3.

Attach the jig to the planer fence.

4.

Place the protective guard all the way down and let it rest against the jig.

5.

Additional procedures as described in the chapter "Planing narrow edges".

⮫

Chapter 9.3.2 ‘Planing the narrow edge’ on page 60

9.4 Thickness planing

9.4.1 Working positions - thickness planing

CAUTION

Wedging of drive fed workpieces when thicknessing

Injuries and material damage. Insufficient distance to adjacent

machines, walls etc. can lead to wedging or splintering of the

workpieces.

− Ensure sufficient distance to neighbouring machines, to walls

or o

ther solid objects.

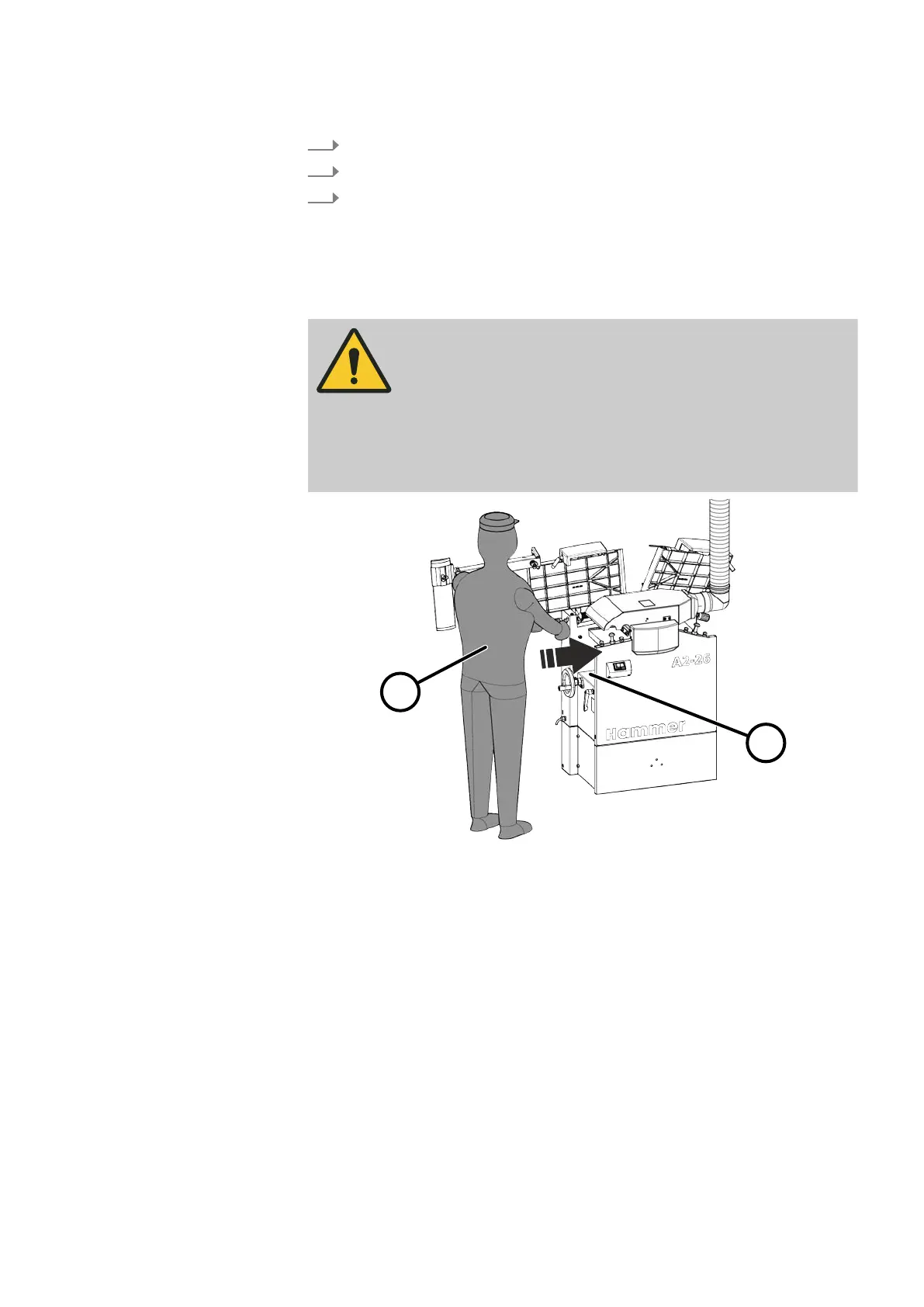

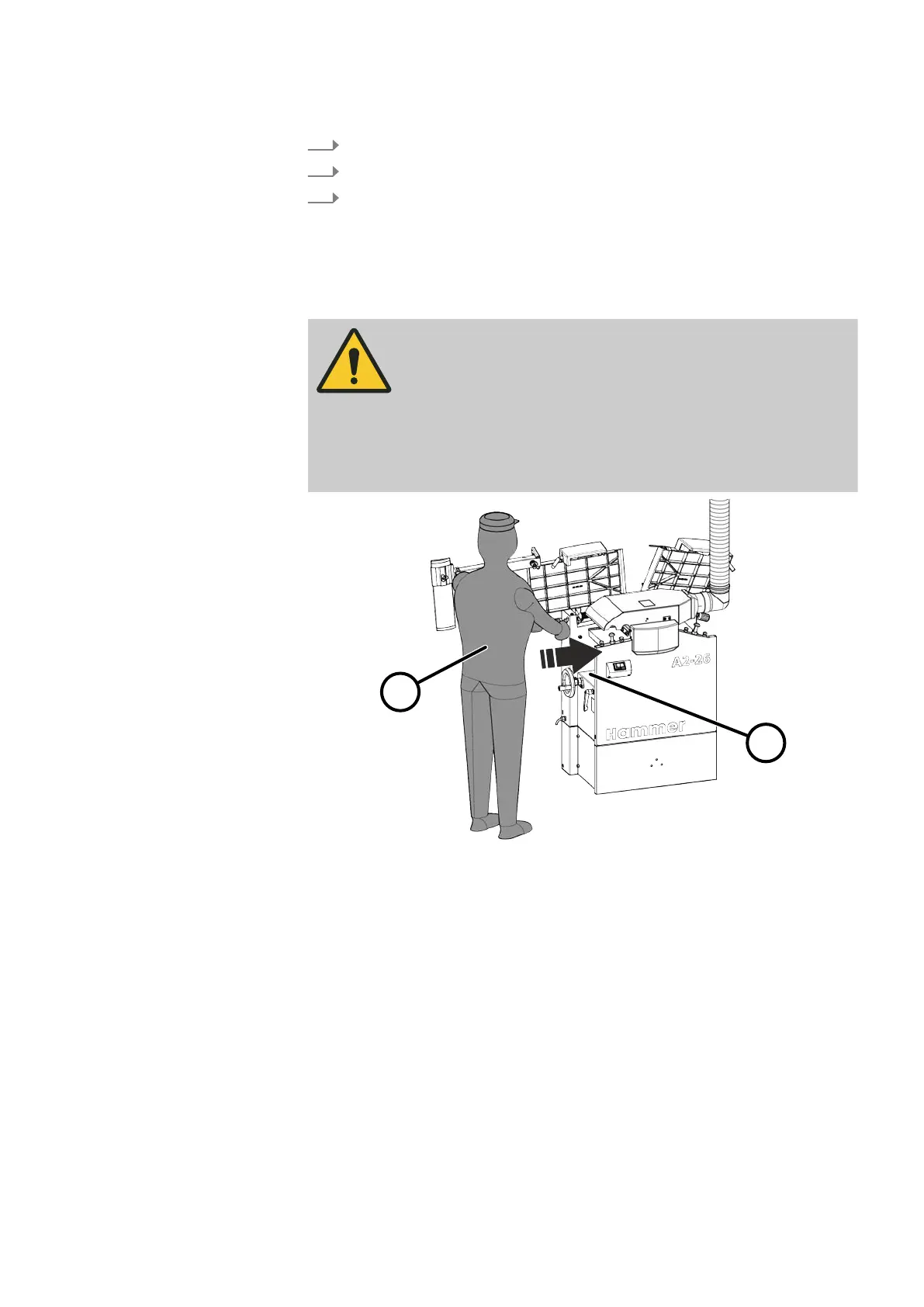

Fig. 49: Working position - thickness planing

1 Working position - thickness planing

2 Processing direction

9.4.2 Authorised thickness planing working methods

Dur

ing thickness planing, workpieces with an already planed surface are planed

thinner in parallel. Precise parallel thicknesses can only be obtained if the work-

piece was precisely surface-planed beforehand to ensure that it can lie flat on the

thicknesser table.

Only the following working techniques are permitted with the thickness unit,

depending on the configuration:

● Infeed roller - standard:

○ A maximum of 2 workpieces can be thickness-planed simultaneously.

Loading...

Loading...