After filter pressure monitoring MagicControl 4.0 (CM40)

Typical characteristics

– Filter monitoring (pressure switch) with two channels

– The following volume flows or fan Δp with two pressure switches

each are monitored:

• Volume flow operating point

• Volume flow alarm

• Volume flow ATEX: Stop powder

– Two additional differential pressure monitors transmit the pressure of

the filter system to the CM40.

– There are no more pressure gages in or on the cabinet. Everything

is displayed on the MagicControl CM40 screen.

– Only a main power supply is required as a power supply:

• The ICS filter cabinet contains a fuse to protect the power supply

– Cartridge cleaning is no longer time-controlled, but pressure-

controlled:

▪ As soon as the cartridge resistance exceeds a pre-set value, the

cleaning sequence begins, with all filter cartridges being cleaned

at least every hour.

– Two different control cabinet types:

▪ Star-delta control version: OptiControl ICS08

▪ FC operation version: OptiControl ICS09

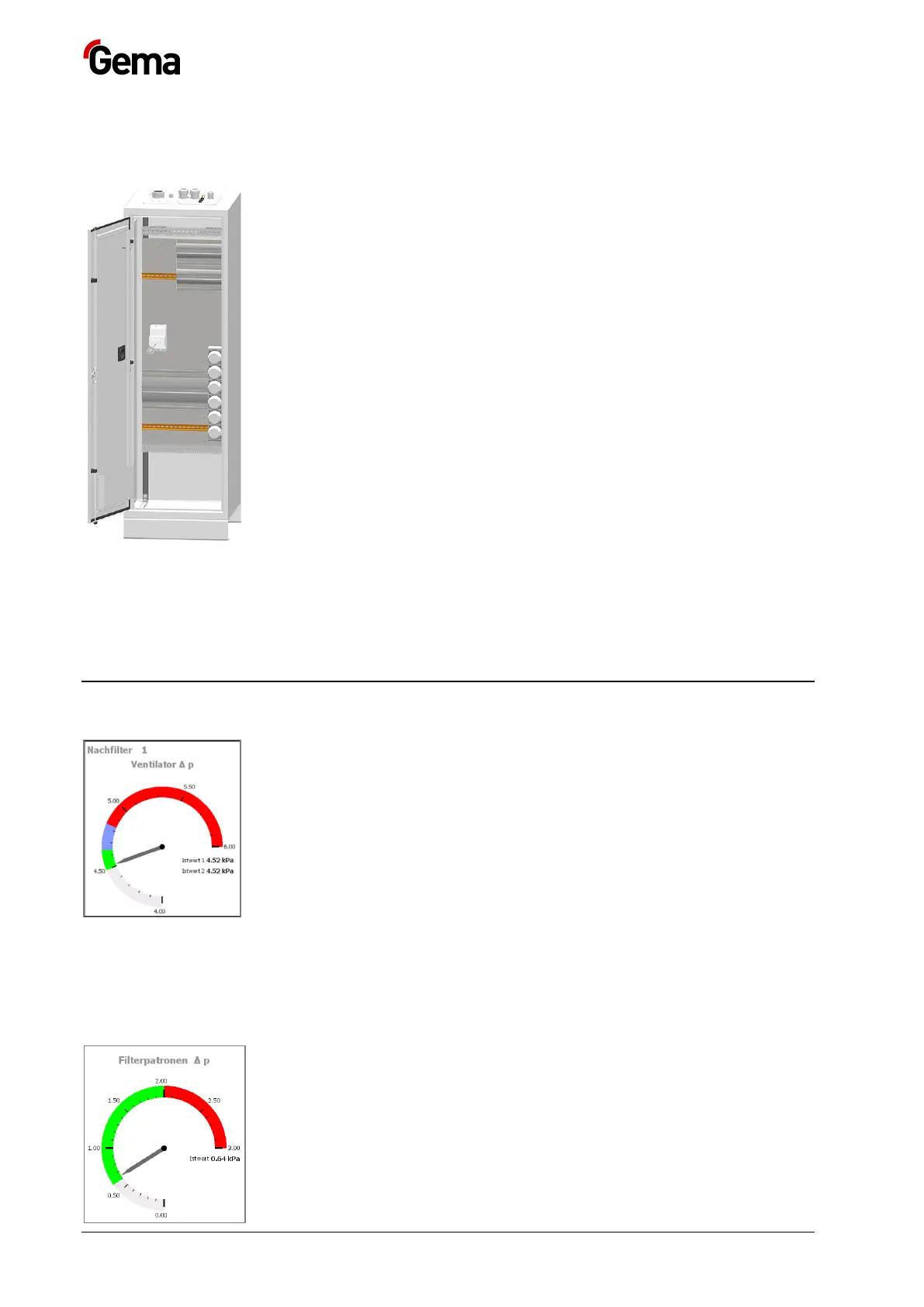

Description of the pressure switches

315 B1 differential pressure monitor Fan Δp

– The differential pressure monitor measures the current differential

pressure of the fan.

– The pressure is displayed on the CM40 control unit at Fan Δp:

Actual value 1.

– The pressure display at Fan Δp shows this value.

315 B3 differential pressure monitor Fan Δp

– The differential pressure monitor measures the current differential

pressure of the fan.

– The pressure is displayed on the CM40 control unit at Fan Δp:

Actual value 2

316 B1 differential pressure monitor Filter cartridges Δp

– The differential pressure monitor measures the actual differential

pressure of the filter cartridges (filter resistance).

– The pressure is displayed on the CM40 control at Filter cartridges

Δp: Actual value.

Loading...

Loading...