39

EN

Robot welding torch

Safety

General The following torch bodies are recommended for the CMT process:

- MTB 250i / 320i / 400i / 500i / 700i: 22 - 36°

- MTB 330i: 22°

The following maximum angles are permitted during the CMT process:

- MTB 250i / 320i / 400i / 500i / 700i: 45°

- MTB 330i: 36°

The robot welding torch transmits the arc power to the workpiece. The gas or water-cooled

TPS/i welding torch is designed for use with the CrashBox /i.

The torch body has an integrated lead for gas nozzle touch sensing.

CAUTION! Risk of burns from hot torch neck, hot torch neck coupling and other

hot welding torch components. Before starting work on the torch neck, the torch

neck coupling and all other welding torch components:

- allow the torch neck, torch neck coupling and all other welding torch compo-

nents to cool down to room temperature (+25 °C, +77 °F)

- wear electrically insulated and heat protective gloves

- use a suitable tool

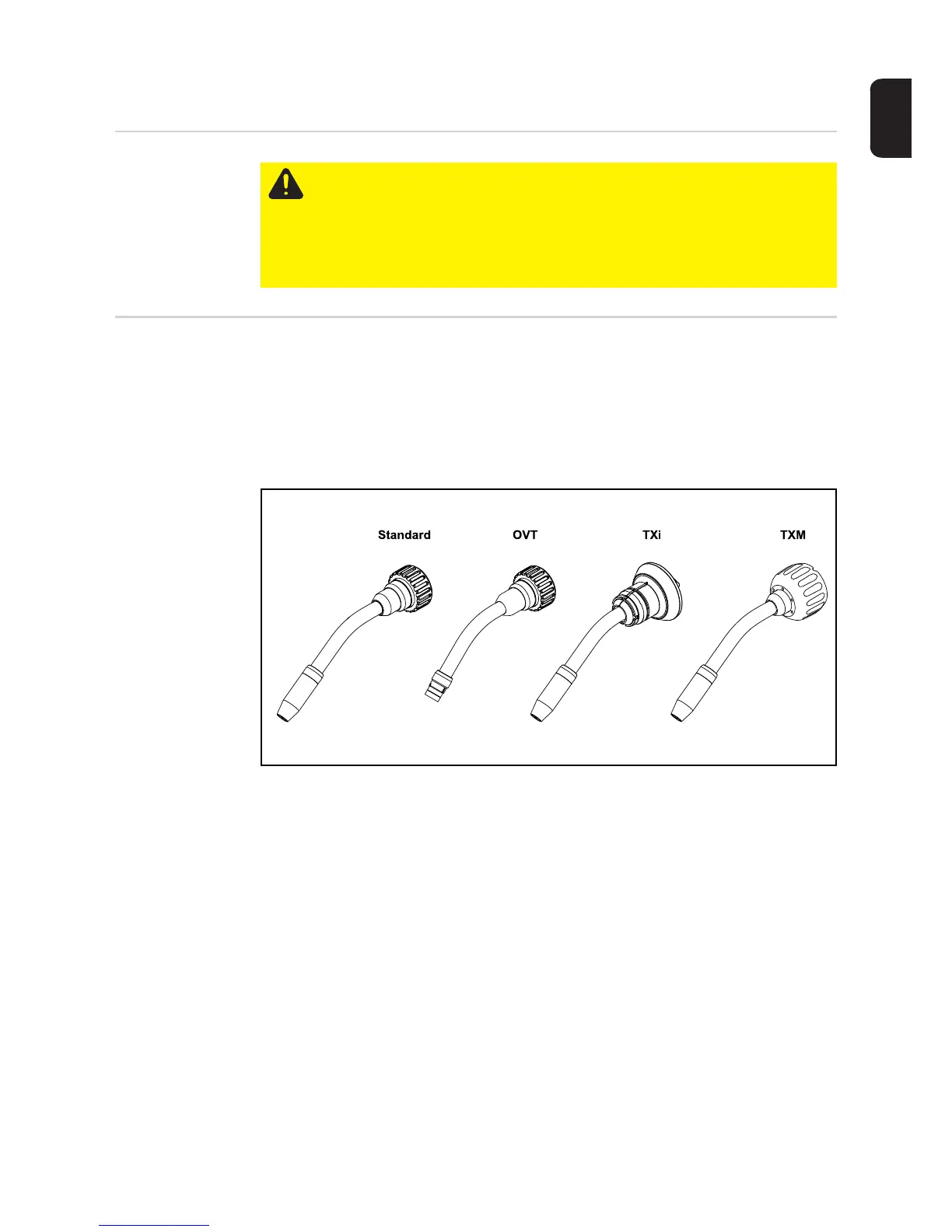

Standard: with wearing parts, without contact tip

OVT/WWP: without wearing parts

TXi: automatic torch body changeover

TXM: manual torch body changeover

Loading...

Loading...