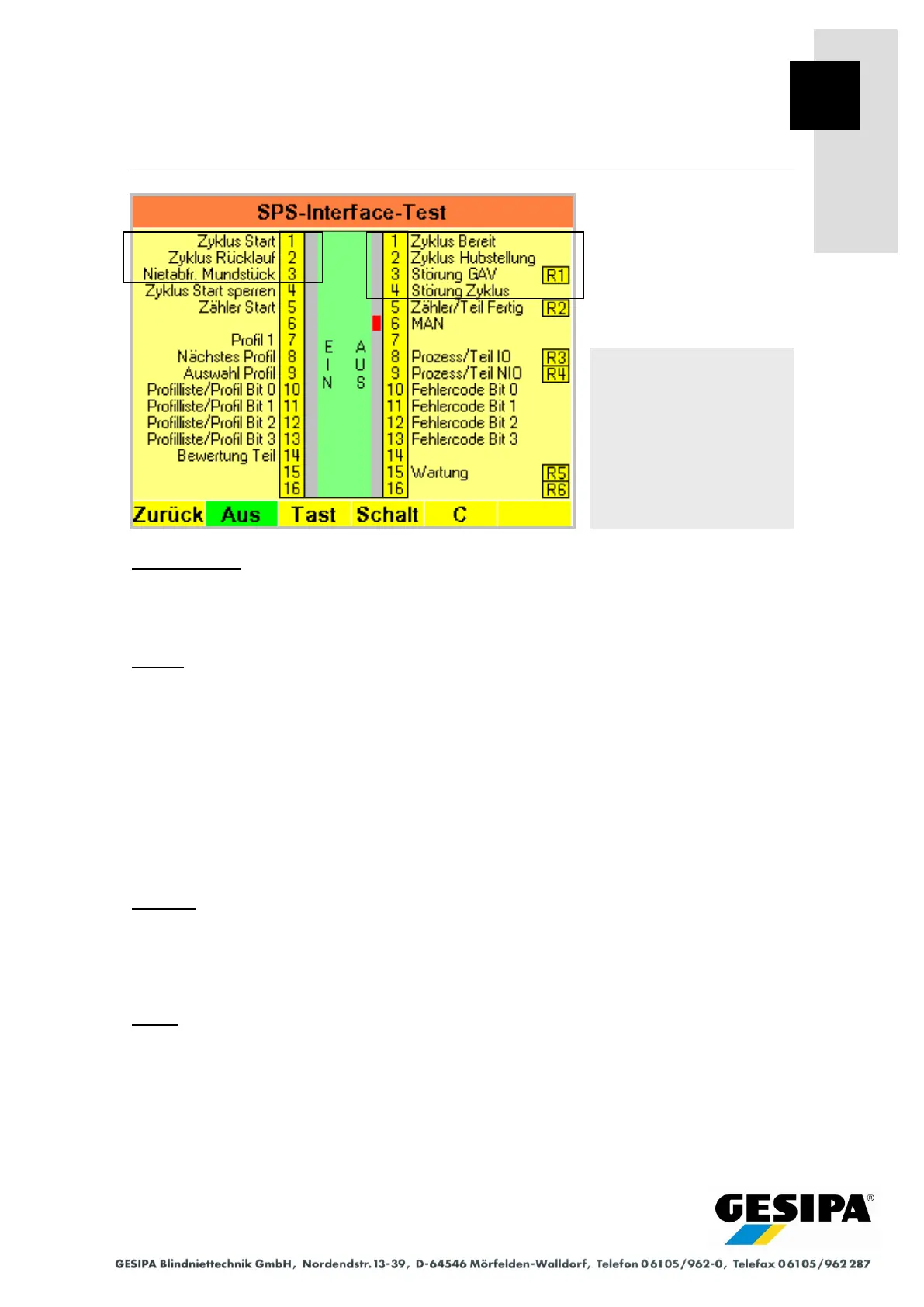

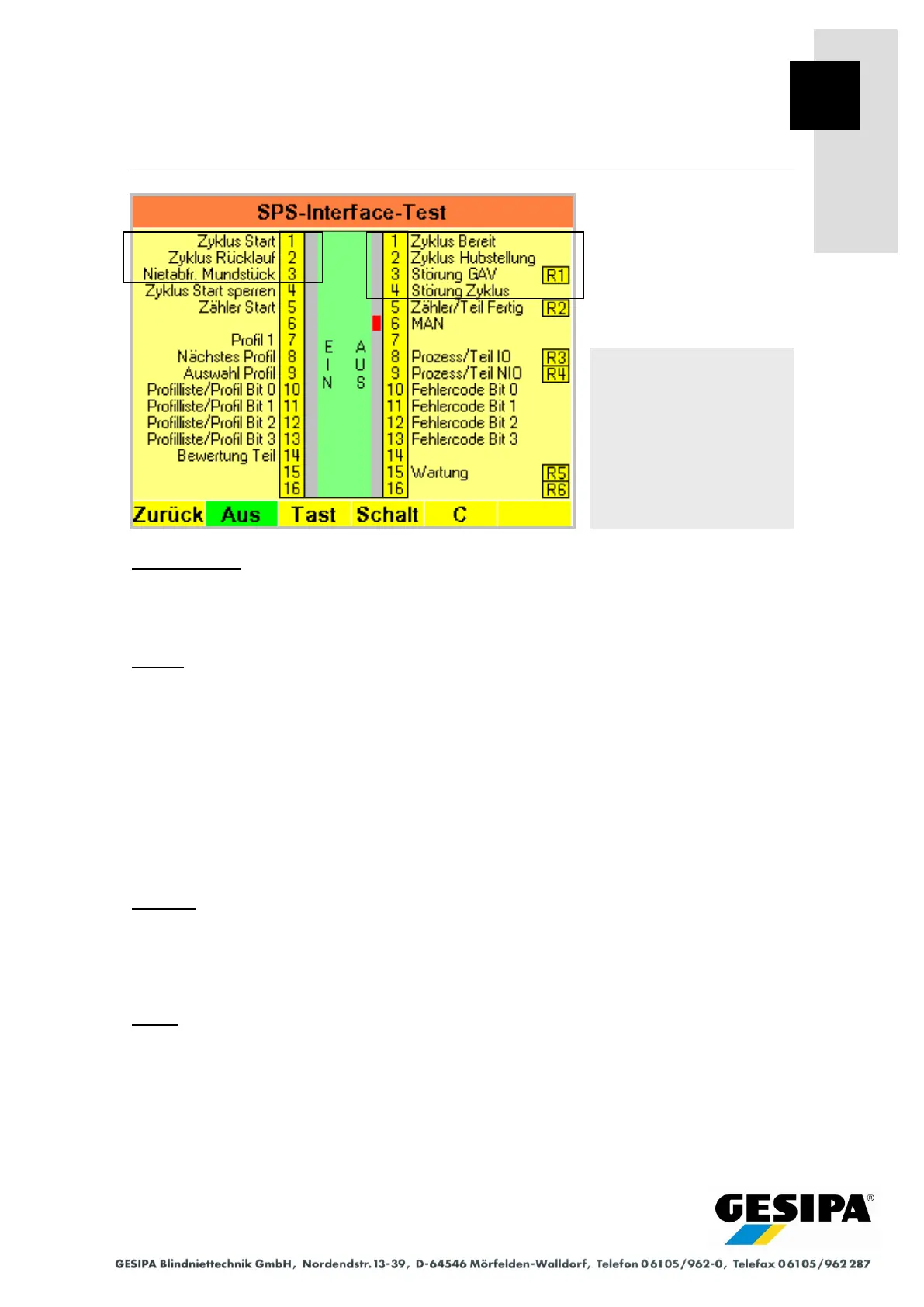

PLC Interface

28.3 PLC Activation

Preconditions:

● PLC interface connected to GAV.

● PLC connected to PLC interface.

● PLC activation active: AUTO►MAN►Menu►GAV Settings►PLC Activation.

Inputs:

Input 1 "Start Cycle" Cycle up to stroke position (process blind rivet).

Input 2 "Return Cycle" Return cycle (load new blind rivet).

Input 3 "Rivet Check, Nosepiece" Sensor for monitoring loading procedure.

Input 3 "Rivet Check, Nosepiece" is used for operating the GAV in a fully automatic blind rivet-

ing system. A suitable sensor (24 VDC N/O contact, e.g. light barrier) must be installed in the

blind riveting system such that a blind rivet loaded in the spreader nosepiece is detected with

the blind riveting system in home position. The sensor signal is evaluated by the GAV controller

during the loading procedure and, if necessary, sent to output 3 as "GAV Fault". This function is

optional and must be activated during setup in

AUTO►MAN►Menu►GAV Settings►PLC Activation

Outputs:

Output 1 "Cycle Ready" GAV in home position, no fault.

Output 2 "Cycle, Stroke Position" Cycle, stroke position reached, spent mandrel evacuated.

Output 3 "GAV Fault" GAV fault.

Output 4 "Cycle Fault" Cycle stopped due to fault.

Relay:

Relay R1 is switched when output 3 "GAV Fault" is 1 (24 V).

Navigation:

AUTO

►MAN

► Menu

► GAV settings

► PLC interface test

Loading...

Loading...