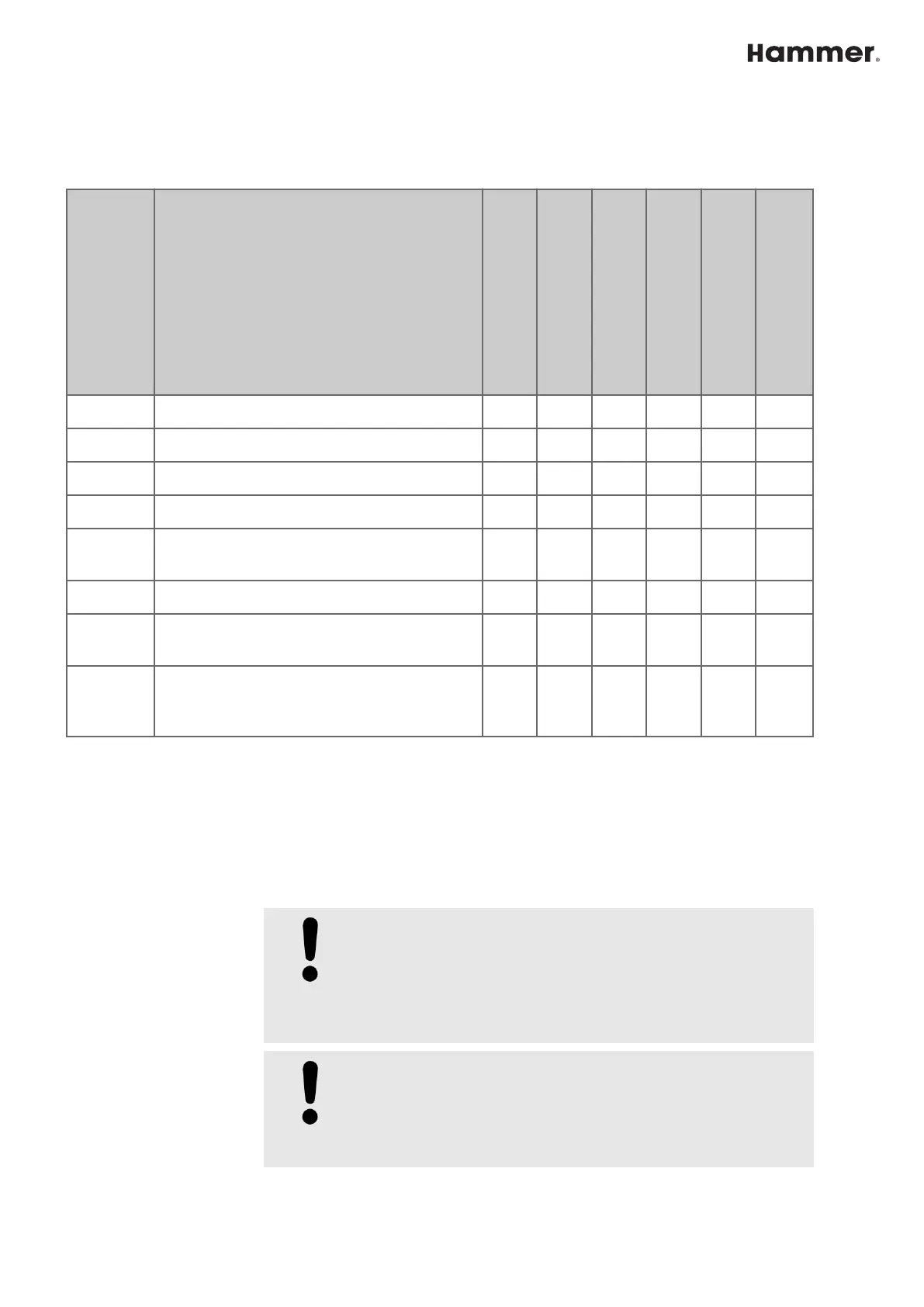

10.1 Maintenance schedule

T

he following maintenance work must be performed at the prescribed intervals.

Chap. Task to execute

10.3 Clean the machine X 69

10.5 Check kickback guards/clean transport rollers X X 71

10.6 Check belt tension and belt condition X 72

10.7 Drive chain feed rollers X X 73

10.8 Lubricate the thicknessing table height adjust-

ment s

pindles

X 73

10.9 Check safety devices X 74

10.9 Test the emergency stop if the machine is

eq

uipped with an [emergency stop] button

X 75

10.9 Test the red stop button as the emergency

s

top if the machine is not equipped with an

[emergency stop] button

X 75

10.2 Cleaning and lubricating

● Do not use compressed air to clean, as this will blow dust and shavings into

the v

arious ball bearings and guides.

● Only use low dust emission vacuum to remove dust deposits.

● Carry out cleaning when required, after each workday or at the very latest

af

ter 8 hours of operation.

NOTICE

Do not use graphite and MoS2 sprays

Guide tracks could be destroyed.

− Only use High Performance Grease (Art. Nr. 10.2.001) for

lubr

ication.

NOTICE

Caustic or abrasive cleaning detergents

Damag

e to the surface of the machine

− Never use caustic or abrasive cleaning detergents.

Loading...

Loading...