127

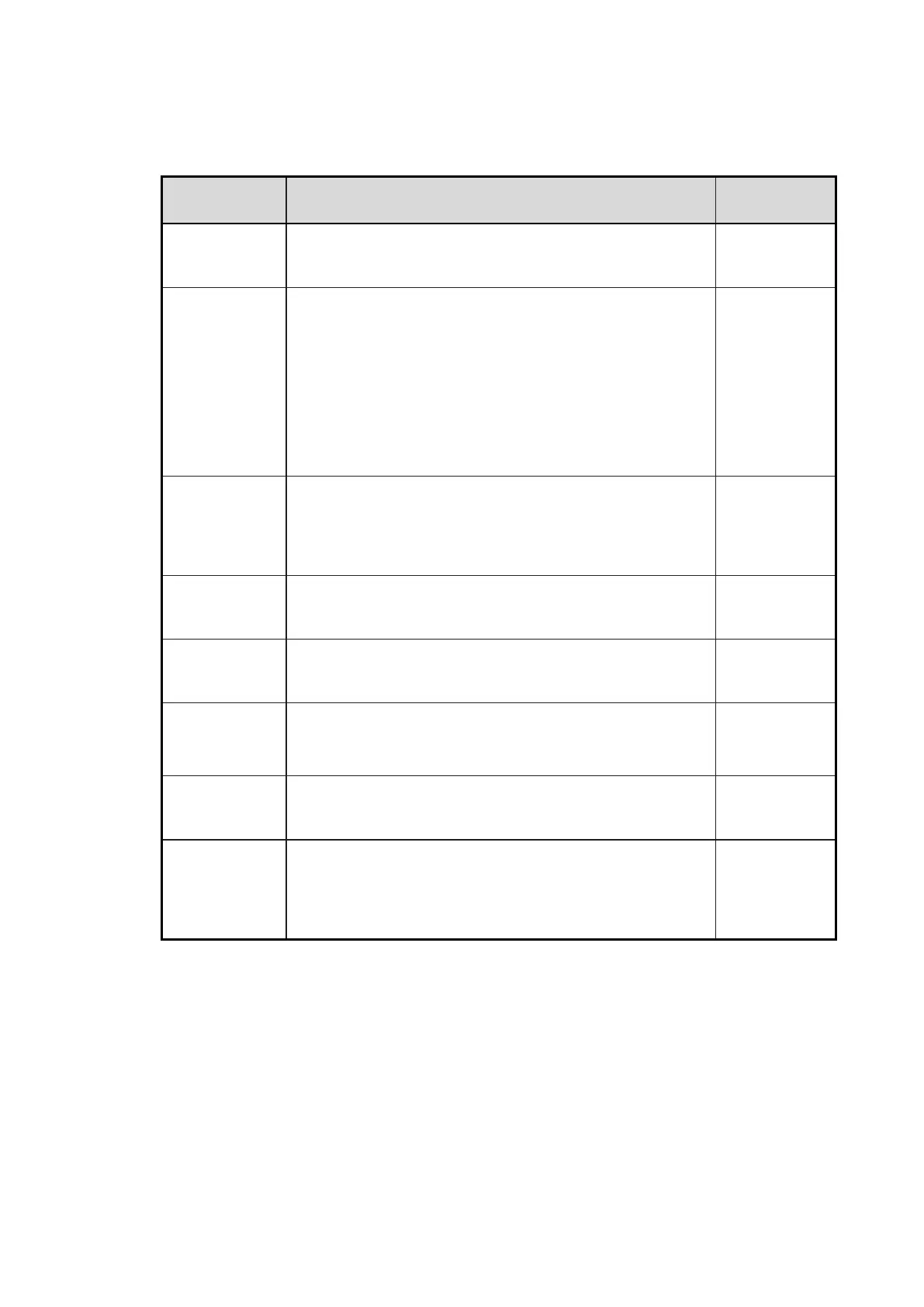

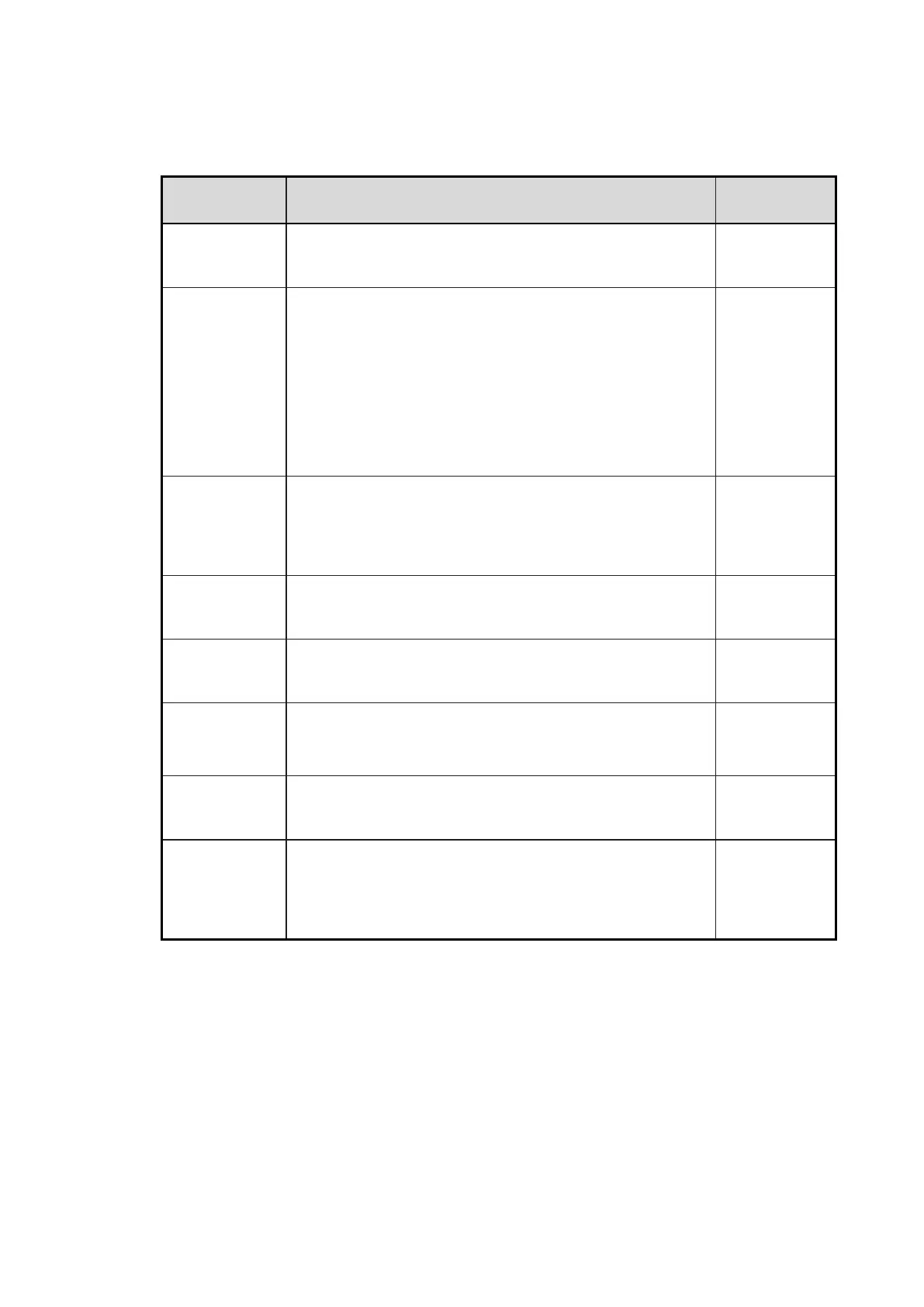

6.3.2. Details of Safe-Clean Station Function

Cleans the print head using the Safe-Clean Station.

For the operation procedure, see "11.2. Head Cleaning Using

Cleaning Station" in the Instruction Manual.

Safe Clean station

environment setup

Configures various settings of the Safe-Clean Station function.

(1) You can select one from the head cleaning modes.

(2) You can change a value in [Setting head drying time].

For the operation procedure for (1) and (2) listed above, see

"11.1. Setting Head Cleaning Mode" in the Instruction

Manual.

(This setting is applied for only head cleaning.)

(3) You can set an automatic operation period in [Automatic

Circulation during Stop(S)].

See "".

Starts ink ejection using the Cleaning station.

If a fault is detected at the start of ink ejection, the nozzle is

automatically cleaned and ink ejection starts again.

For the operation procedure, see "11.3. Start Operation Using

Cleaning station" in the Instruction Manual.

Cleans the nozzle by using the Cleaning Station to suck makeup

from the nozzle orifice.

See "6.3.4. Nozzle Backwash (S)".

Cleans the recovery route by using the Cleaning Station to suck

makeup from the gutter.

See "6.3.3. Gutter Cleaning (S)".

Automatic

Circulation during

Stop(S)

Prevents sticking by using the Cleaning station to automatically

operate the unit periodically.

See "6.3.5. Automatic Circulation during Stop (S)".

Improving High

ink viscosity

Used at the occurrence of the [Ink Viscosity High] warning. The

ink viscosity is adjusted.

See "6.3.7. Improving High ink viscosity”.

Head Cleaning +

Ink Ejection (S)

Automatically performs the process from head cleaning to ink

ejection using the Cleaning station.

If a fault is detected at the start of ink ejection, the nozzle is

automatically cleaned and ink ejection starts again.

See "6.3.6. Head Cleaning + Ink Ejection (S)

*1 Gutter Cleaning (S) is not available to Short print head (Optional parts)

Loading...

Loading...