8. Parameter

Fieldbus Communication

226

RCP6

8.3.2 Adjustment of Brushless DC Electric Motor

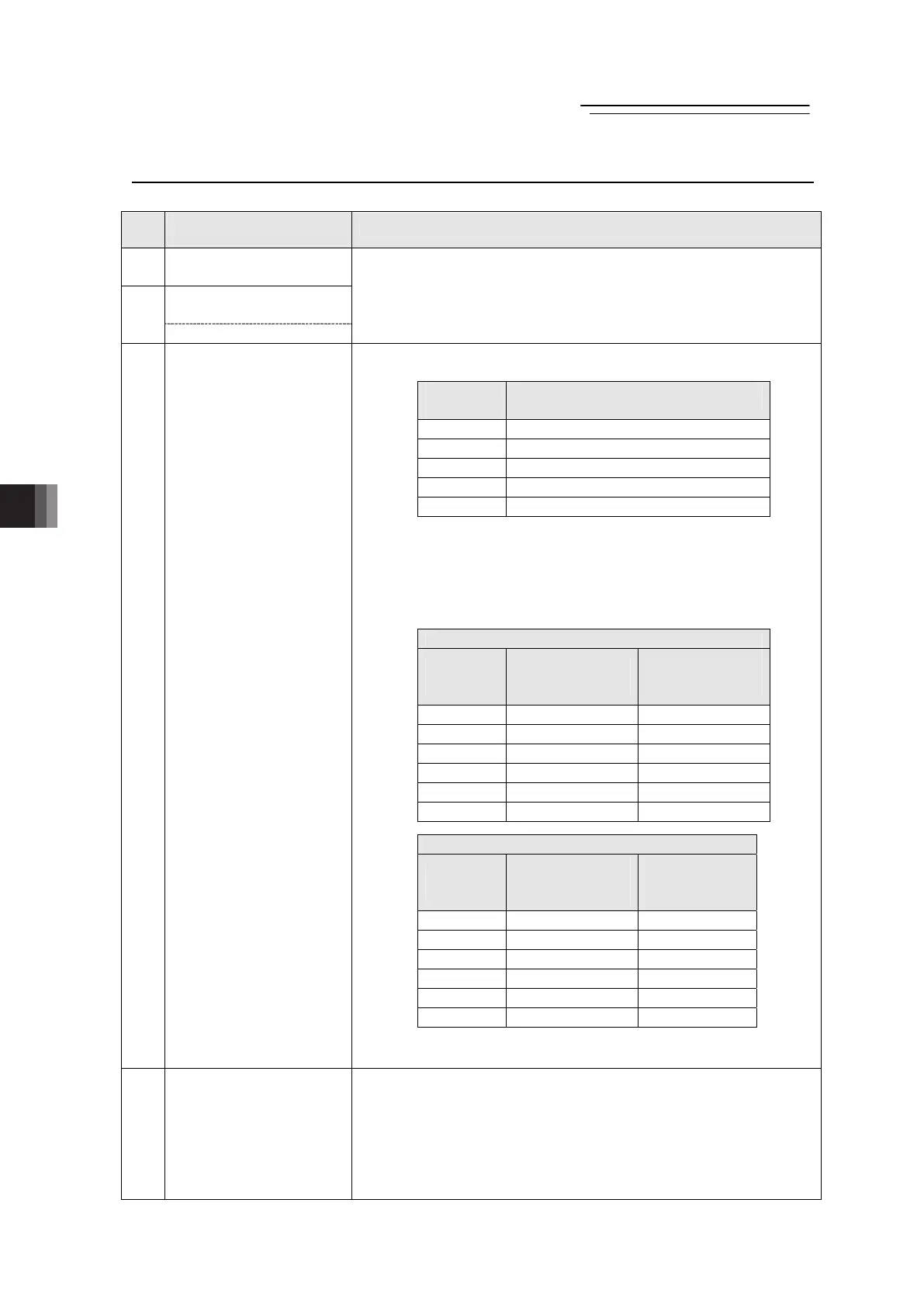

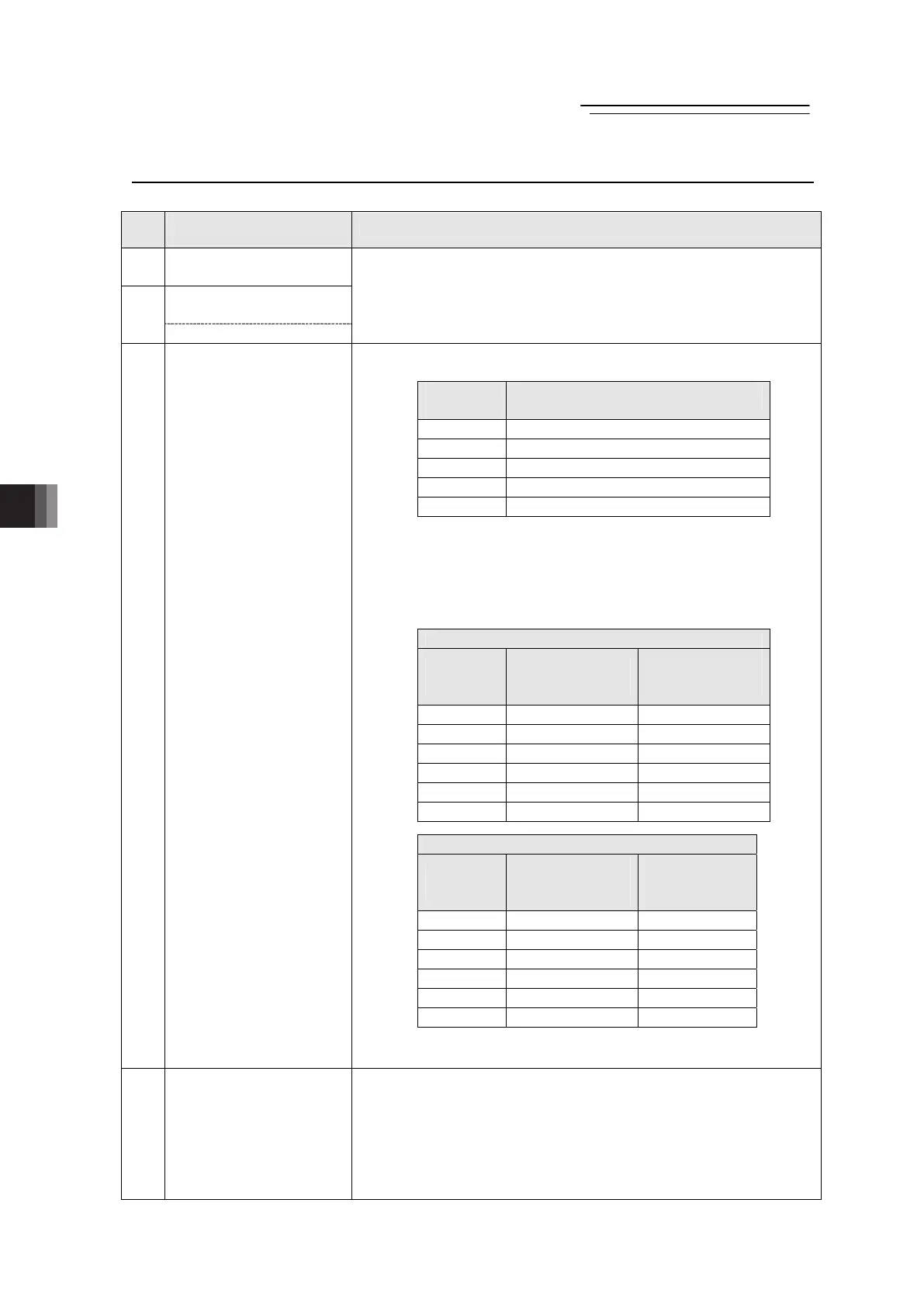

No.

Situation that requires

adjustment

How to Adjust

1

Hunching occurs at

positioning stop

Fluctuation in speed

occur during operation

2

Speed is inaccurate

Set the parameter in the following steps, and check the operation.

If an improvement is confirmed in operation, finish the adjustment.

It is not necessary to proceed to the next step.

Procedure 1 :

Change Parameter No. 32 “Velocity Loop Integrated Gain”

Set the five types of values below in order, and check the operation.

Setting

Order

Velocity Loop Integrated Gain

Setting

1 411

2 592

3 925

4 1645

5 3700

Go onto Procedure 2 if there is no improvement in operation.

Procedure 2 : Change Parameter No. 31 “Velocity Loop

Proportional Gain” and Parameter No. 32 “Velocity

Loop Integrated Gain”

Set the six types of values below in order, and check the operation.

●Load of 0.2kg or less

Setting

Order

Velocity Loop

Proportional

Gain Setting

Velocity Loop

Integrated Gain

Setting

1 42 382

2 42 520

3 42 749

4 42 1171

5 42 2081

6 42 4683

●Load over 0.2kg

Setting

Order

Velocity Loop

Proportional

Gain Setting

Velocity Loop

Integrated

Gain Setting

1 32 231

2 32 315

3 32 453

4 32 708

5 32 1259

6 32 2833

Contact IAI if there is no improvement in operation.

3 Abnormal noise is

generated / Especially,

when stop or operation

in low speed (less than

20mm/sec),

comparatively high noise

is generated.

Change the values for Parameter No. 31 “Velocity Loop

Proportional Gain” and

Parameter No. 32 “Velocity Loop

Integrated Gain” to the following.

Speed loop proportional gain : 32

Speed loop integral gain : 231

Loading...

Loading...