Value range Designation Min./max. possible value

0 V Welding current 0 A (set value/actual value/Hold value)

10 V Welding current 1000 A (set value/actual value/Hold value)

Additional information for TWIN systems:

The analog actual value is not output on TWIN systems.

Wire feed speed

(Wire speed) -

Group Output /

Analog Output

As described below, the current wire speed actual value can be output on a Digital Inter-

face or an Analog Interface.

Digital Interface:

- During the welding process, the current wire speed actual value will be output as

a value between -32,768 and +32,767 (SINT 16) .

- The wire speed set value is output when idling.

- The Hold- value is output immediately after welding.

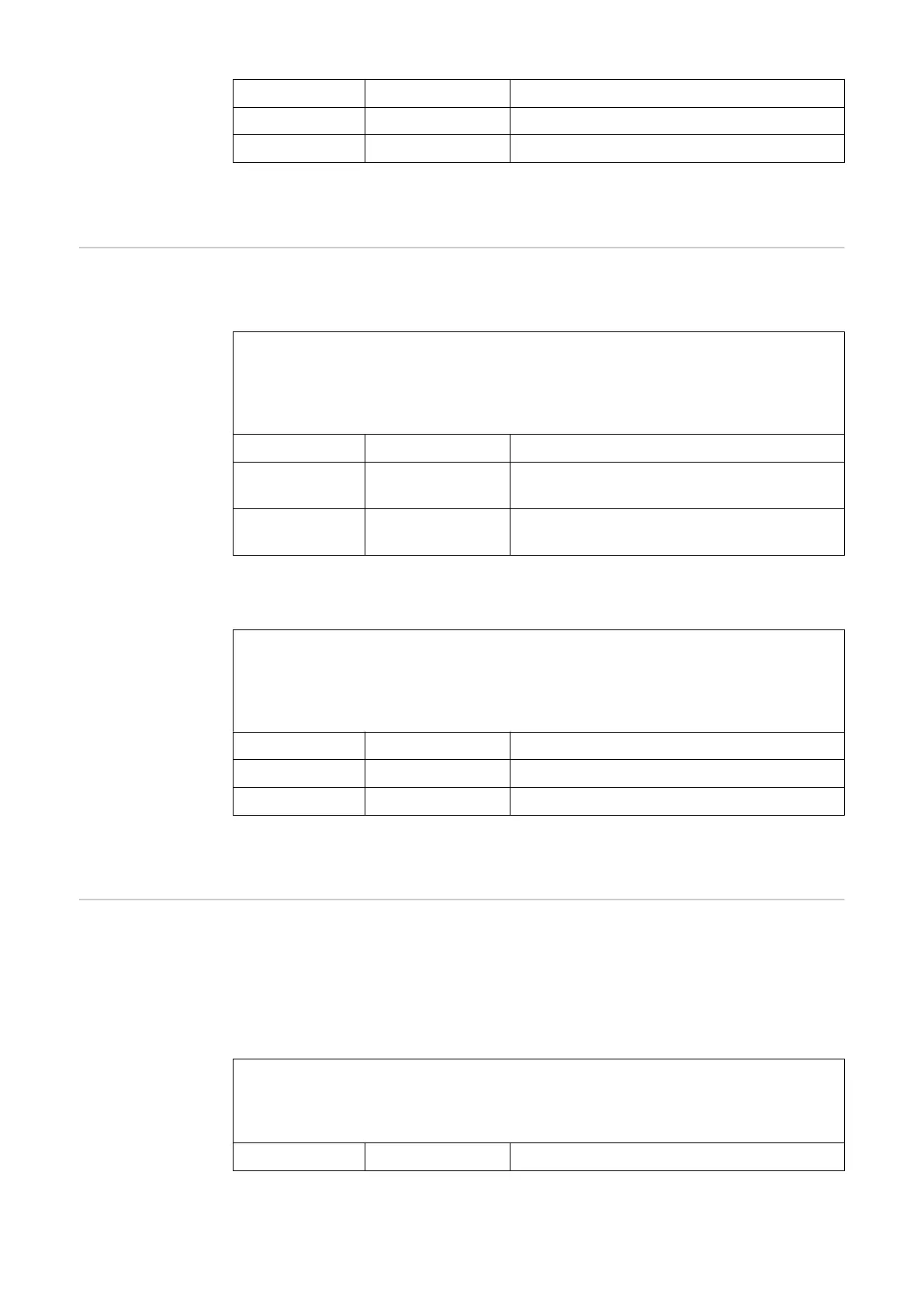

Value range Designation Min./max. possible value

-32,768 Wire speed -327.68 m/min (set value/actual value/Hold

value)

+32,767 Wire speed +327.67 m/min (set value/actual value/Hold

value)

Additional information for TWIN systems:

The digital actual value is output separately for both power sources.

Analog Interface:

- During the welding process, the current wire speed actual value will be output

using an analog method as a value between 0 - 10 V.

- The wire speed set value is output when idling.

- The Hold- value is output immediately after welding.

Value range Designation Min./max. possible value

0 V Wire speed 0 m/min (set value/actual value/Hold value)

10 V Wire speed depending on the wirefeeder used

Additional information for TWIN systems:

The analog actual value is not output on TWIN systems.

Actual real value

for seam tracking

(Current actual

value for seam

tracking) - Group

Output / Analog

Output

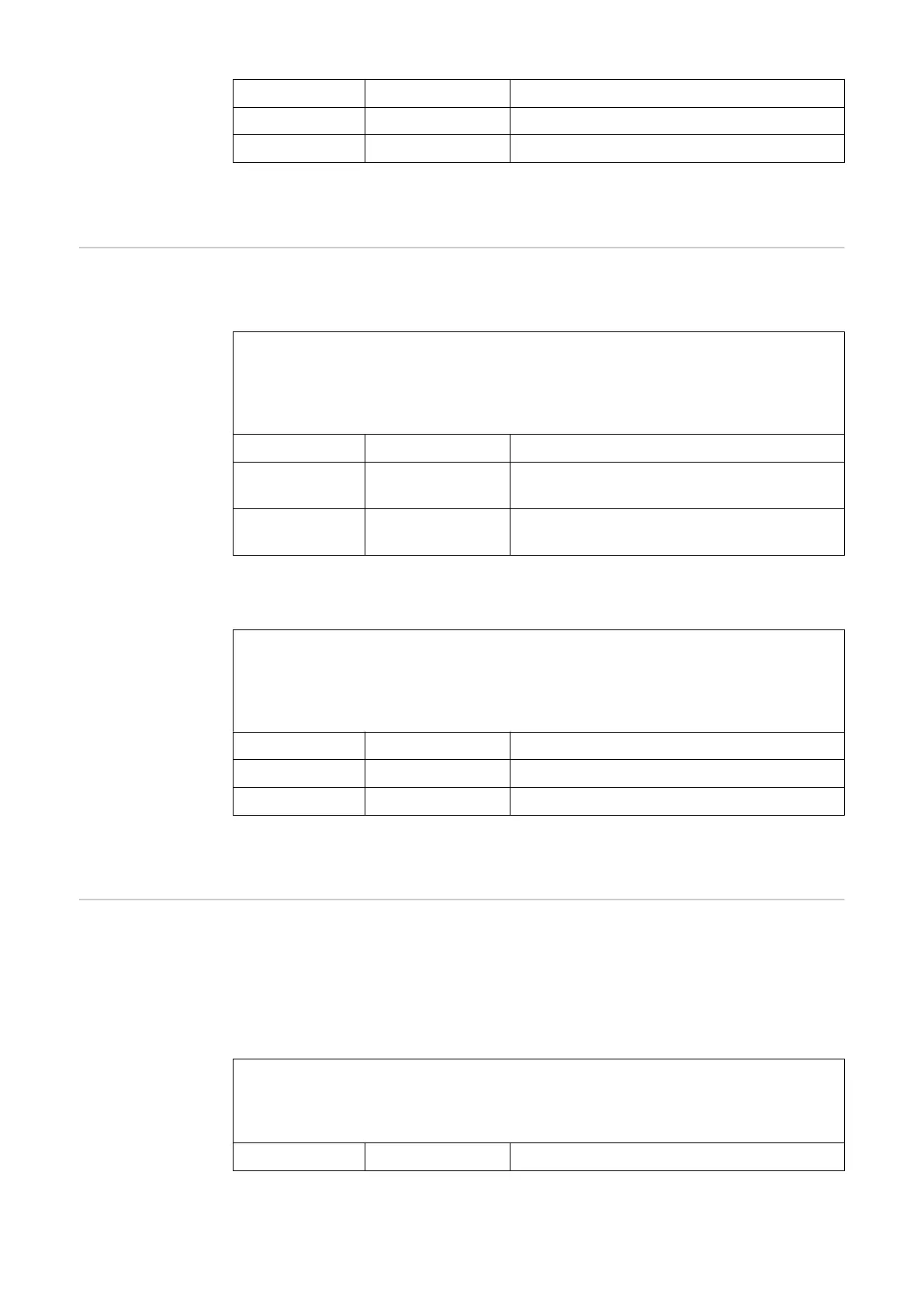

As described below, the current actual value for seam tracking can be output on a Digital

Interface or an Analog Interface.

This signal is output as standard when using MIG/MAG LSC and MIG/MAG PMC char-

acteristics. The signal is available upon request for MIG/MAG pulse synergic and

MIG/MAG standard synergic characteristics.

Digital Interface:

- During the welding process, the current actual value for seam tracking will be

output as a value between 0 and 65,535 (UINT 16).

- The Hold- value is output at the end of welding.

Value range Designation Min./max. possible value

38

Loading...

Loading...