HIMax System 7 Diagnosis

HI 801 001 E Rev. 4.01 Page 89 of 122

7.2 Diagnostic History

Each HIMax module maintains a diagnostic history about the occurred faults or other

events. The events in the history are stored in chronological order. The history is organized

as a ring buffer.

The diagnostic history is composed of short term diagnosis and long term diagnosis.

Short term diagnosis

If the maximum number of entries has been reached, each new entry deletes the oldest

entry.

Long term diagnosis

The long term diagnosis essentially stores actions and configuration changes performed

by the user.

If the maximum number of entries has been reached, each new entry deletes the oldest

entry if this is older than three days.

The new entry is rejected if the existing entries are not older than three days. The

rejection is marked by a special entry.

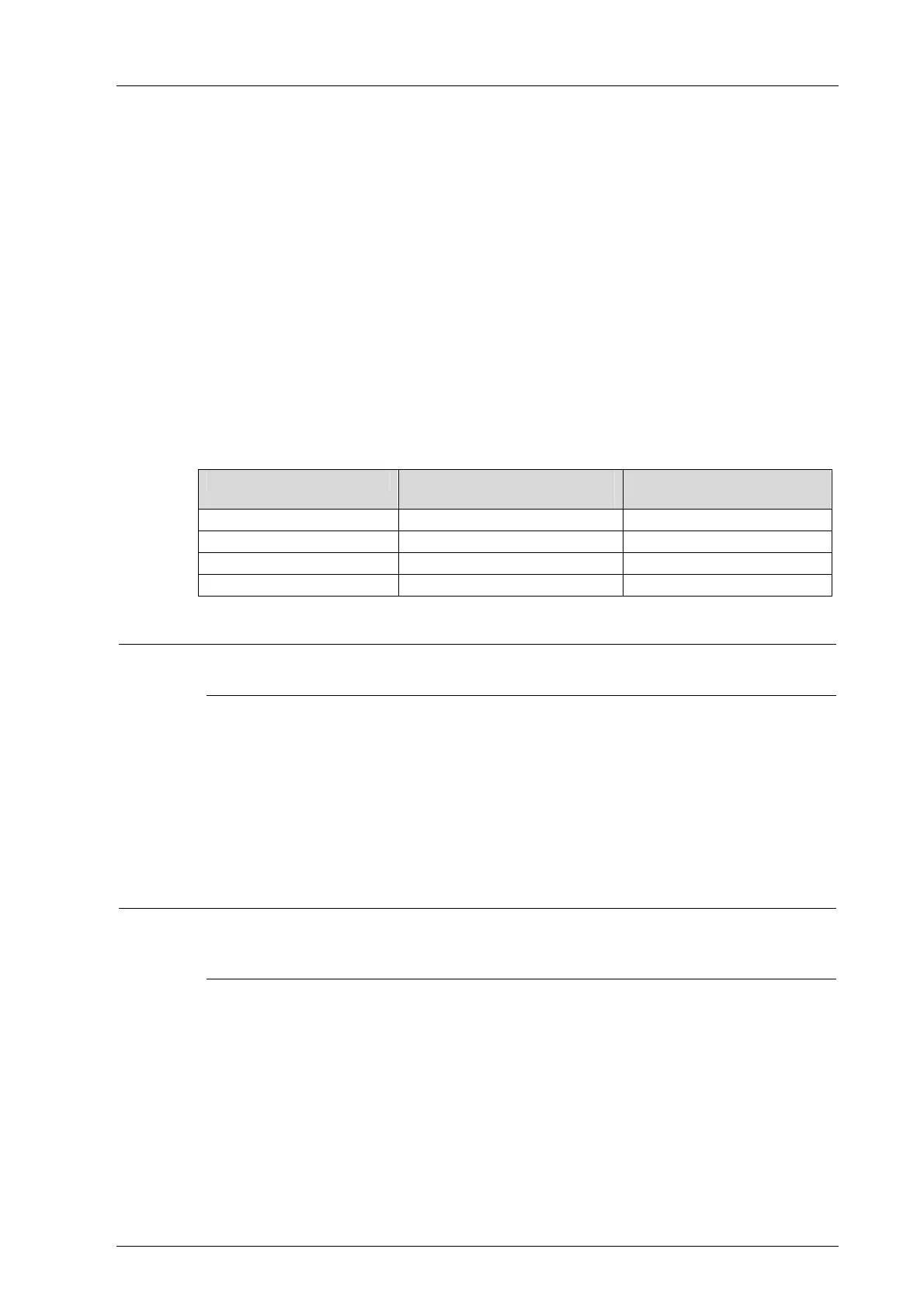

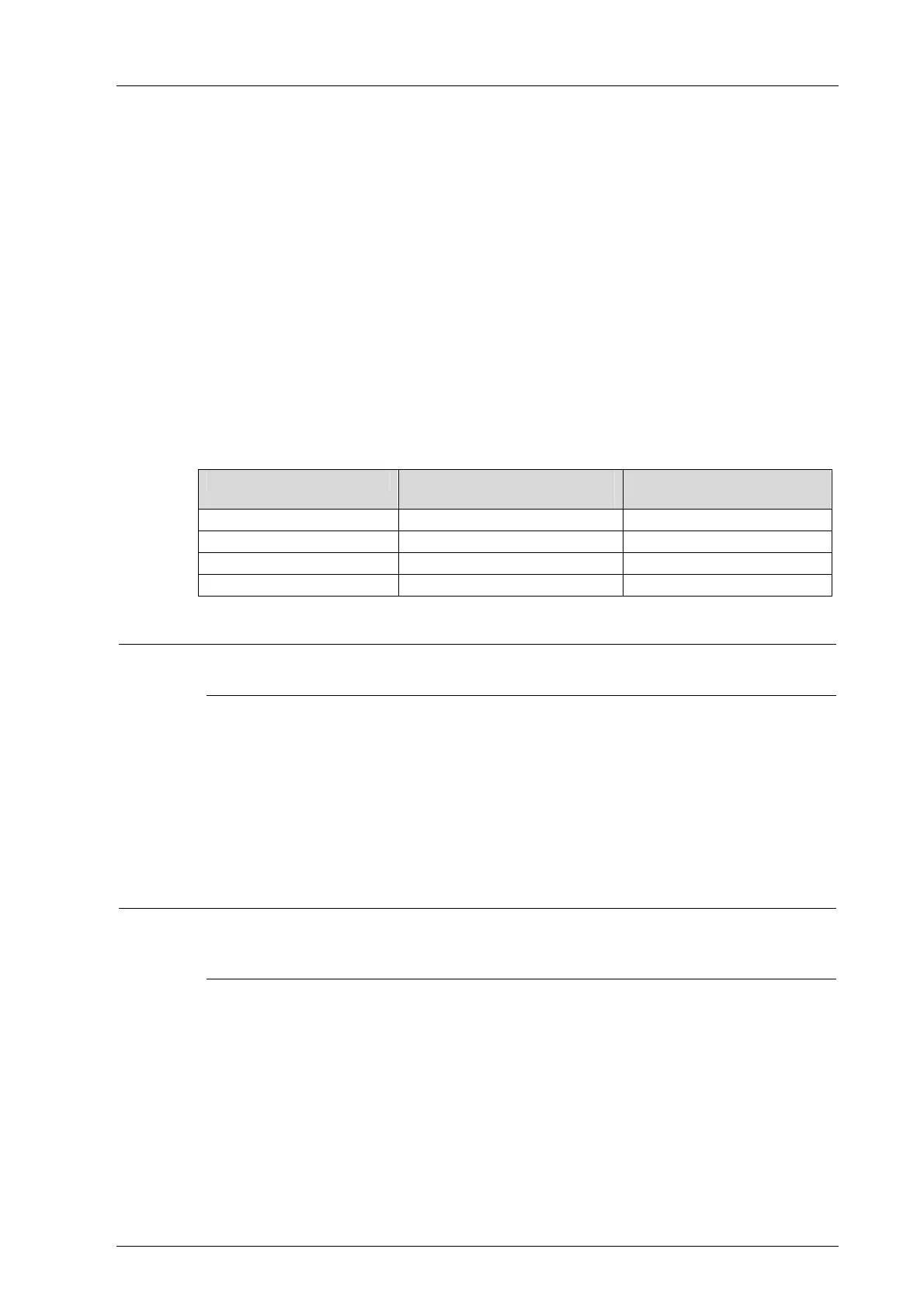

The number of events that can be stored depends on the type of module.

Module Type

Max. number of events

long term diagnosis

Max. number of events

short term diagnosis

X-CPU 01 2500 1500

X-COM 01 300 700

I/O modules 400 500

X-SB 01 400 500

Table 41: Maximum Number of Entries Stored in the Diagnostic History per Module Type

i

The diagnostic entries can be lost if a power outage occurs just before they could be saved

into non-volatile memory.

SILworX can be used to read the histories of the individual modules and represent them so

that the information required to analyze a problem is available. Example:

Mixing the histories from various sources

Filtering them according to the time period

Printing out the edited history

Saving the edited history

For additional functions, see the SILworX online help.

i

If a module is plugged in to a base plate, it generates diagnostic messages during its

initialization phase indicating faults such as incorrect voltage values.

These messages only indicate a module fault if they occur after the system starts operation.

7.3 Online Diagnosis

The Online View in the SILworX Hardware Editor is used to diagnose failures in the HIMax

modules. Failed modules are signalized by a color change:

Red indicates severe failures, e.g., that the module is not inserted.

Yellow indicates less severe failures, e.g., that the temperature threshold has been

exceeded.

Point to a module to display a tooltip providing the following state information about the

module:

Loading...

Loading...