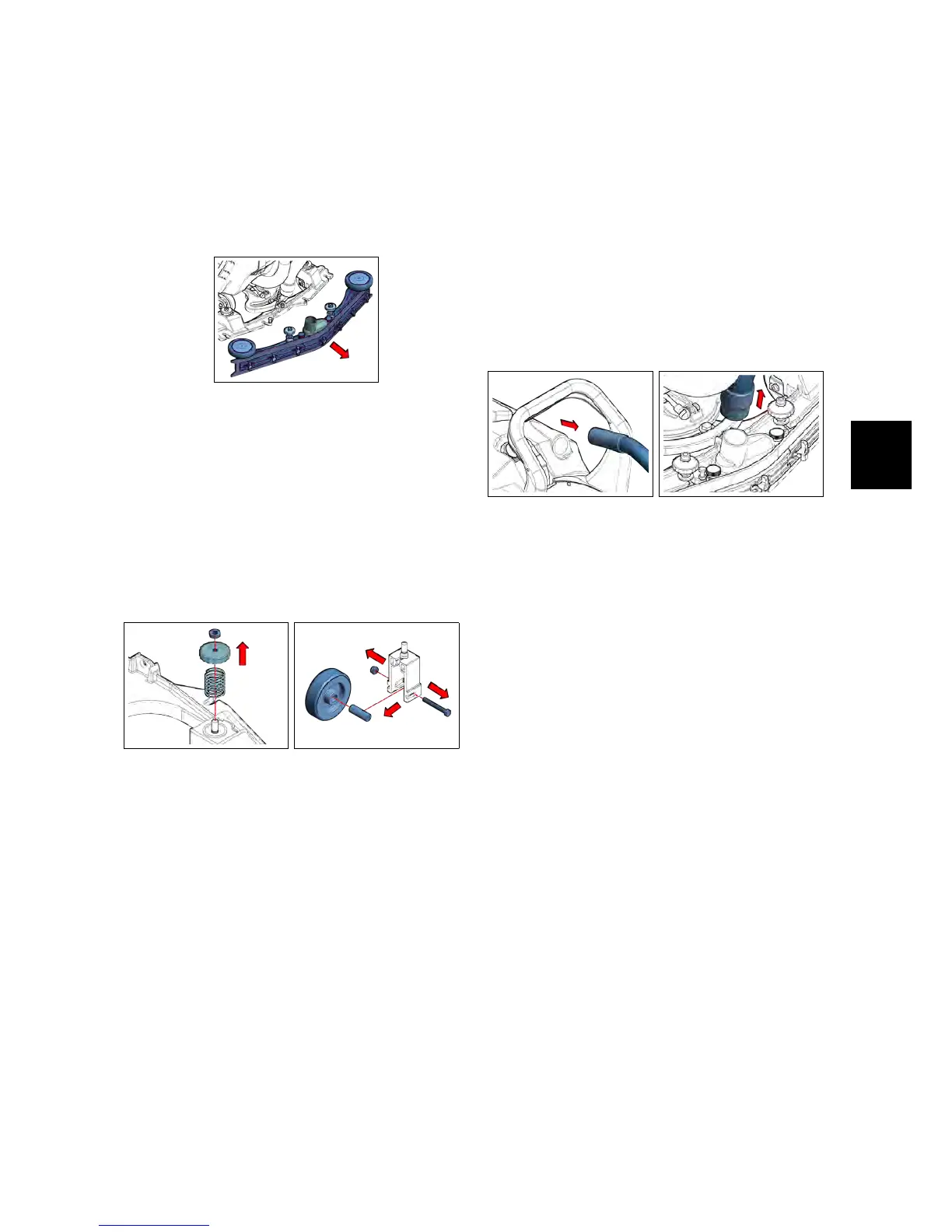

7.4.3 Vacuum Hose

Checks

The vacuum hose has to be clean and

intact (see fig. 7.4.3-20), (see fig. 7.4.3-21). It is

mandatory that the hose has no crack to

not decrease the underpressure. To ver-

ify the vacuum hose goodness turn on

the vacuum motor and block the lower

part of the hose with the hand, in this

way there must be no air passage.

7.4.3-20 Vacuum Hose 7.4.3-21 Vacuum Hose

7.4.4 Filter and Floater

Checks

The filter has to be clean and it is impor-

tant that nothing blocks or reduces the

floater mobility. The filter has to be clean

to avoid that water or dirt goes inside the

vacuum motor, the floater has to be free

to move and has to block completely the

air flow when it is in blocking position

(UP).

Maintenance

• Put the machine in safe conditions.

• Check that the recovery tank is com-

pletely empty.

• Remove the Recovery tank lid (see fig.

7.4.4-22).

• Loose the filter protection and re-

move the filter (see fig. 7.4.4-23), (see fig.

7.4.4-24). Verify that the filter ball is

free to move and intact.

Loading...

Loading...