0 Current actual

value for seam

tracking

0

(depending on the position of the welding

torch)

65,535 Current actual

value for seam

tracking

10,000

(actual value/Hold- value)

Additional information for TWIN systems:

The digital actual value is output separately for both power sources.

Analog Interface:

- During the welding process, the current actual value for seam tracking will be

output using an analog method as a value between 0 - 10 V.

- The Hold- value is output at the end of welding.

Value range Designation Min./max. possible value

0 V Current actual

value for seam

tracking

0

(depending on the position of the welding

torch)

10 V Current actual

value for seam

tracking

1

(actual value/Hold- value)

Additional information for TWIN systems:

The analog actual value is not output on TWIN systems.

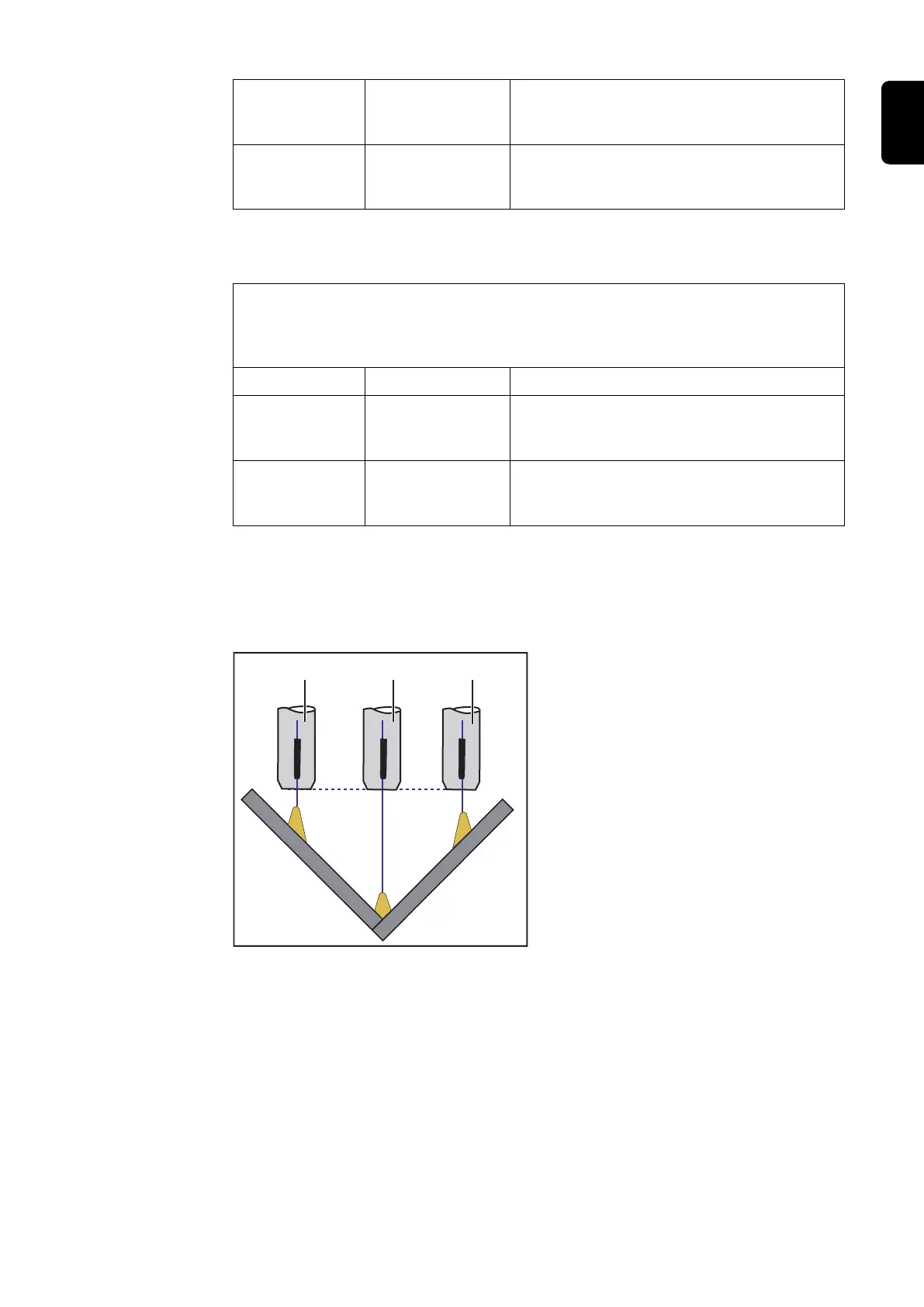

Weaving overview (current actual value for seam tracking, the values given are

for illustrative purposes only):

(1) - Stickout: 10 mm

- Wire speed: 7 m/min

- Arc length correction: 0

- Current actual value for seam

tracking: approx. 7650

(2) - Stickout: 25 mm

- Wire speed: 7 m/min

- Arc length correction: 0

- Current actual value for seam

tracking: approx. 5853

(3) - Stickout: 10 mm

- Wire speed: 7 m/min

- Arc length correction: 0

- Current actual value for seam

tracking: approx. 7650

Weaving function overview:

- The current actual value for seam tracking is calculated using the welding current

and the welding voltage

- The current actual value for seam tracking changes with the Stickout

- The current actual value for seam tracking is between 0 and 10,000:

• Stickout becomes shorter – signal increases

• Stickout becomes longer – signal reduces

39

EN-US

Loading...

Loading...