9. Troubleshooting

Fieldbus Communication

237

RCP6

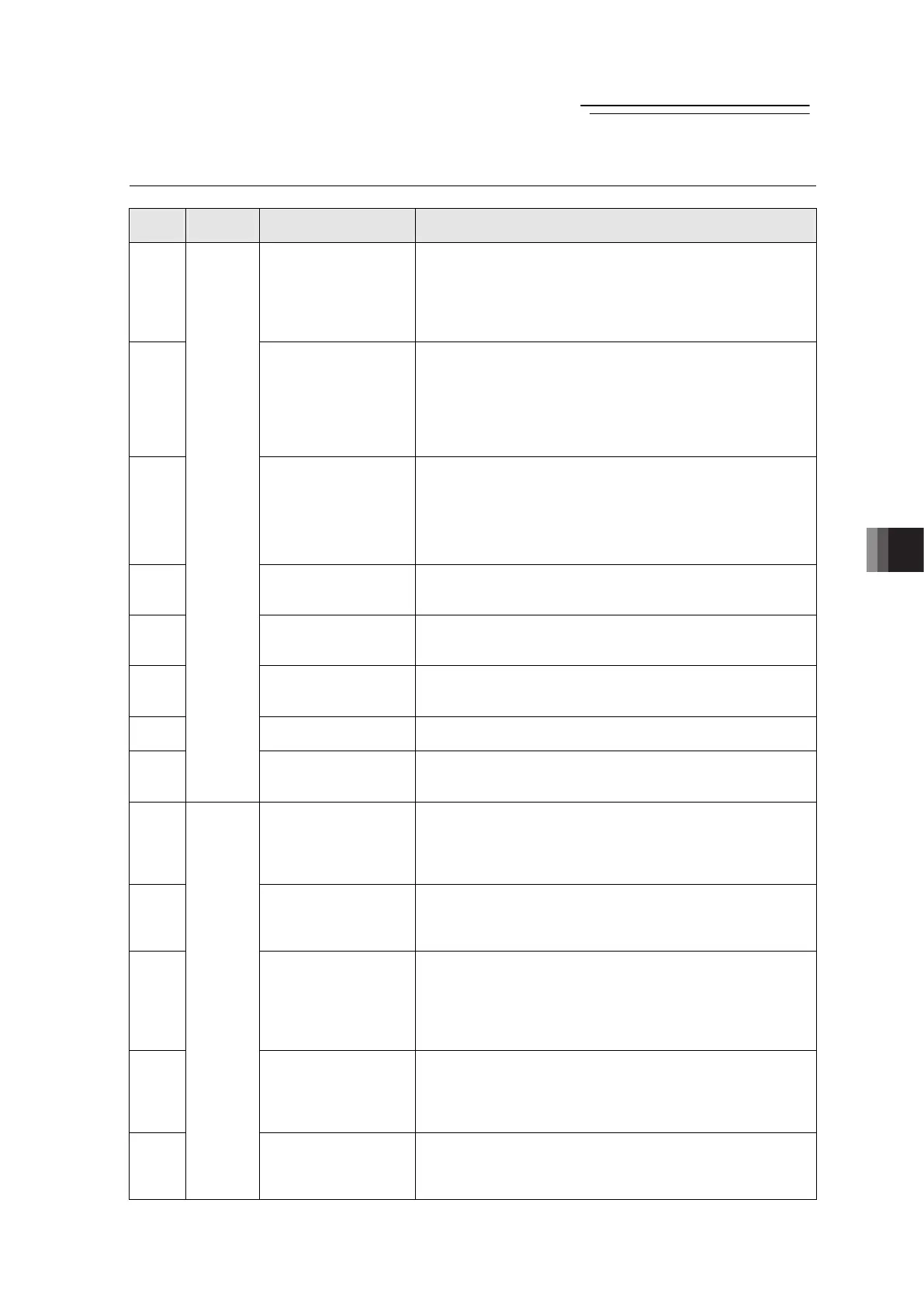

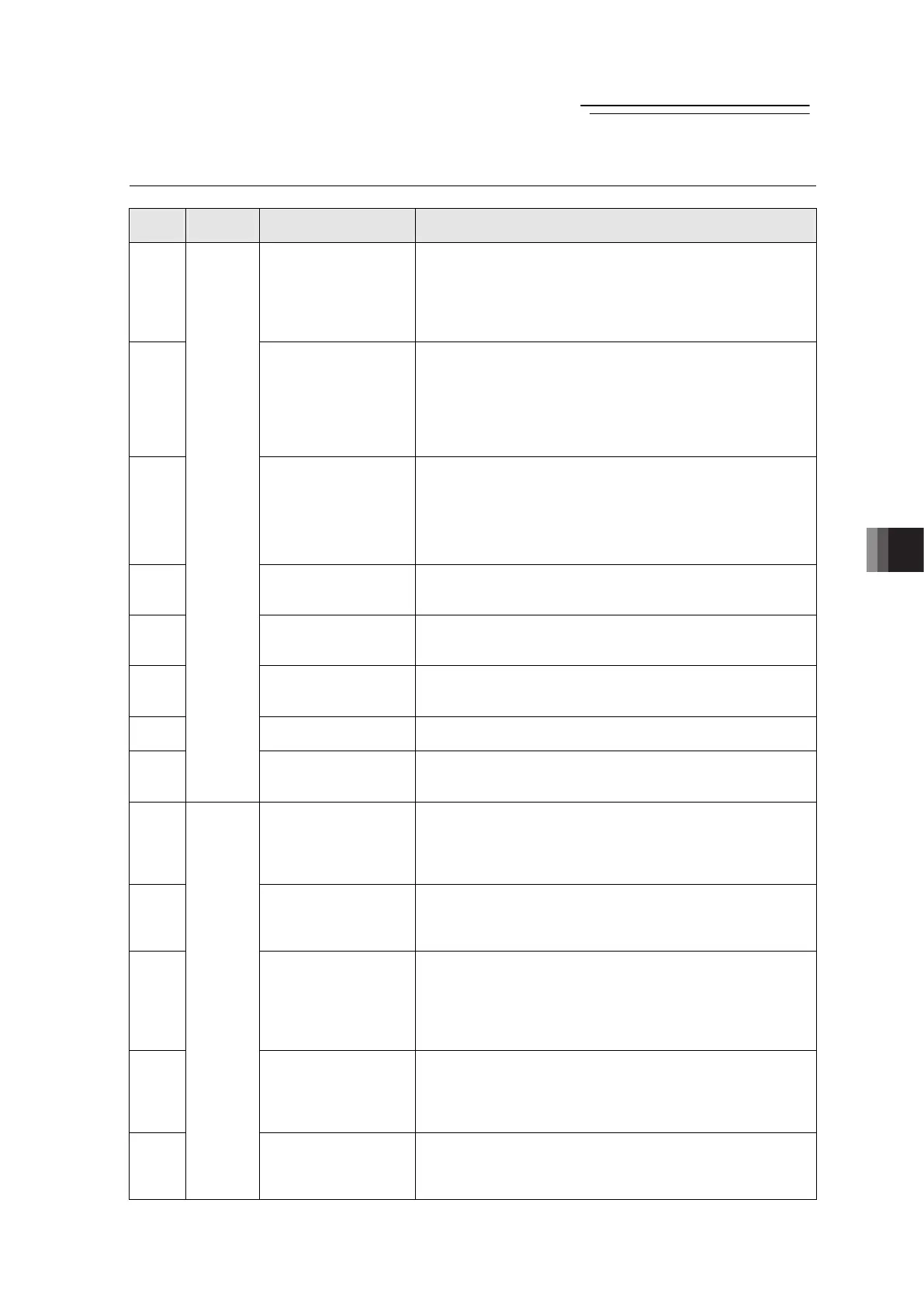

9.4.3 Alarm Codes for Driver Board

* In the alarm code list, description of P6PC shows RCM-P6PC, P6AC shows RCM-P6AC and P6DC shows RCM-P6DC.

Alarm

Code

Alarm

Level

Alarm Name Cause/Treatment

047 Deviation Overflow

Warning

Cause : The current operational condition or the sliding

resistance of the actuator is large, and there is a

concern of the deviation overflow being occurred.

Treatment : Reduce the acceleration setting.

Have a maintenance work conducted to supply

grease and so on.

048 Driver overload alarm Cause : The load current exceeded the value set in

Parameter No.143 “Overload Level Ratio”.

This alarm should turn on when the overload

current has risen from below exceeded the setting

and the alarm will be kept on until reset is held.

Treatment : Lower the setting of acceleration/deceleration. Also,

increase the frequency of pause.

049

For

RCP6S

and

P6PC

only

Collision alarm Cause : Motor current has reached the detection current set

in the collision detection feature.

Treatment : Remove the cause of collision.

If it is an unexpected detection, re-adjust the

collision detection feature.

[Refer to Chapter 5 Collision Detection Feature]

04E Exceeded movement

count threshold

Cause : The total number of the operation times exceeded

the value set in Parameter No.147 “Total Movement

Count Threshold”.

04F Exceeded operated

distance threshold

Cause : The total number of the operation distance

exceeded the value set in Parameter No.148 “Total

Operated Distance Threshold”.

05C Receiving timeout Cause : Valid data was not detected even after 5 seconds

has passed since the start (header) of Modbus

communication was detected.

05E Delimiter error packet

receive

Cause : Valid data cannot be detected with Modbus

communication, or abnormal data was received.

06B

Message

Maintenance

information data error

Cause : The maintenance information (total movement

count, total operated distance) is lost.

Treatment : Please contact IAI.

080 Move command in servo

OFF

Cause : A move command was issued when the servo is

OFF.

Treatment : Issue a movement command after confirming the

servo is ON (servo ON signal (SV) or position

complete signal (PEND) is ON).

082 Position command in

incomplete home return

Cause : A position move command was issued before home

return was completed.

Treatment : Issue a command after confirming that home return

has been completed (HEND) is ON.

083 Numerical command in

incomplete home return

Cause : An absolute position command was issued by

numerical specification before home return was

completed (direct command from Field Network).

Treatment : Issue a numeric specification after performing home

return operation and confirming the complete signal

(HEND).

084 Absolute position move

command when home

return is not yet

completed

Cause : A move command was issued when home return

was still in progress.

Treatment : Issue a movement command after performing home

return operation and confirming the complete signal

(HEND).

085

Operation

release

Position No. error during

movement

Cause : A non-existing (invalid) position number was

specified in the positioner mode.

Treatment : Check the position table again and indicate an

effective position number.

Loading...

Loading...