80209C_MHW_850-1650-1850_20-2020_ENG_pag. 18

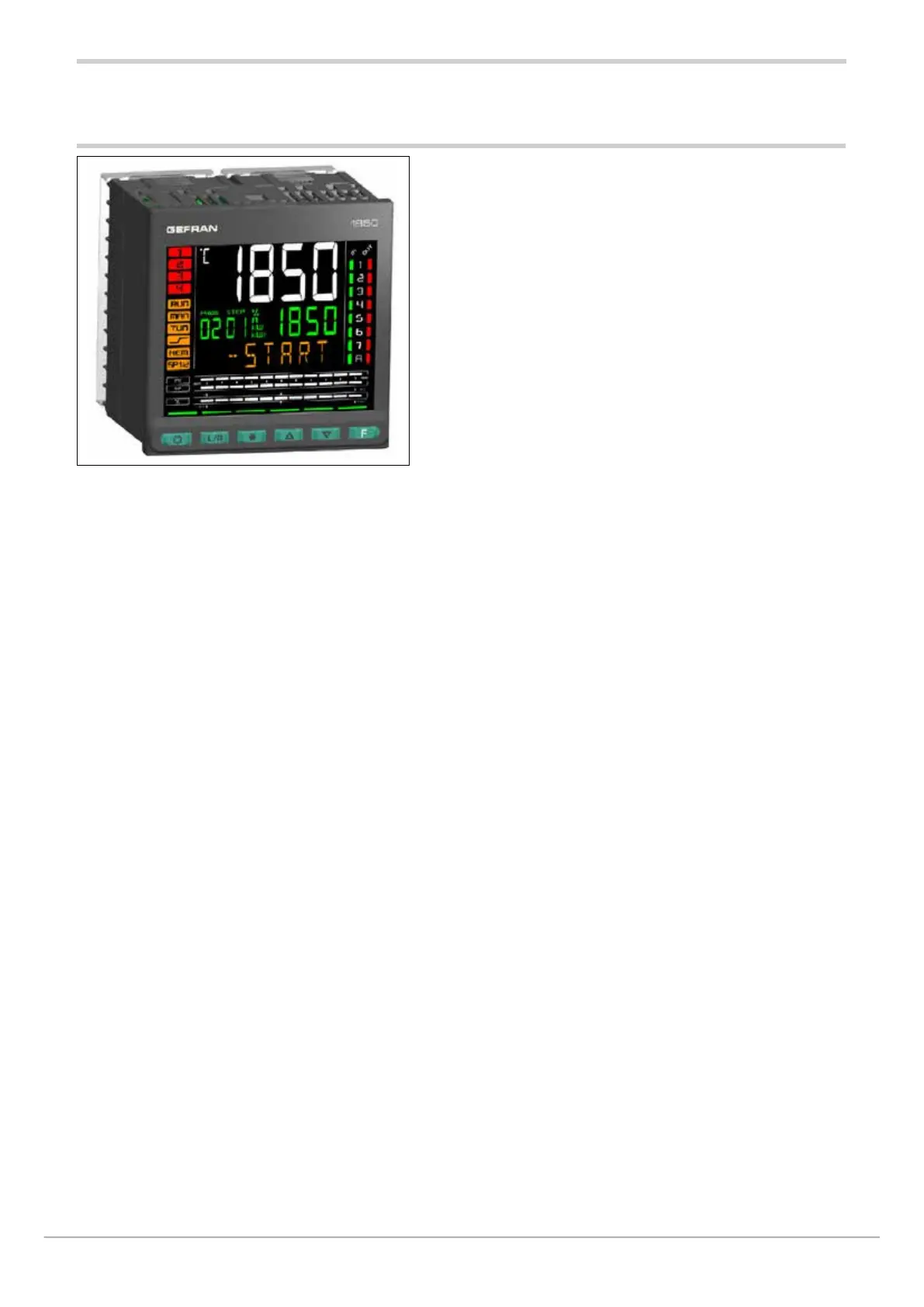

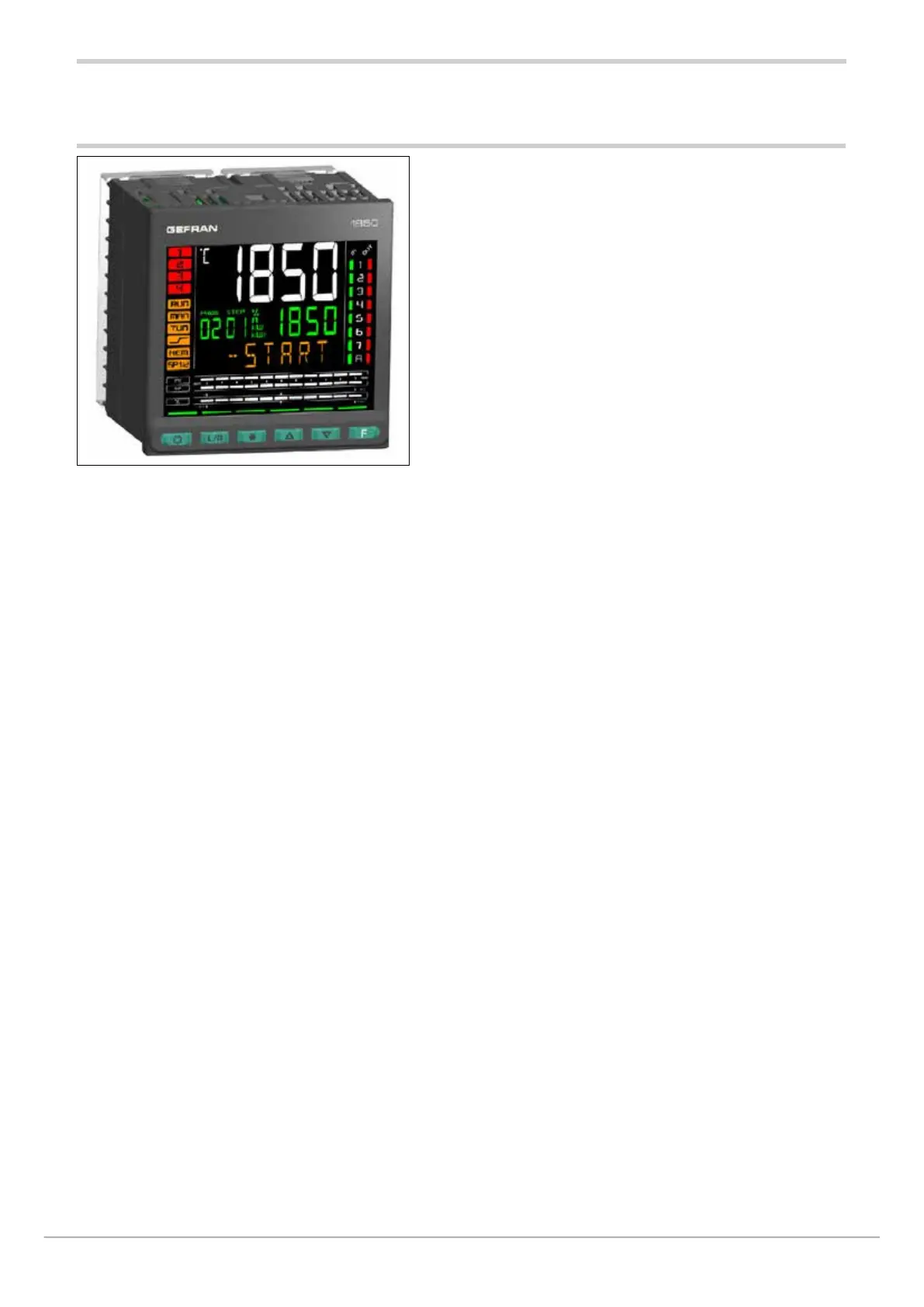

1.5. 1850 Controller

Main features

•

Operator interface with large LCD Display and three configurable

bargraphs

• Scrolling diagnostics messages, configurable, in the selected language

• Easy, guided configuration, copy/paste parameters even with power off

• Preventive maintenance with energy counters (kWh) and load switching

• 32 function block applications

• 8 Math application blocks

• Timer, setpoint and algorithm programmer for controlling motorized

valves

• Advanced tuning of control parameters

• Different password levels

• 2 configurable universal inputs for Thermocouples, Resistance

Thermometers, Linear inputs

• 1 linear analogue input configurable for auxiliary functions

•

2 PID control loops

• 2 setpoint programmers (192 steps in 16 programs, or 12 programs

with 16 fixed steps each)

•

Relay, logic, isolated analog outputs

• Up to two TA inputs for interrupted load diagnostics

• RS485 serial communication in Modbus RTU slave

• RS485 serial communication in Modbus RTU master for reading/

writing information to Modbus slave devices• Ethernet Modbus

TCP communication in Slave mode

• Web server for browser access to web pages residing in the device,

for monitoring and setting parameters

• Bridge function for creation of Modbus RTU 485 sub-network

• Weekly clock\calendar with RTC

•

Removable faceplate for immediate replacement

• Accuracy 0,1%, sampling time 60 ms

Dimensions 96 × 96 × 80 mm (1/4 DIN)

Loading...

Loading...