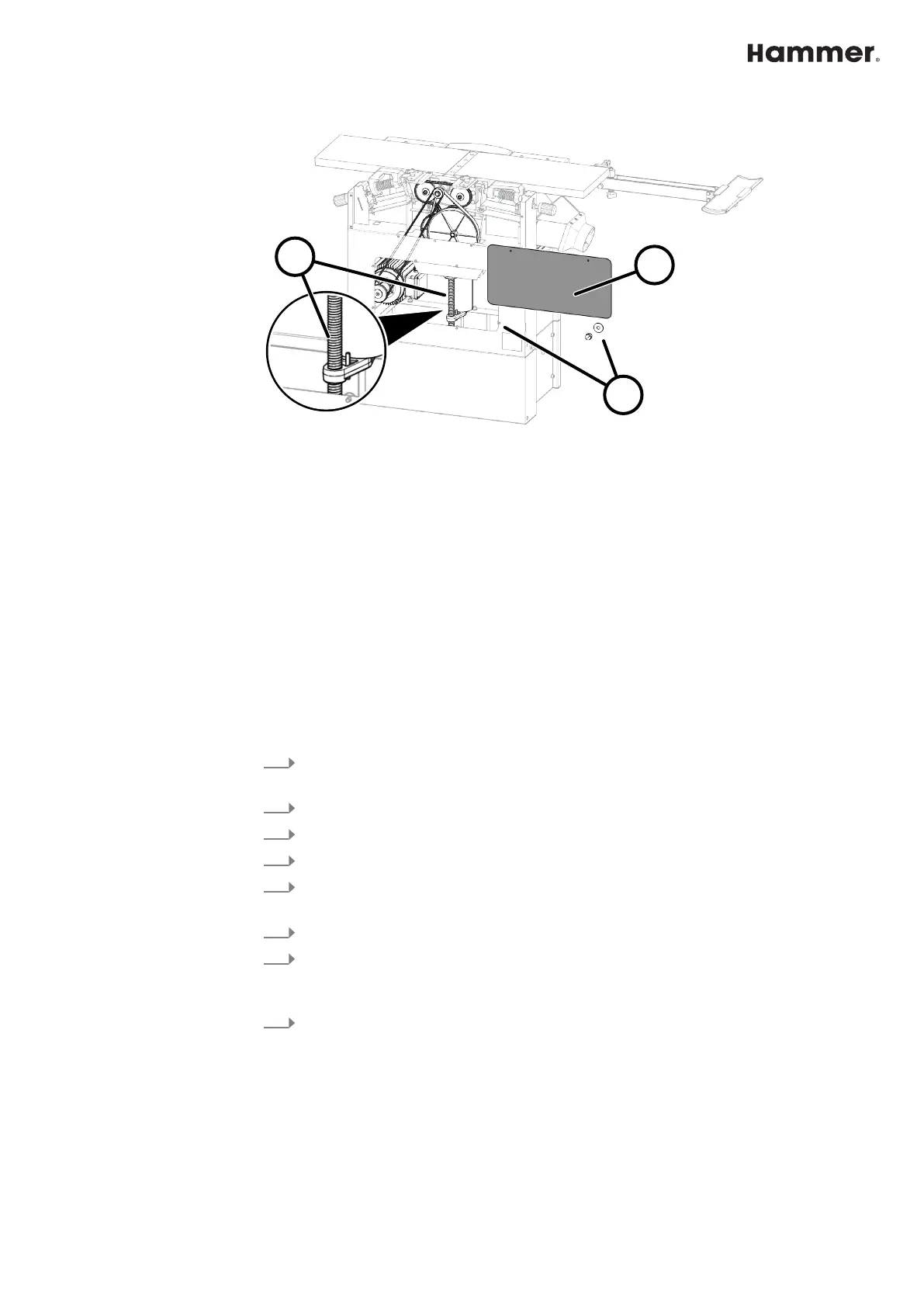

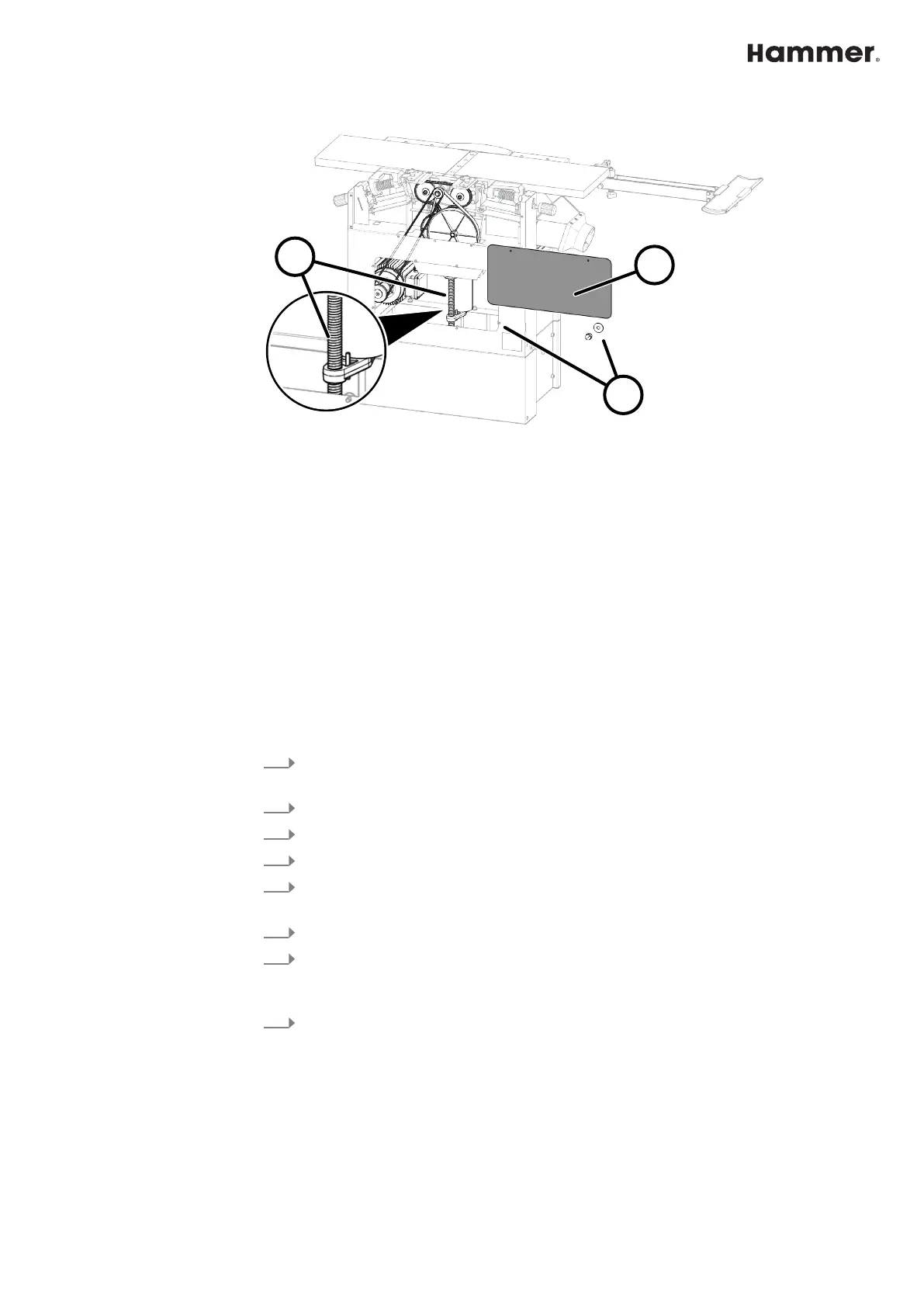

Fig. 57: Lubricating the height adjustment spindles

1 Nuts and washers

2 Cover lid

3 Thicknesser table height spindles

Protective equipment:

● Protective clothing

● Protective gloves

T

ool:

● Cleaning cloths

● Resin remover

● Vacuum cleaner

Ma

terial:

● Machine Grease

1.

Move the thicknesser table fully upwards. ⮫

Chapter 8.3.1 ‘Thicknesser

clearance height - general information’ on page 53

2.

Switch off the machine and secure it against being switched on again.

3.

Disconnect the machine from the mains power supply.

4.

Loosen and remove the nuts and washers (8x).

5.

Remove lid. ⮫

Chapter 10.4 ‘Preparation - Remove the maintenance cover’

on page 70

6.

Clean the spindles and then reapply machine grease lubrication.

7.

Move the thicknessing bed all the way down and then all the way back up

ag

ain. ⮫Chapter 8.3.1 ‘Thicknesser clearance height - general information’

on page 53

8.

Remount the cover. ⮫

Chapter 10.4 ‘Preparation - Remove the maintenance

cover’ on page 70

10.9 Check safety devices

Safety equipment must be checked every six months. The cutterblock with

clamped planing knives must be brought to a complete stop within 10 seconds. In

the event of any problems or malfunctions, please contact a member of the Felder

Group service centre.

Loading...

Loading...