General

Data Types Used UINT 16 (Unsigned Integer) = Whole number in the range from 0 to 65,535

SINT 16 (Signed Integer) = Whole number in the range from -32,768 to 32,767

Conversion examples:

- For a positive value (SINT 16) = desired wire speed x factor = 12.3 m/min x 100 =

1230

dec

= 04CE

hex

- For a positive value (SINT 16) = desired arc length correction x factor = -6.4 x 10 =

-64

dec

= FFC0

hex

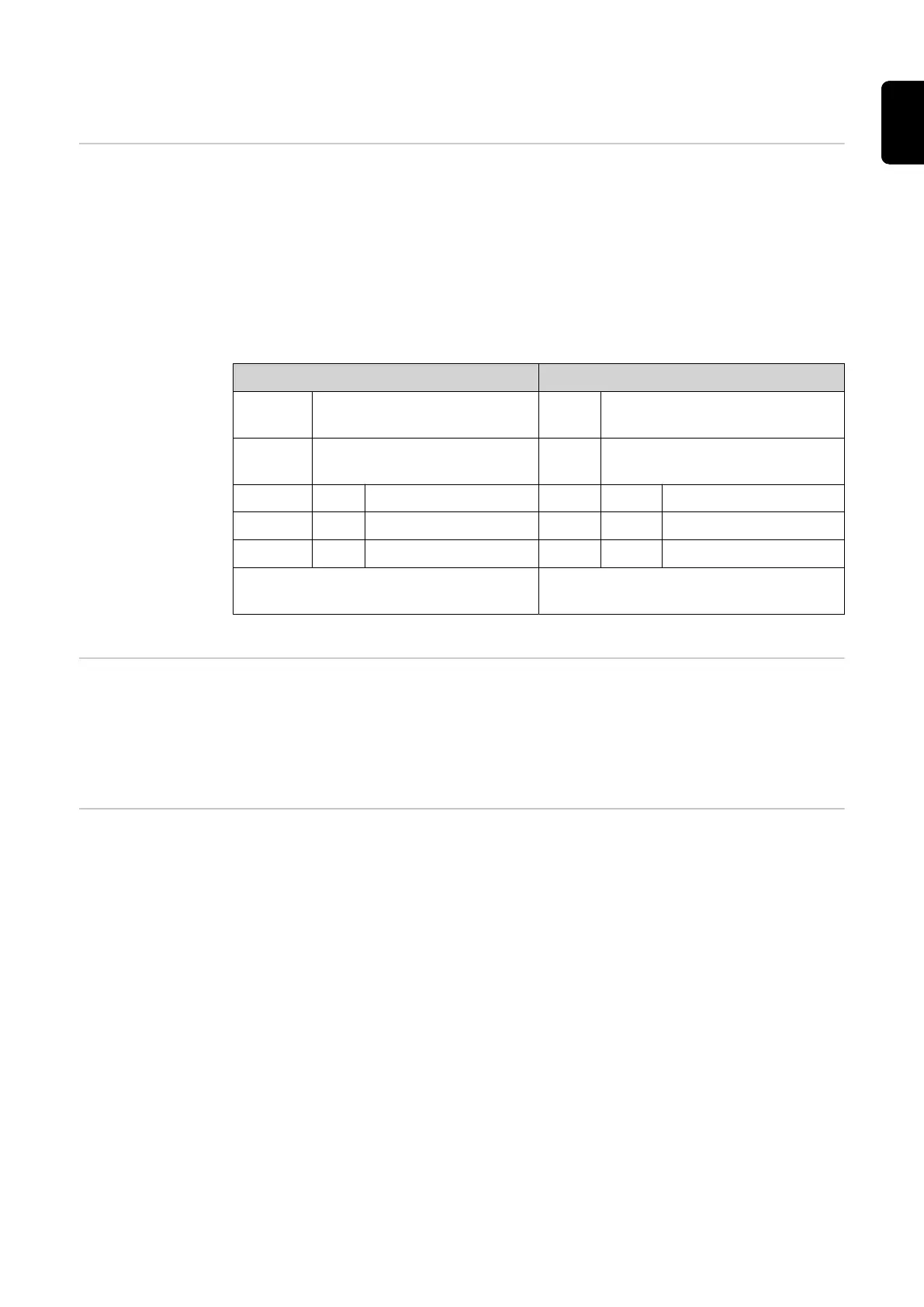

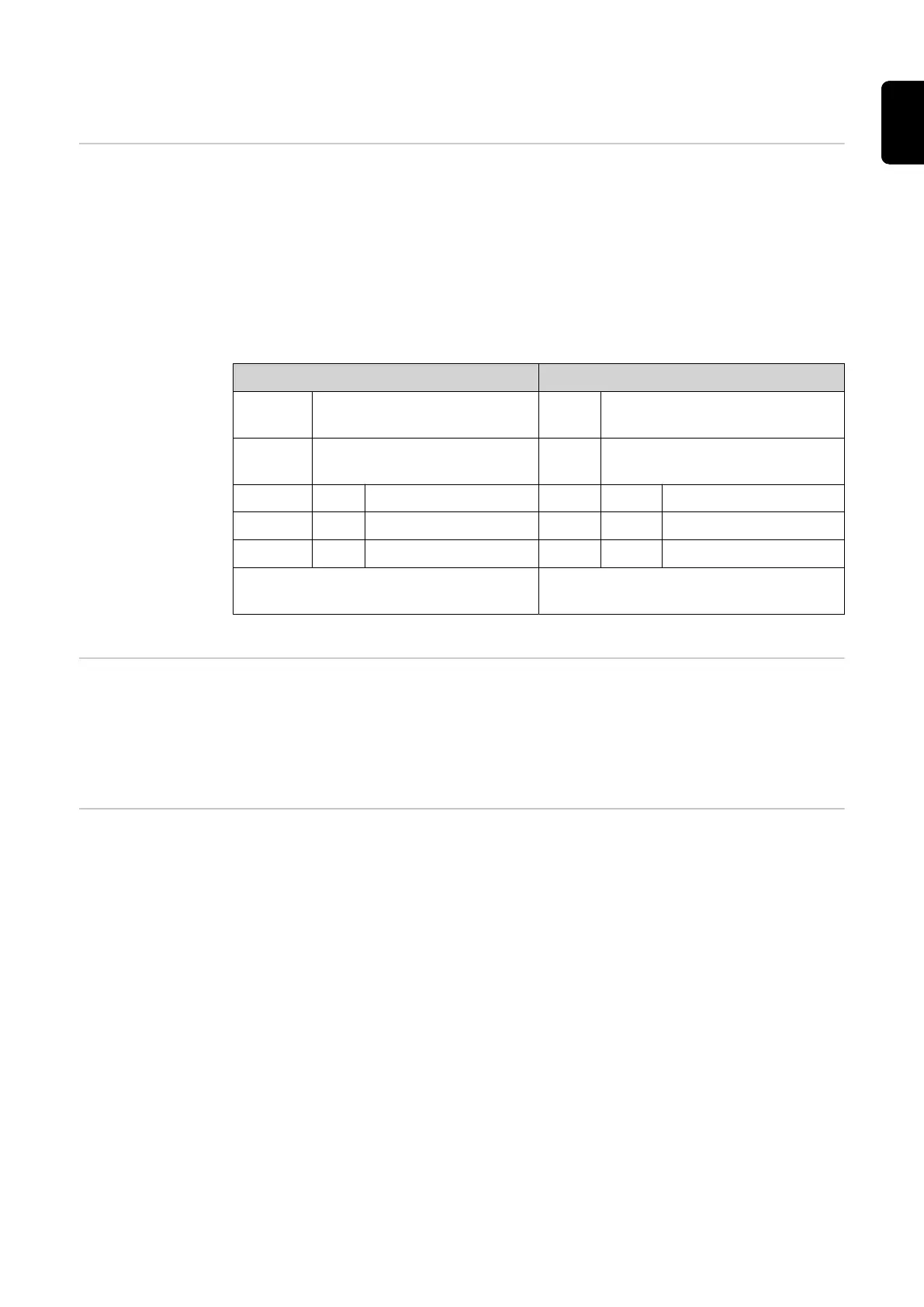

Unsigned (UINT): Signed (SINT):

Type: Unsigned 16 Bit integer = 16

bits

Type: Signed 16 Bit integer (15 bits +

1 Sign Bit*)

Range: 0 to 65535 Rang

e:

-32768 to 32767

0000 -10 (0000000000000000) 0000 0000 (0*000000000000000)

32767 0 (0111111111111111) 56 56 (0*000000000111000)

65535 +10 (1111111111111111) -64 -64 (1*111111111000000)

* = if the value entered has a negative

sign, the sign Bit is High – see markings

Behavior of the

Power Source

when an Interface

is Connected

If a power source from the TPS/i series is connected to a robot interface, the settings on

the power source remain unchanged (2-step mode, special 2-step mode, etc.).

If a power source from the TPS series is connected to a robot interface, the power

source automatically selects 2-step mode.

Availability of

Functions

As a result of updates, certain functions may be available on your device that are not

described in this document, or vice versa.

5

EN-US

Loading...

Loading...