10.5 Transport rollers and kickback guards

NOTICE

Damage to the workpieces due to improper maintenance

− Check the running surface of the in and outfeed rollers regu-

lar

ly for signs of wear and tear.

− If there are pressure marks in the planing pattern or poor feed,

c

lean the transport rollers immediately.

− Test the function of the kickback guard devices before each use

of the thic

knessing unit.

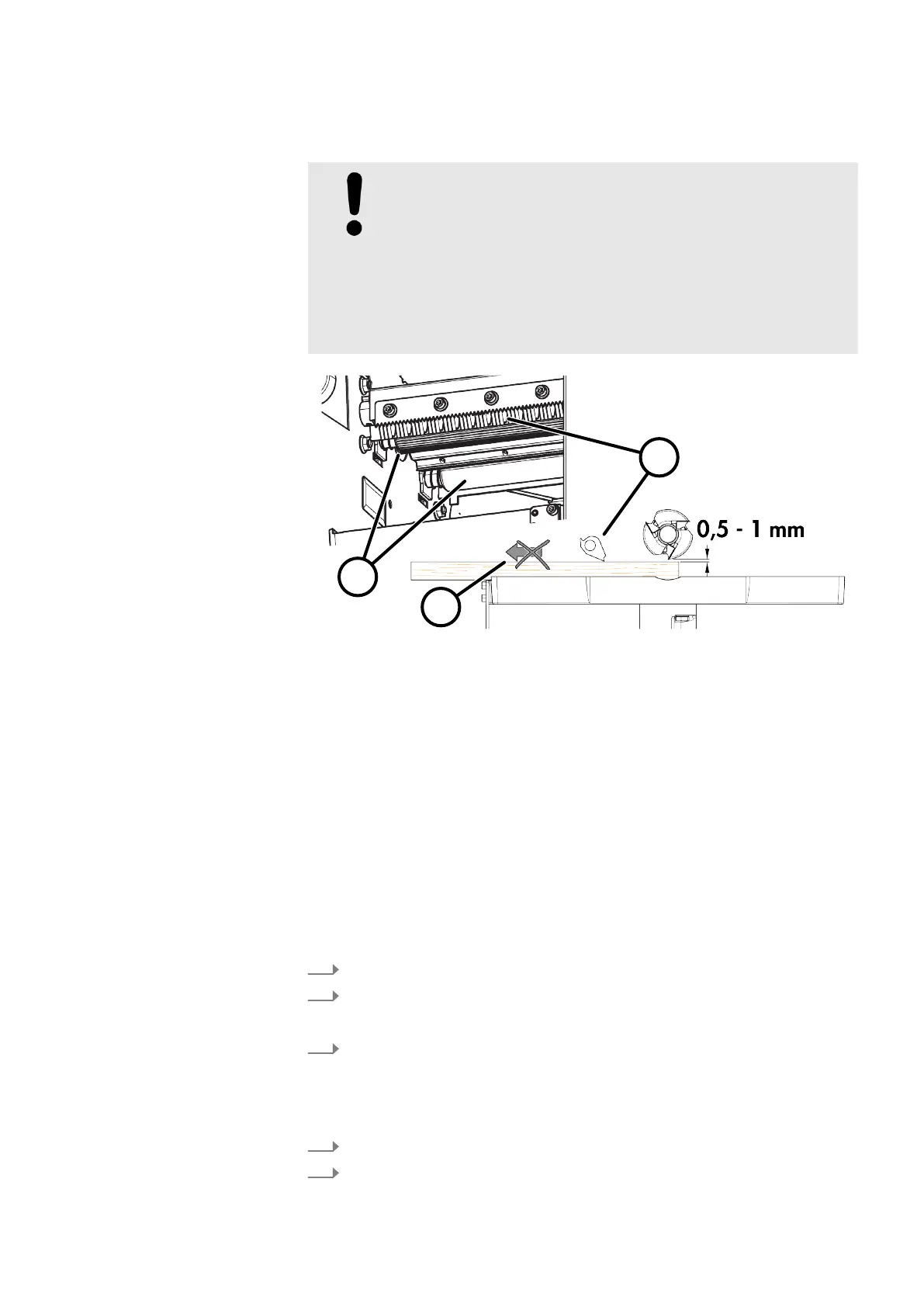

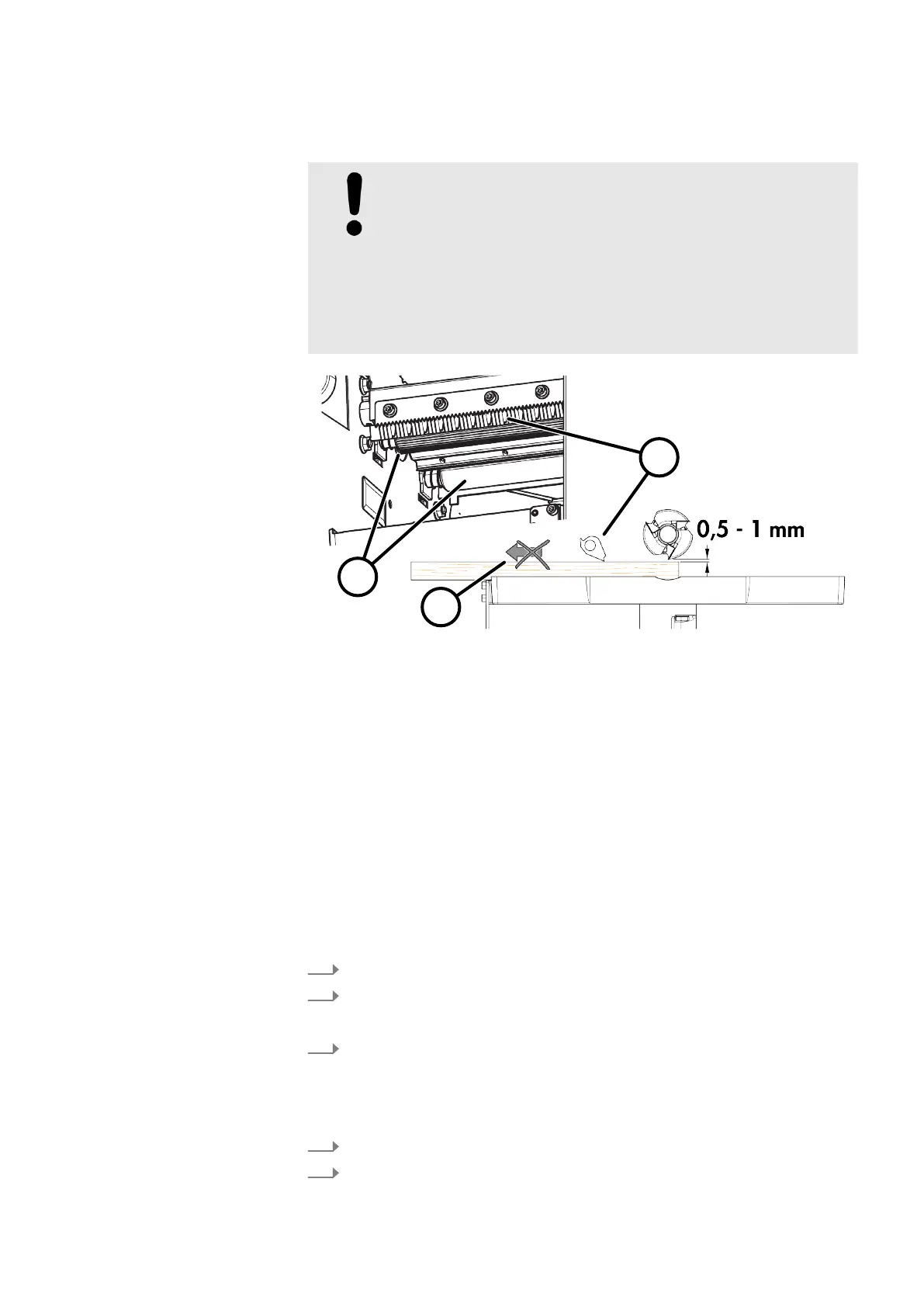

Fig. 54: Transport rollers and kickback guards

1 Feed rollers

2 Kickback guards

3 Planed panel

Check kickback guards/clean transport rollers

Pr

otective equipment:

● Protective clothing

● Protective gloves

● Safety goggles

T

ool:

● Cleaning cloths

● Resin remover

● Vacuum cleaner

1.

Clean the transport rollers monthly from resin residues.

2.

Check condition of kickback guards.

🡆

The kickback guards must not show any signs of damage.

3.

Test the function on a daily basis and remove traces of resin if necessary.

🡆

The individual kickback guards must fall back into place by themselves

af

ter having been lifted.

Testing the kickback guard function

1.

Switch off the machine and secure it against being switched on again.

2.

Push a planed board into the machine.

Loading...

Loading...