9-84

9.3 Maintenance and

Checks

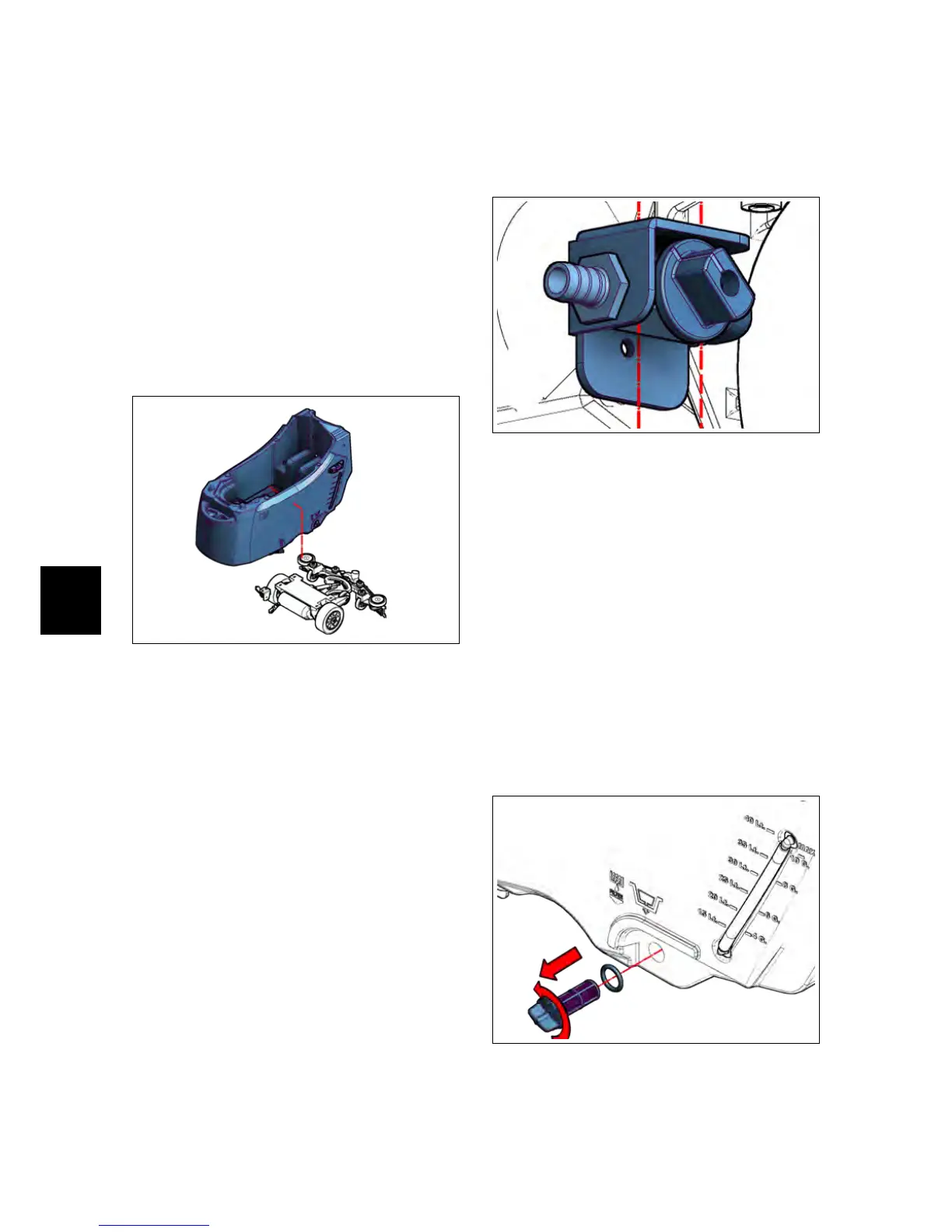

9.3.1 Solution Tank

Controls:

The solution tank has to be clean and

intact. It has not to have cracks or any

other kind of damage. Verify, when the

tank is completely filled up, that there

are not leakage. If necessary replace the

Solution Tank. (see section 4.5.1 at page 35).

Figure 9.1: Solution Tank

9.3.2 Hoses

Checks:

Every single hose has to be intact and

has not to be worn out. It is extremely

important that the hoses kept the orig-

inal flexibility and they haven’t suffered

any chemical reaction with the detergent

used with the machine. If necessary pro-

ceed with the replacement of the dam-

aged hoses (see section 4.5.2 at page 36).

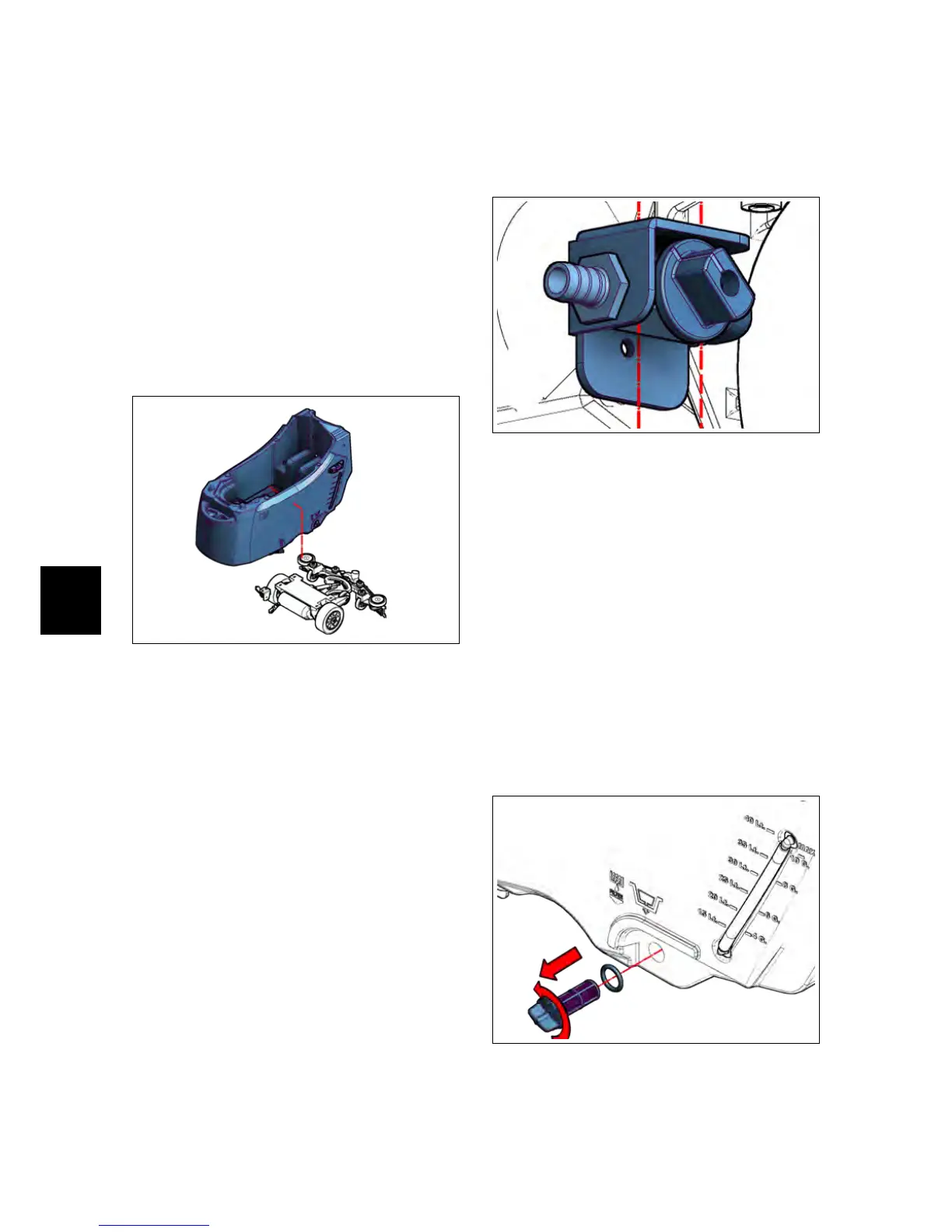

9.3.3 Water Valve

Checks:

It is extremely important that when ad-

justed at minimum the valve blocks

completely the water flow and it is me-

chanically free to move for its while

stroke.

Figure 9.2: Water Valve

9.3.4 Clean Water Filter

Checks:

The filter has to be periodically cleaned.

When it is fitted on the machine no leak-

age has to be present. The filter cartridge

has to be intact and has not to present

any anomaly.

Figure 9.3: Clean Water Filter

Loading...

Loading...