PLC Interface

28.3 PLC Activation

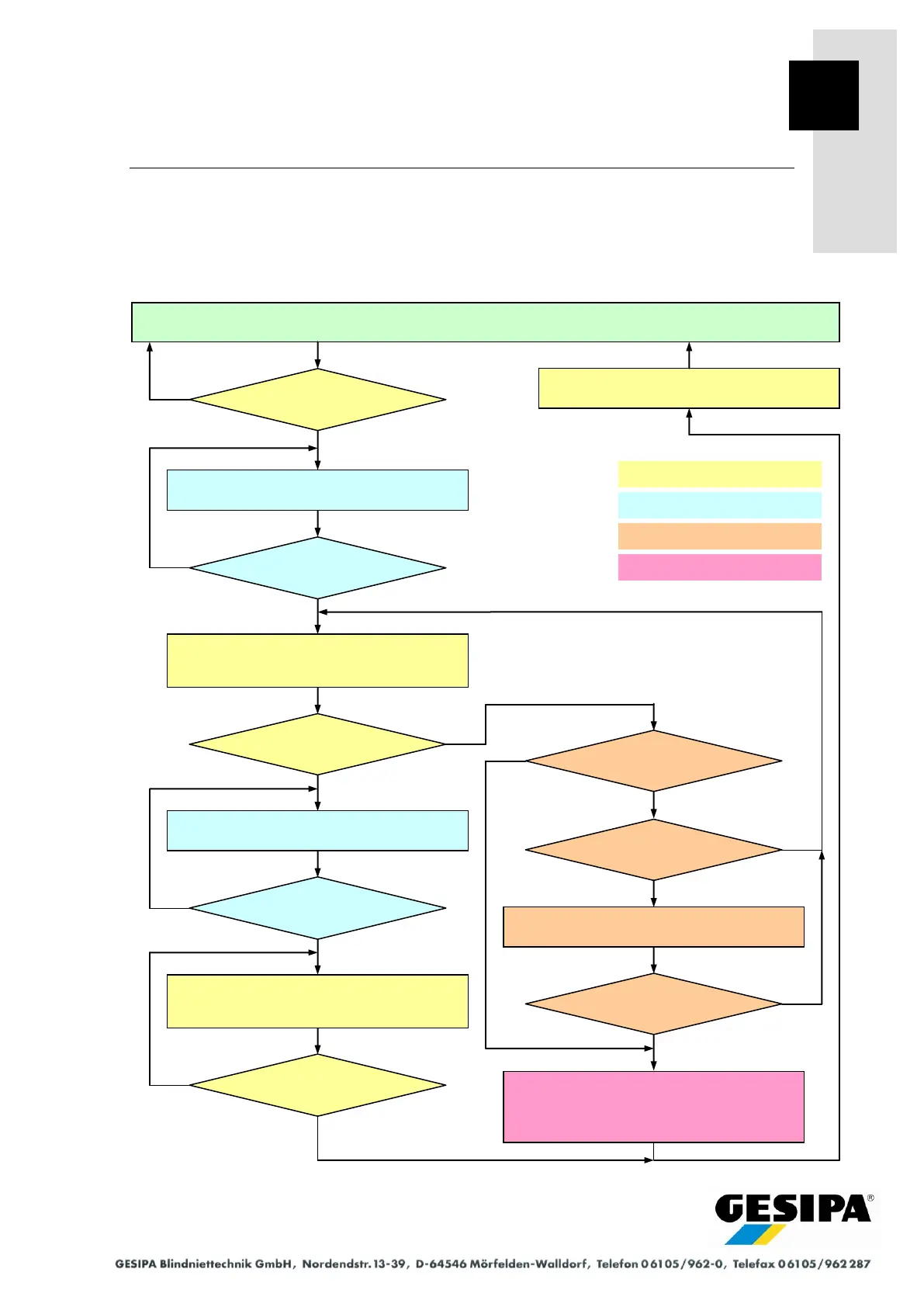

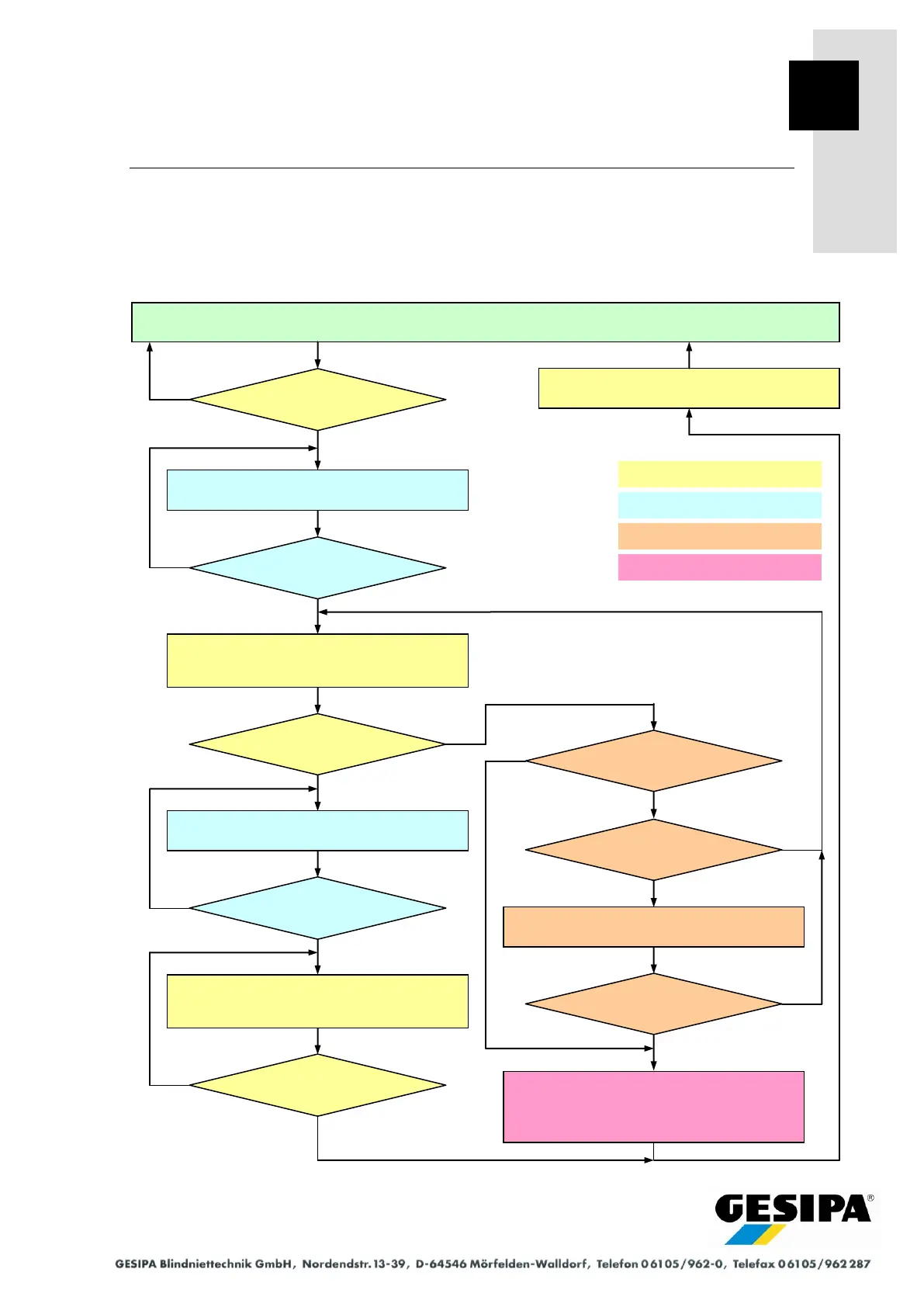

The flowchart shows the typical communication of a GAV8000 with the PLC of a device via the

PLC interface. Here for example, the GAV riveting gun is mounted on the transport slide of a

device such that it can move axially, the slide can reach its end position in two positions, at a

distance of approx. 50 mm from the workpiece and the blind rivet is inserted in the workpiece.

For maintenance and troubleshooting, the transport slide should additionally feature a free-

moving option so that the nosepiece area and mandrel ejection are well accessible.

Transport slide in

working position?

Move transport slide of device to working position

(insert blind rivet in workpiece)

Start cycle Input 1 ► 1

Return cycle Input 2 ► 0

(process blind rivet)

Cycle, stroke position

Output 2 = 1?

Move transport slide of device in starting position

(approx. 50 mm from workpiece)

Transport slide in

starting position?

Cycle ready

Output 1 = 1?

Start cycle Input 1 ► 0

Return cycle Input 2 ► 1

(load new blind rivet)

Start cycle Input 1 ► 0

Return cycle Input 2 ► 0

Device and GAV in home position

Transport slide of device in starting position (approx. 50 mm from workpiece)

Cycle ready

Output 1 = 1?

Cycle fault

Output 4 = 1?

Start cycle Input 1 ► 0

Return cycle Input 2 ► 0

2. Cycle faults

one after the other?

STOP!

- Manual fault correction

- Manual free-moving option of transport slide of

device

Transport slide of device

Loading...

Loading...