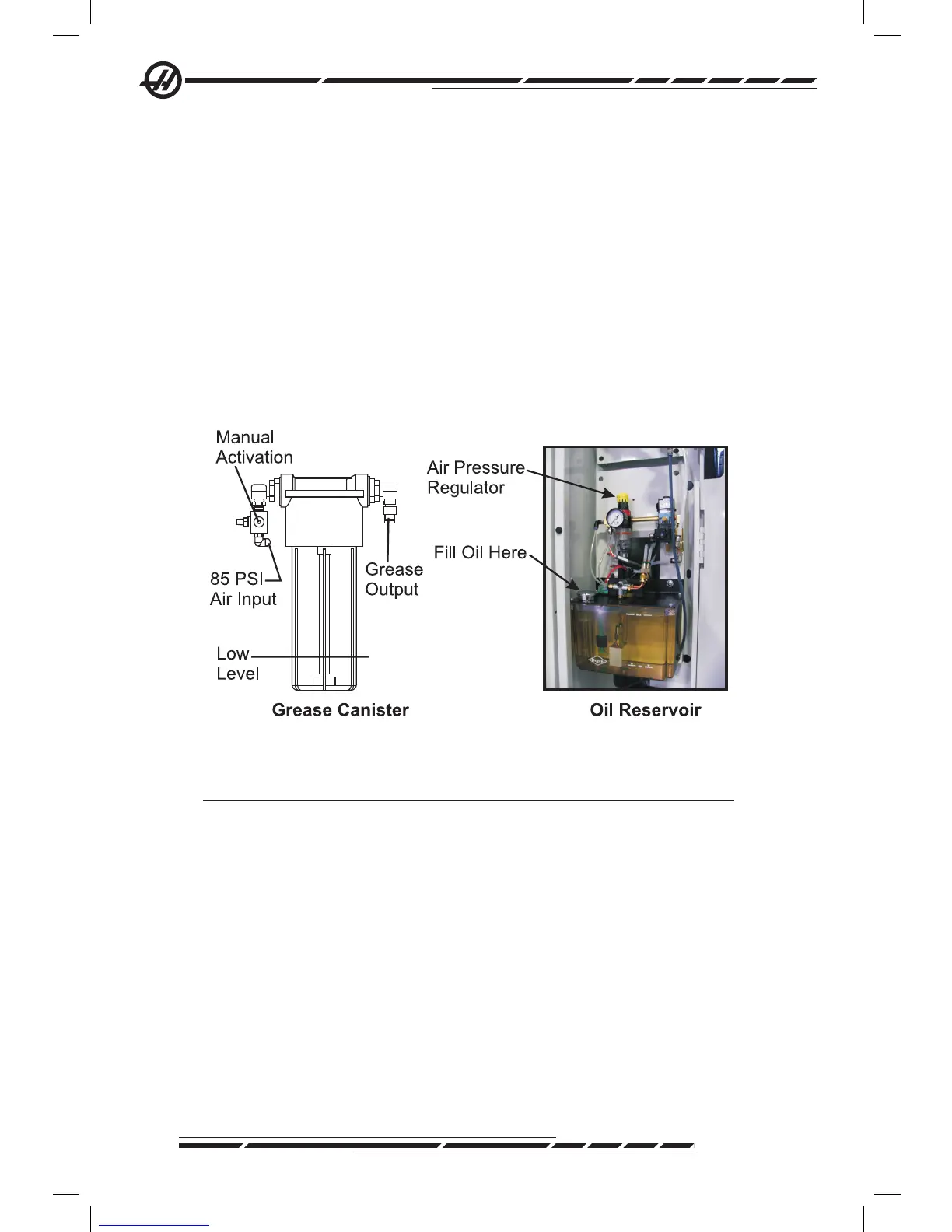

The grease system injects lubrication based on the distance of axis travel

instead of time. Grease is injected once any of the axes has traveled the dis-

tance dened in parameter 811. This grease is distributed equally to each of

the lubrication points for all axes.

A full grease canister should last approximately one year.

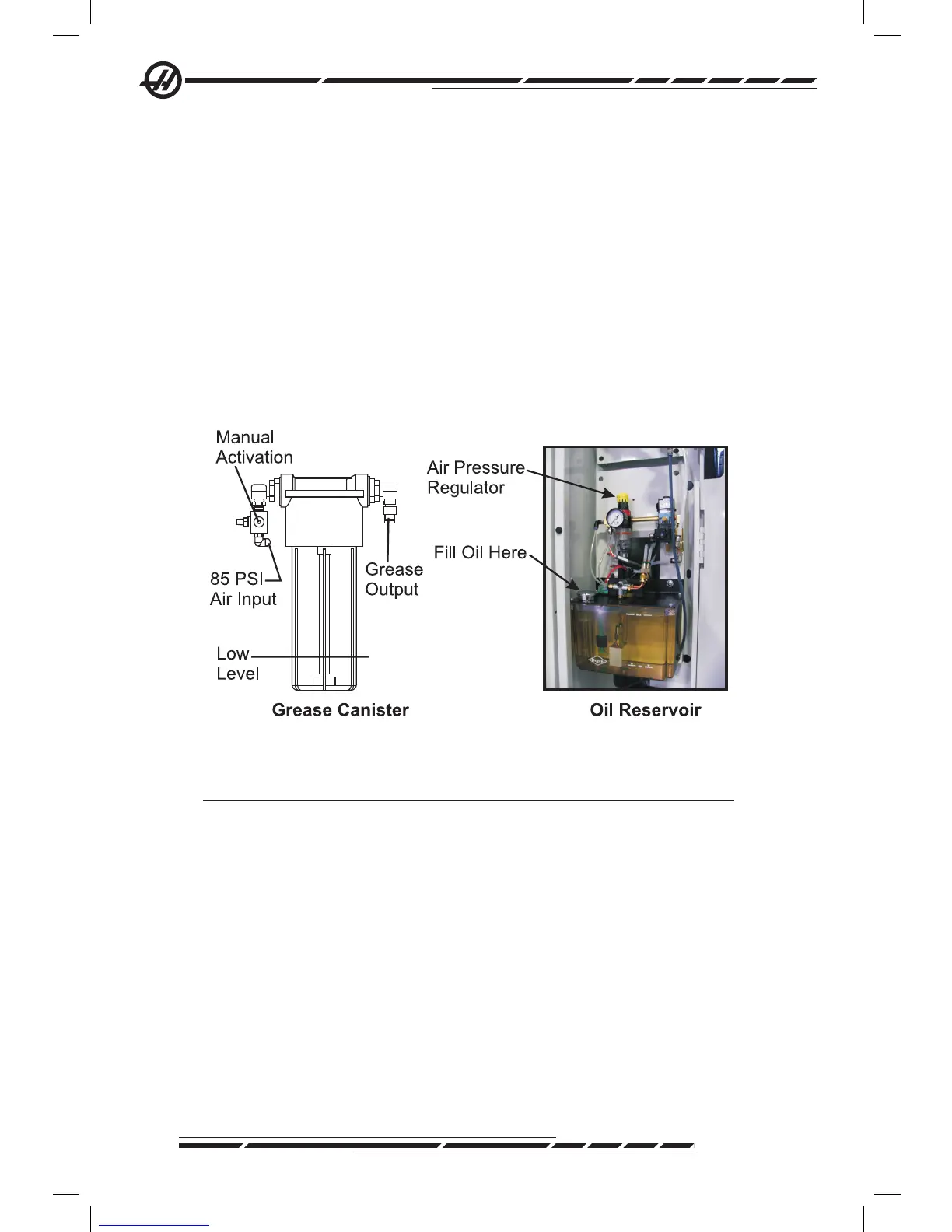

Air/Oil System - The minimal lubrication system for the spindle is an air/oil

mixture. The air/oil system injects lubrication based on the number of actual

revolutions of the spindle. A timed air/oil injection cycle is also used for low

speed spindle operation to ensure an adequate amount of lubrication to the

spindle.

A single tank of oil should last a minimum of 1 year of continuous spindle op-

eration.

.

Maintenance

Grease Canister Rell:

Note: Make sure to check the grease level regularly. If the reservoir

becomes completely empty, do not rell the reservoir and do not operate

the machine. Contact your dealer to have the system purged and primed

before you operate the machine.

Use one of the following Mobile Grade 0 greases to rell the grease canister.

Mobilux EP0

XHP-220

You can also order a rell bag using Haas part number 93-1293.

1. Disconnect machine air.

2. Use the provided wrench to loosen and remove the grease canis-

ter.

Loading...

Loading...