3. Operation

Fieldbus Communication

121

RCP6

3.4.7 Control Signals for Positioner 3 Mode

This is the operation mode with the position No. set up.

The operation is to be made by using the position data set in the position table.

This is the mode with the minimum amount of input and output signals and the sent and

received data in 1-word.

The settable No. of position data items is max 256 points.

The main functions of ROBO Cylinder capable to control in this mode are as described in the

following table.

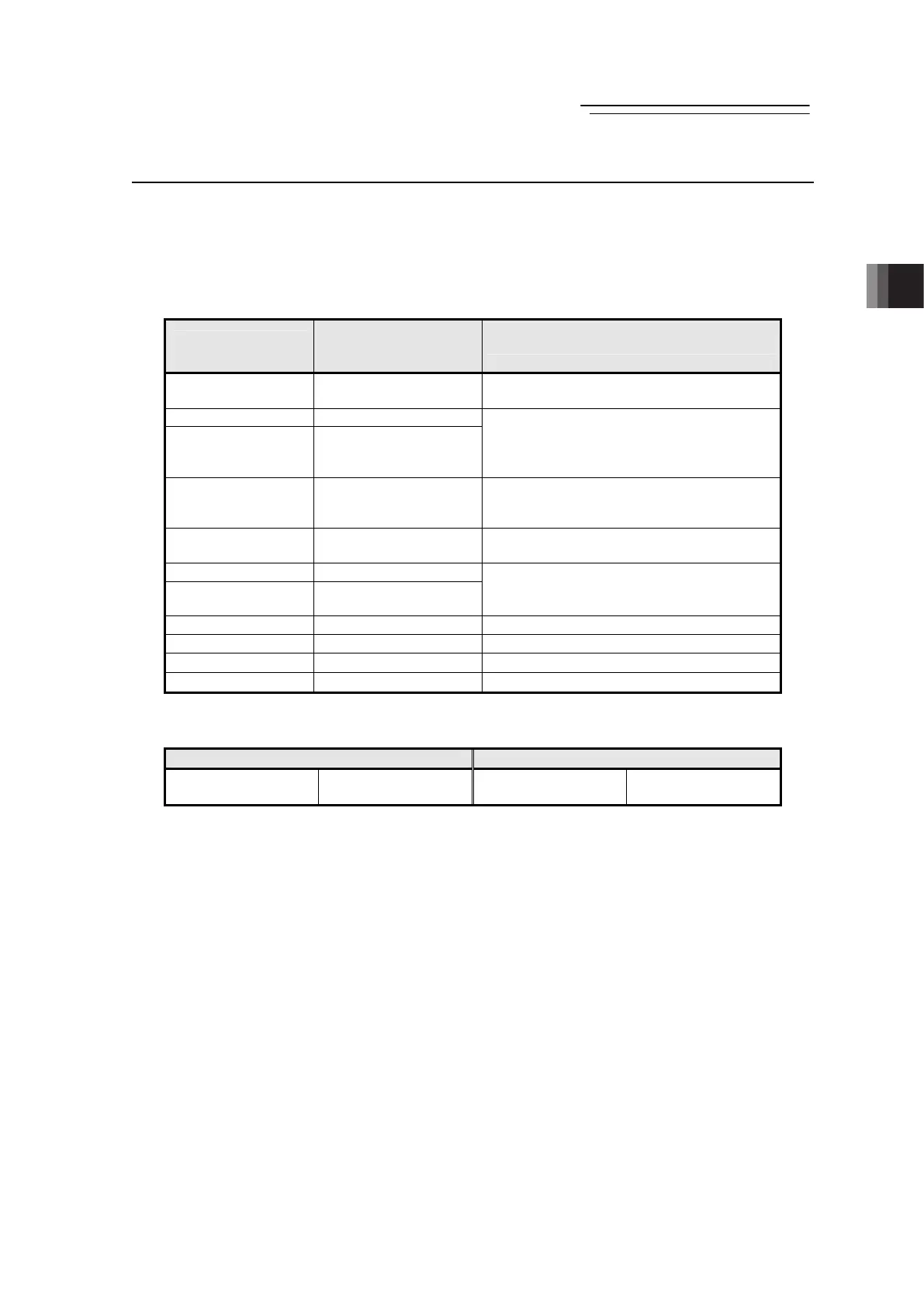

ROBO cylinder

function

{: Direct control

∆ : Indirect control

× : Disabled

Remarks

Home-return

operation

{

Positioning operation ∆

Speed and

acceleration/

deceleration setting

∆

These items must be set in the position data

table.

Separate settings for

acceleration and

deceleration

∆

Pitch feed

(incremental)

×

Pressing operation ∆

Speed change during

movement

∆

These items must be set in the position data

table.

Pause

{

Zone signal output ∆ These items must be set in the parameters.

Position zone signal

×

PIO pattern selection

×

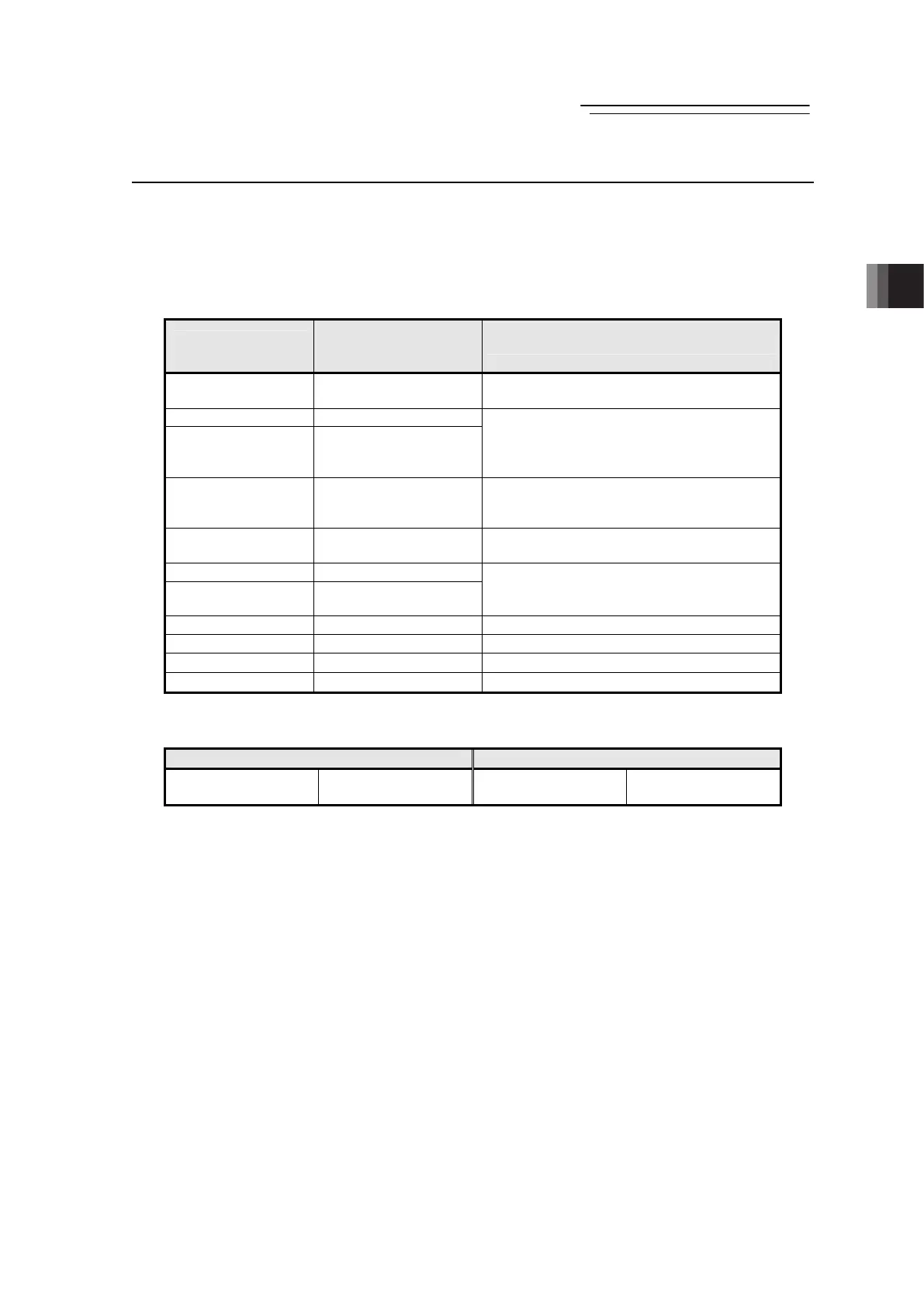

(1) PLC Address Composition

(m is PLC input and output top word address for each axis number)

PLC → RCP6S GW (PLC Output) RCP6S GW → PLC (PLC Input)

Control Signal/

Specified Position No.

m

Status Signal/

Completion Position No.

m

[Refer to Section 3.4.2 for the address maps for each Fieldbus.]

Loading...

Loading...