Analog Inputs

Wire feed speed

command value

(Wire speed set

value) - Group

Input / Analog

Input

As described below, the set value can be specified on a Digital Interface or an Analog

Interface.

The following set value specifications apply to the MIG/MAG standard synergic,

MIG/MAG pulse synergic, MIG/MAG PMC, and MIG/MAG LSC welding processes.

Digital Interface:

The wirefeeder set value is specified by entering a value between -32,768 and

+32,767 (SINT 16).

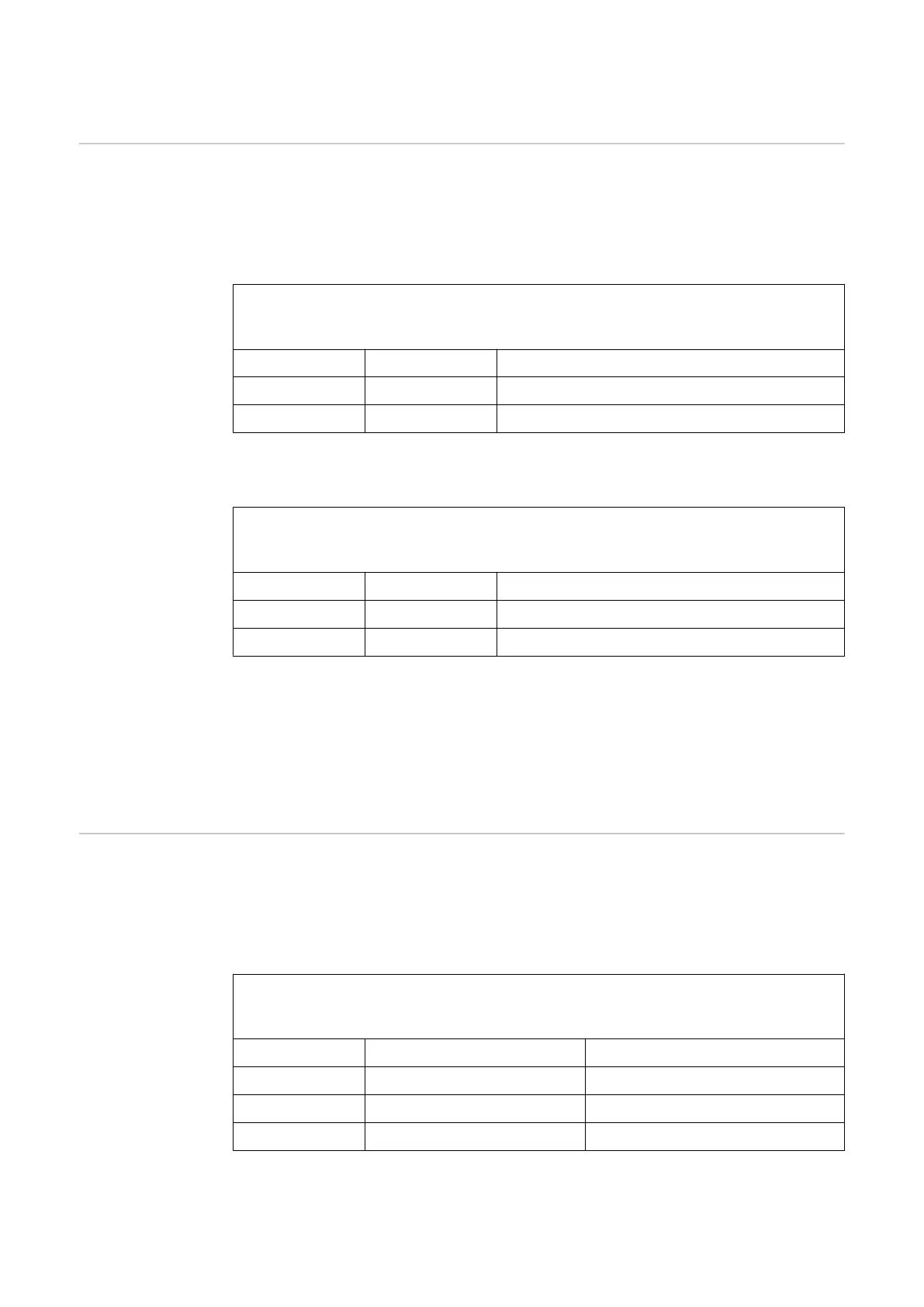

Value range Designation Min./max. possible value

-32,768 Wire speed -327.68 m/min (depending on wirefeeder)

+32,767 Wire speed +327.67 m/min (depending on wirefeeder)

Additional information for TWIN systems:

The digital set value must be entered separately for both power sources.

Analog Interface:

The wirefeeder set value is specified through an analog method by entering a value

between 0 and 10 V.

Value range Designation Min./max. possible value

0 V Wire speed 0% (depending on wirefeeder)

10 V Wire speed 100% (depending on wirefeeder)

Additional information for TWIN systems:

It is not possible to enter an analog set value on TWIN systems.

Job correction (specifications apply for Single- andTWIN welding):

- Factor = 100

- Data type SINT

- Specified as a percentage. Example: 15% = 1500 step change

Arclength correc-

tion (arc length

correction) -

Group Input /

Analog Input

As described below, the value for the arc length correction can be specified on a Digital

Interface or an Analog Interface.

The following specifications apply to the MIG/MAG standard synergic, MIG/MAG pulse

synergic, MIG/MAG PMC, and MIG/MAG LSC welding processes.

Digital Interface:

By entering a value between -32,768 and +32,767 (SINT 16) the arc length is correc-

ted, but the wire speed is not changed.

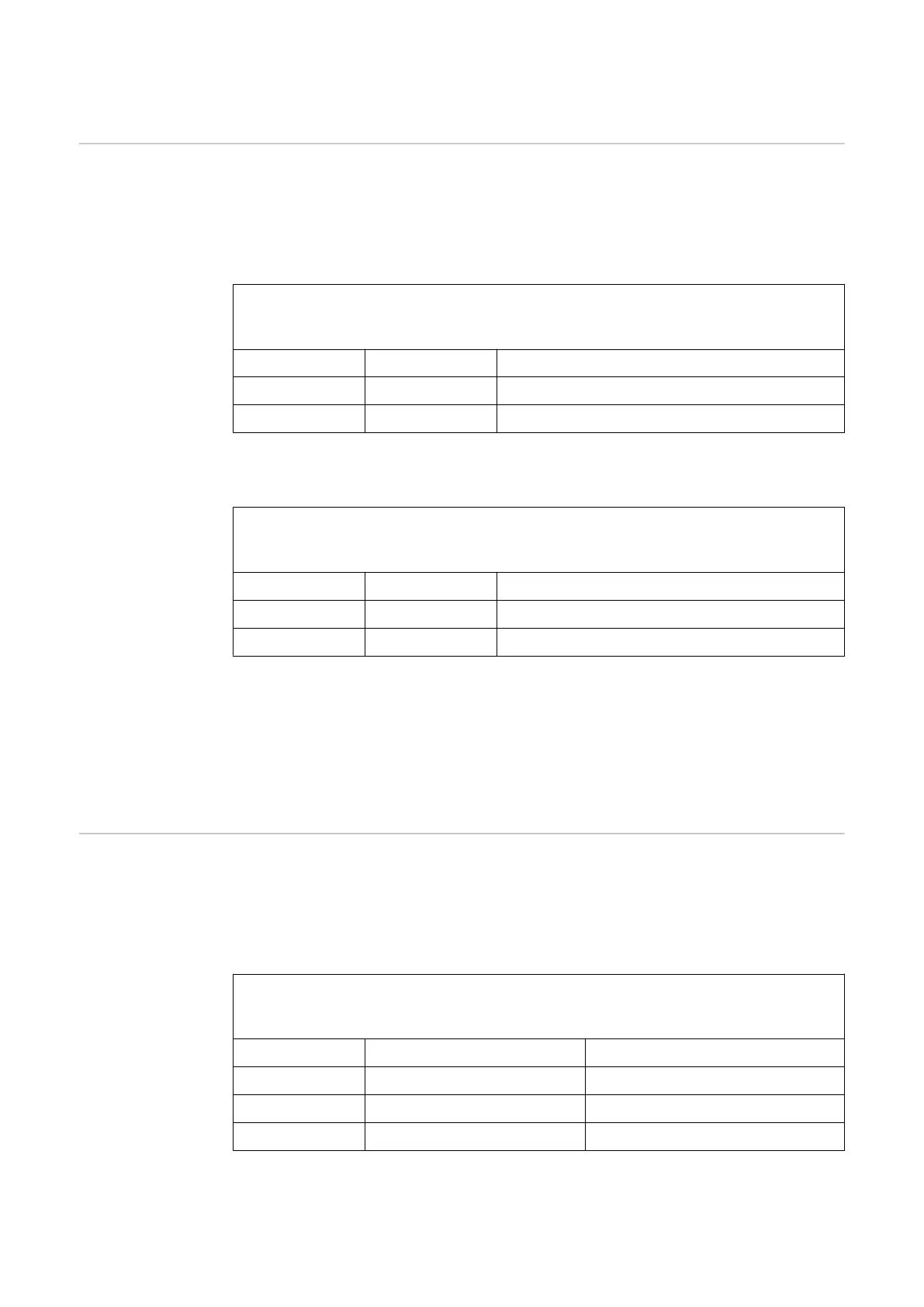

Value range Designation Min./max. possible value

-32,768 Arc length correction -10% = shorter arc

0 Arc length correction 0% = saved value

+32,767 Arc length correction +10% = longer arc

Additional information for TWIN systems:

The digital set value must be entered separately for both power sources.

20

Loading...

Loading...