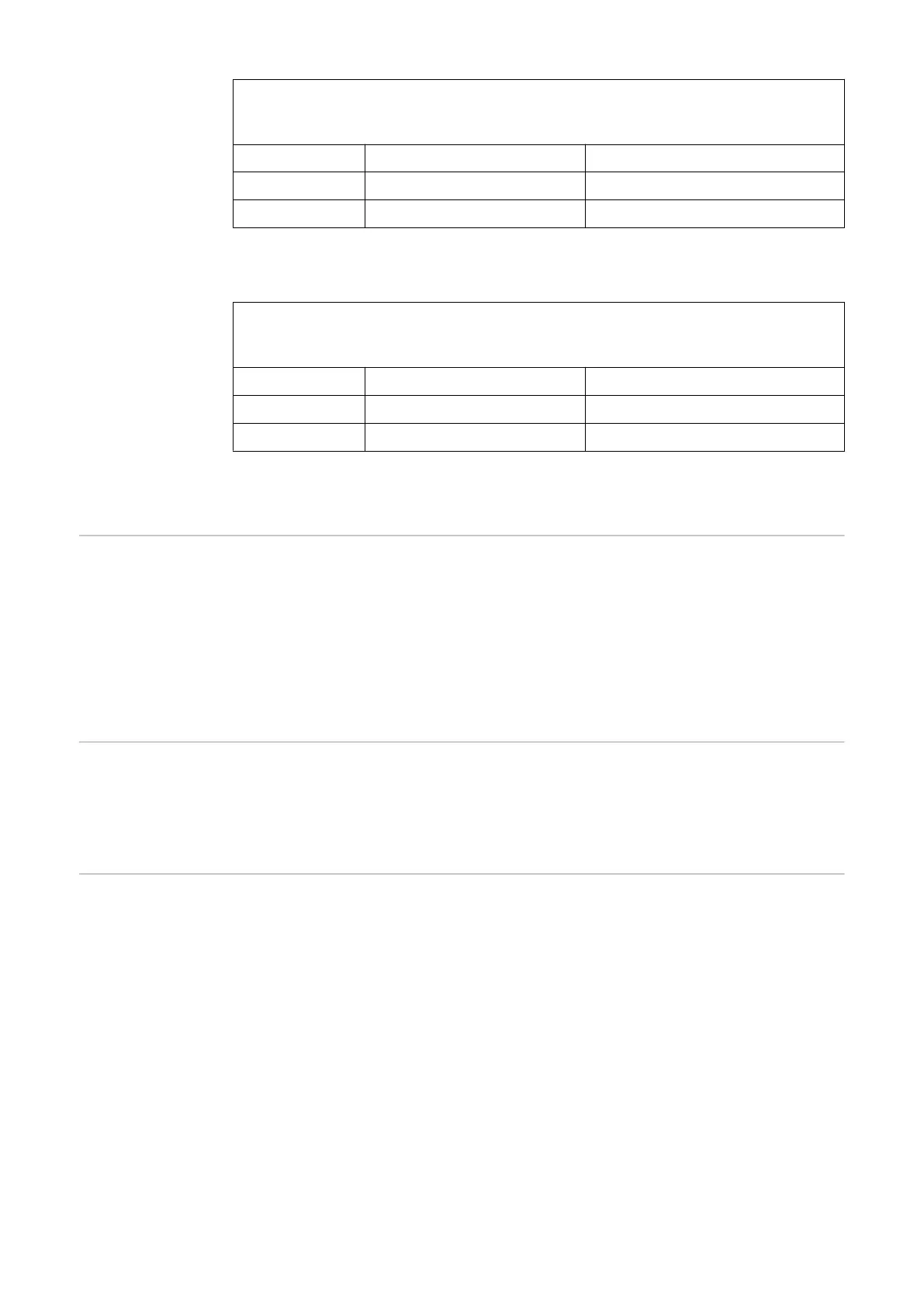

Digital Interface:

The wire retraction correction is specified by entering a value between 0 and 65,535

(UINT 16).

Value range Designation Min./max. possible value

0 Wire retraction correction 0

65,535 Wire retraction correction +10

Additional information for TWIN systems:

The digital value must be entered separately for both power sources.

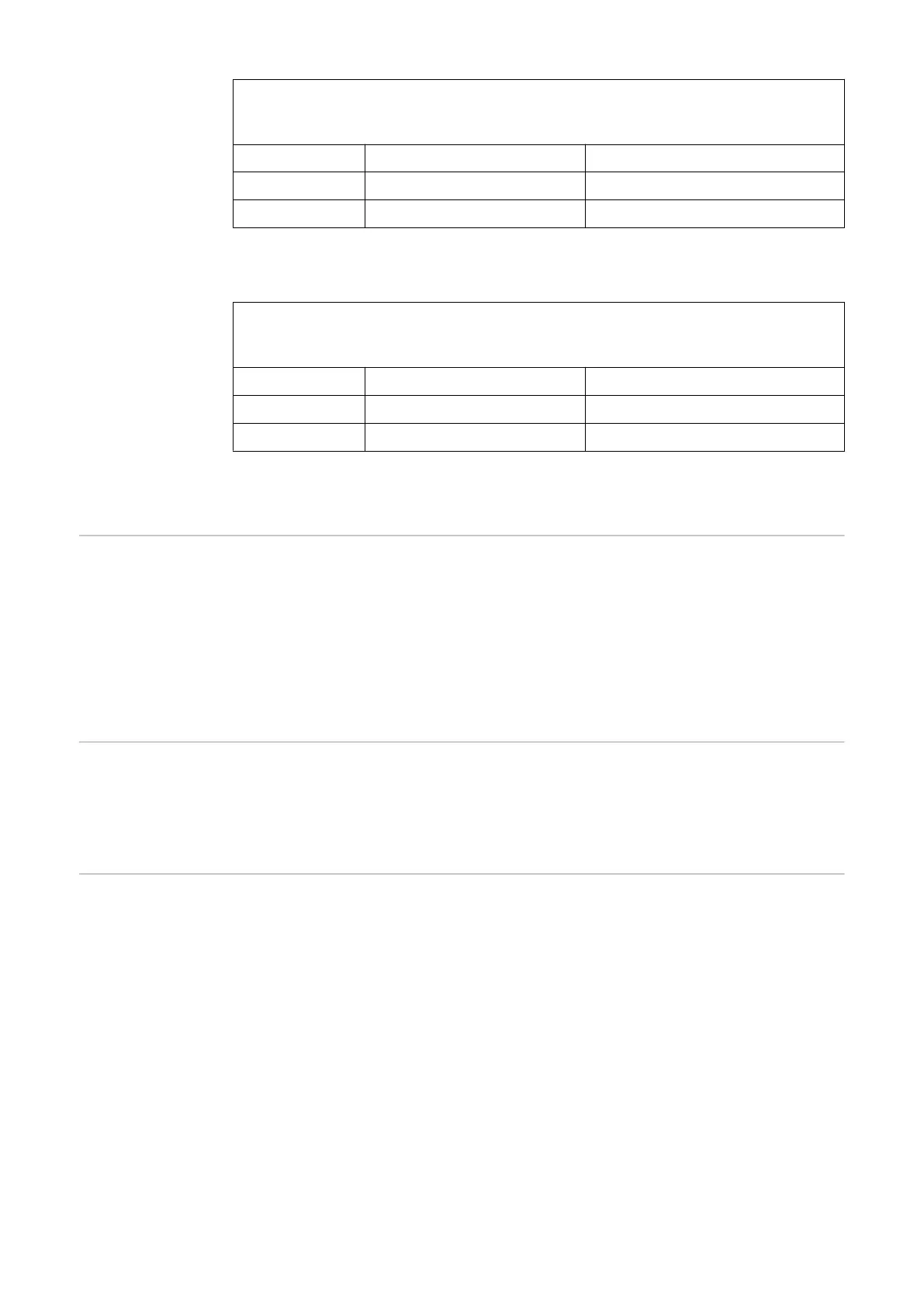

Analog Interface:

The wire retraction correction is specified by using an analog method to enter a value

between 0 and 10 V.

Value range Designation Min./max. possible value

0 V Wire retraction correction 0

10 V Wire retraction correction +10

Additional information for TWIN systems:

It is not possible to enter an analog value on TWIN systems.

Seam number

(Seam number) -

Group Input /

Analog Input

The seam number of the respective welding process is specified using this value, for

example for documentation purposes.

For more detailed information regarding weld seam documentation, please refer to Doc-

umentation mode (Documentation mode) - Single Biton page 17.

Additional information for TWIN systems:

The seam number for both power sources is specified at the same time.

Welding speed

(Welding speed) -

Group Input /

Analog Input

This value is used to transmit the robot's TCP speed.

Additional information for TWIN systems:

The TCP speed for both power sources is transmitted at the same time.

WireSense edge

detection - Group

Input / Analog

Input

Contour detection:

- If a value less than 0.5 mm (0.019 inches) is specified with the WireSense edge

detection signal, the WireSense start signal is used for contour detection (Wire-

Sense - Sensing Mode)

• The surface of the component is scanned cyclically by the wire electrode and

the measured height value is output continuously

• The Touch signal is not active at the same time

22

Loading...

Loading...