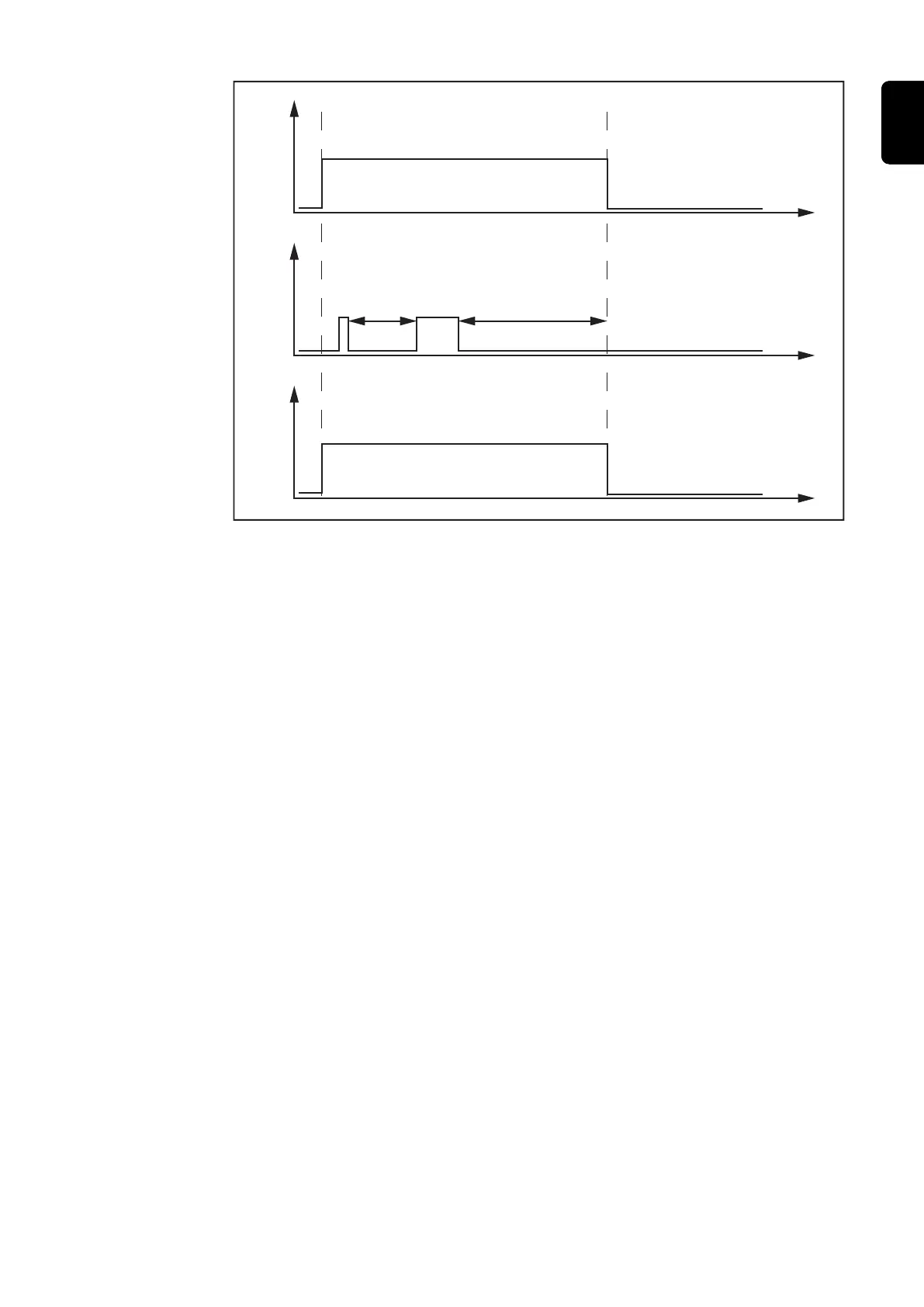

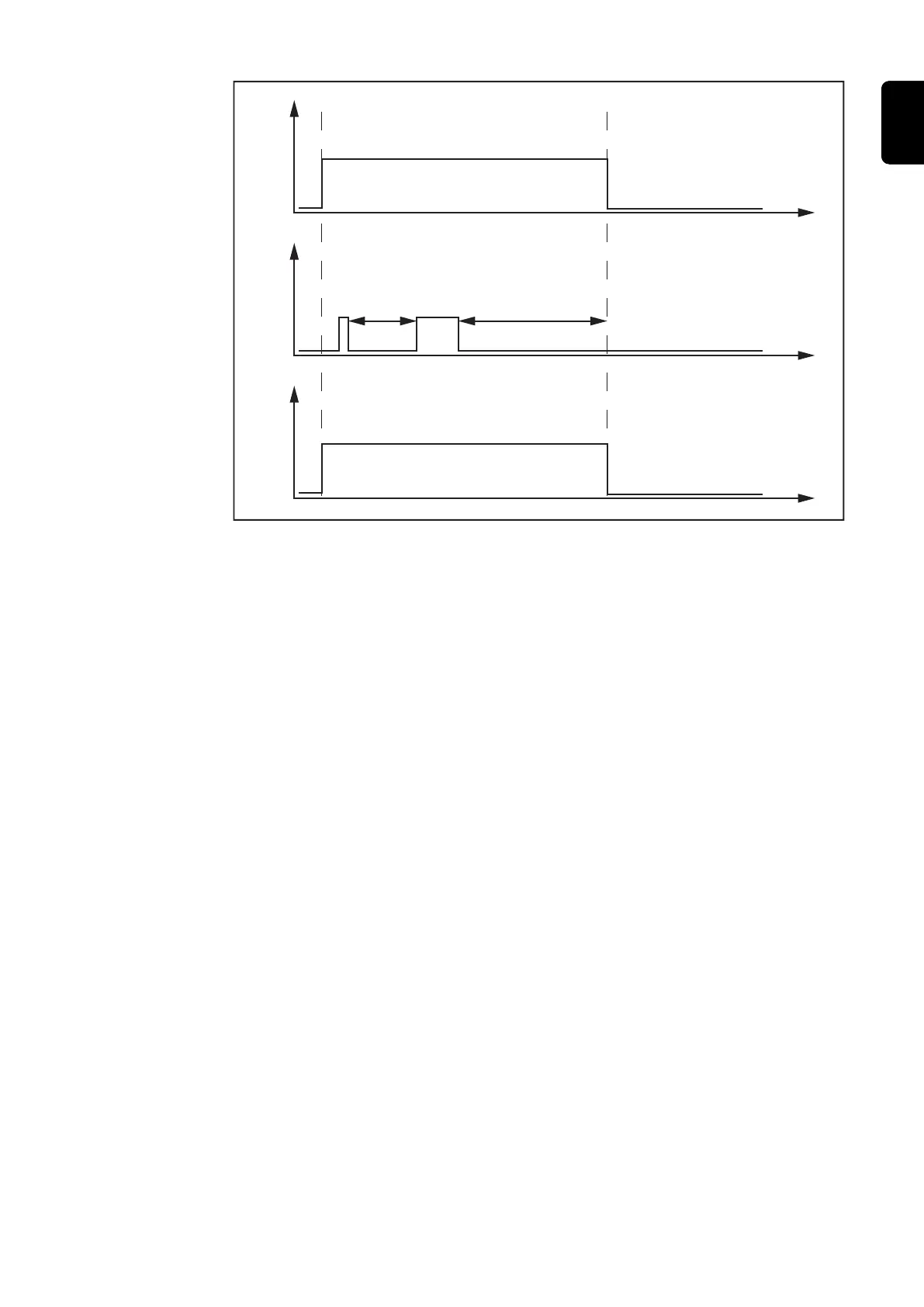

t

Current flow

(Digital Output)

Arc stable

(Digital Output)

t

Welding start

(Digital Input)

arc break

<190ms

t

arc break

<200ms

(1)

Example of Arc Break Monitoring Behavior

(1) The status of the Welding start signal is dependent on:

- The arc break monitoring setting

- The robot setting (how the robot should react to the "Ignore" setting on the arc break

monitoring)

For the "Ignore" setting:

- The robot sets the Welding start signal to Low (= no reignition of the arc), or

- Leaves the Welding start signal on High (= reignition of the arc) – depending on the

robot setting

For the "Error" setting:

- An error message is output and the welding process is stopped

47

EN-US

Loading...

Loading...