21

EN

General

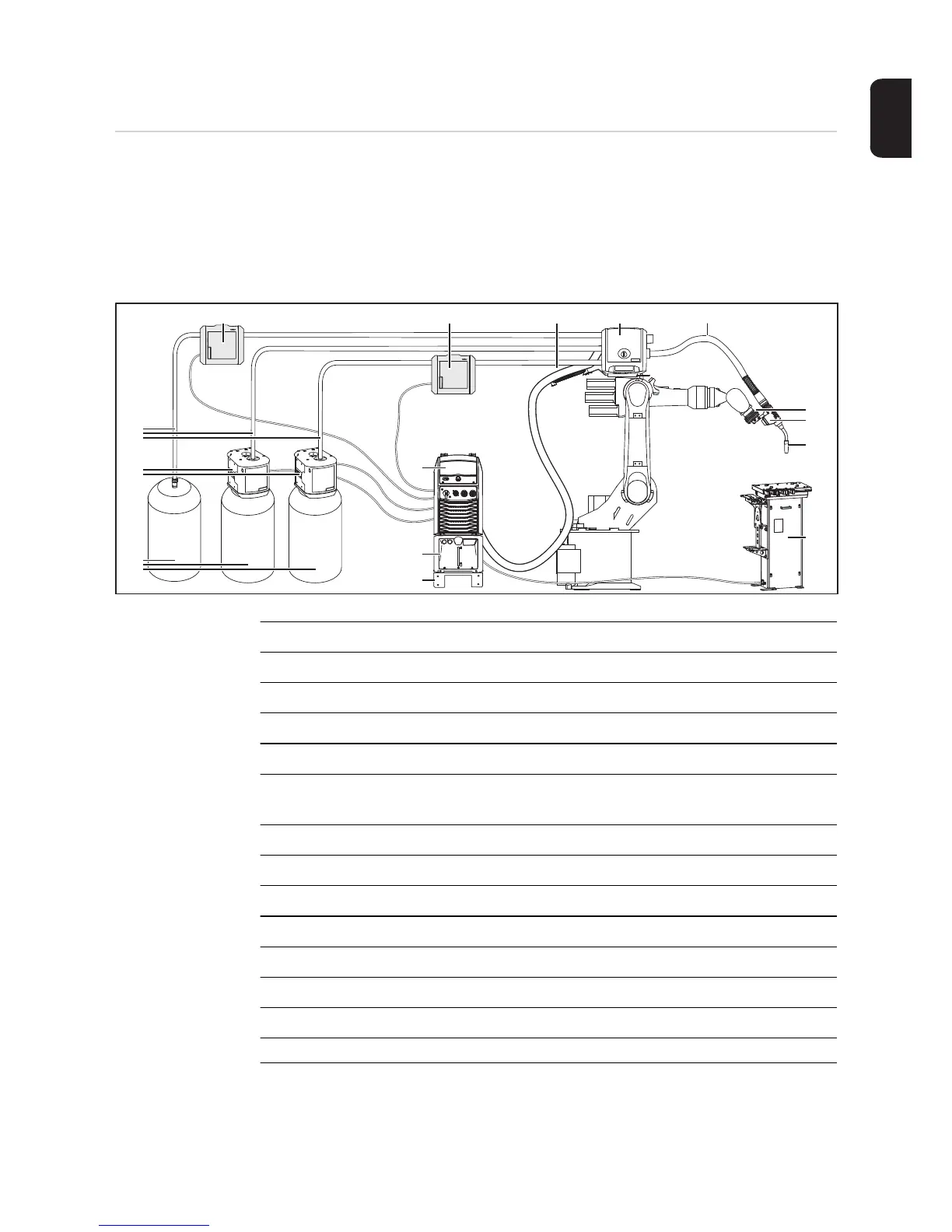

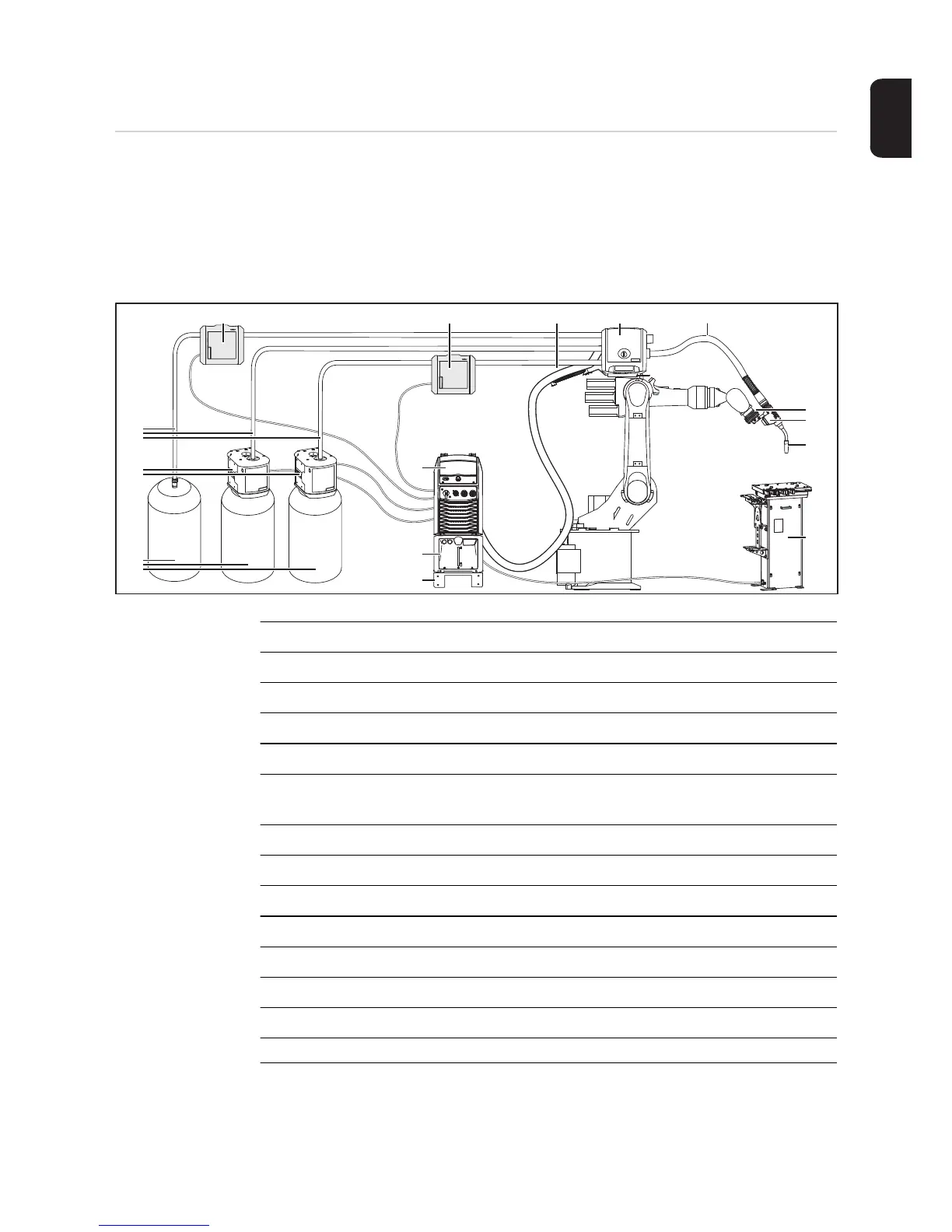

Overview of the

conventional TPS

/i welding system

with internal wire-

feeding hose

The conventional TPS/i welding system with internal wirefeeding hose is available in two

different variants:

- Variant A: with an unreeling wirefeeder (4)

- Variant B: with an unreeling wirefeeder (2)

- Variant C: with two unreeling wirefeeders (2) and (4)

The variants differ in terms of the possible wirefeeding distance.

(1) Wire drum

(2) Unreeling wirefeeder, for example WF 30 R REEL 2R

(3) Wirefeeding hose

(4) B only: Unreeling wirefeeder, for example WF 30 R REEL 2R

(5) Interconnecting hosepack

(6) Media splitter, for example SB 500i R

"QuickConnect" option

(7) Torch hosepack

(8) CrashBox and robot flange

(9) WF 25i Robacta Drive

(10) Robot welding torch

(11) Service station, for example Robacta TX/i

(12) Trolley or upright console

(13) Cooling unit, for example CU 1400i Pro

(14) Power source, for example TPS 320i

A

BC

max.

15 m

max.

8 m

max. 15 m

max. 15 m

max. 15 m

(1)

(12)

(13)

(14)

(3)

(2)

(8)

(9)

(10)

(11)

(5)(4)(4) (6) (7)

Loading...

Loading...