31

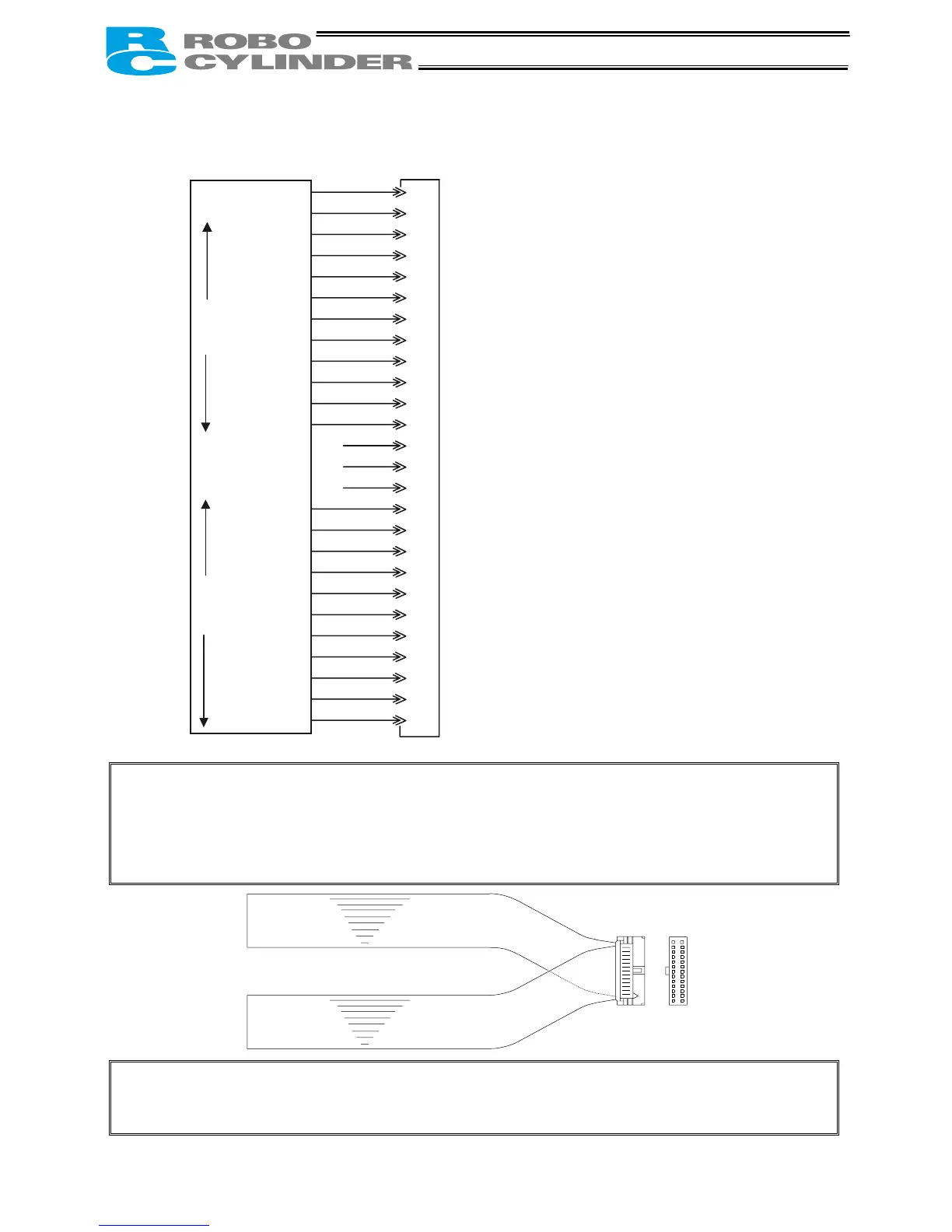

z PIO pattern 4 [Teaching]

Note: The factory-set PIO pattern is [Conventional], so change the value in user parameter No. 25 to

“4.”

To enable the servo ON signal, be sure to set user parameter No. 21 to “0.”

Be sure to enable the pause signal using user parameter No. 15 (by setting the parameter to

“0”) (the pause signal is enabled at the factory). The system cannot switch to the teaching

mode if the pause signal is disabled (i.e., the above parameter is set to “1”).

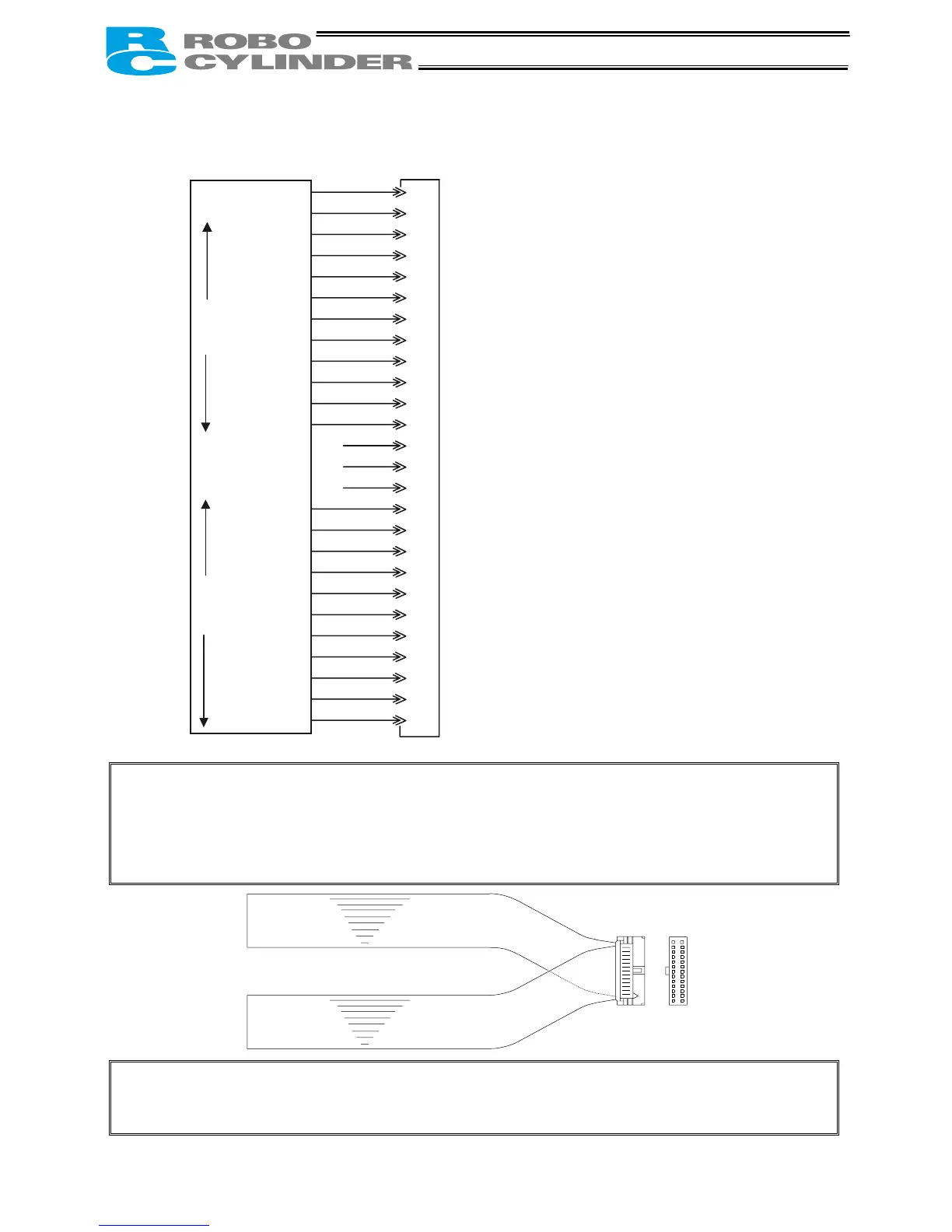

Note: When performing a continuity check of the flat cable, pay due attention not to expand the

female pins in the connector. It may cause contact failure and disable normal operation of the

controller.

1A P24

2A N

3A PC1

4A PC2

5A PC4

6A PC8

7A MODE

8A *STP/JOG +

9A CSTR/PWRT

10A HOME

11A SON

12A RES/JOG -

13A

1B

2B

3B PM1

4B PM2

5B PM4

6B PM8

7B MODES

8B MOVE

9B PEND/WEND

10B HEND

11B *EMGS Available on “RCP2-C.” Not used on “RCP2-CG.”

12B SRDY

13B *ALM

Brown 1

Red 1

Orange 1

Yellow 1

Green 1

Blue 1

Purple 1

Gray 1

White 1

Black 1

Brown 2

Red 2

Orange 2

Yellow 2

Green 2

Blue 2

Purple 2

Gray 2

White 2

Black 2

Brown 3

Red 3

Orange 3

Yellow 3

Green 3

Blue 3

Controller end

PIO (signal abbreviation)

Output side

+24 [V]

0 [V]

Command position 1

Command position 2

Command position 4

Command position 8

Operation mode

Pause/+Jog

Start/Position write

Home return

Servo ON

Reset/–Jog

Completed position 1

Completed position 2

Completed position 4

Completed position 8

Current operation

mode

Moving

Position complete/

Write completion

Home return

completion

Emergency stop

Ready

Alarm

Input side

Upper

stage

Lower

stage

(Note) *STP, *ALM and *EMGS are based on the negative logic.

Host system <PLC> end

13A

13B

1A

1B

Lower stage

Upper stage

Loading...

Loading...