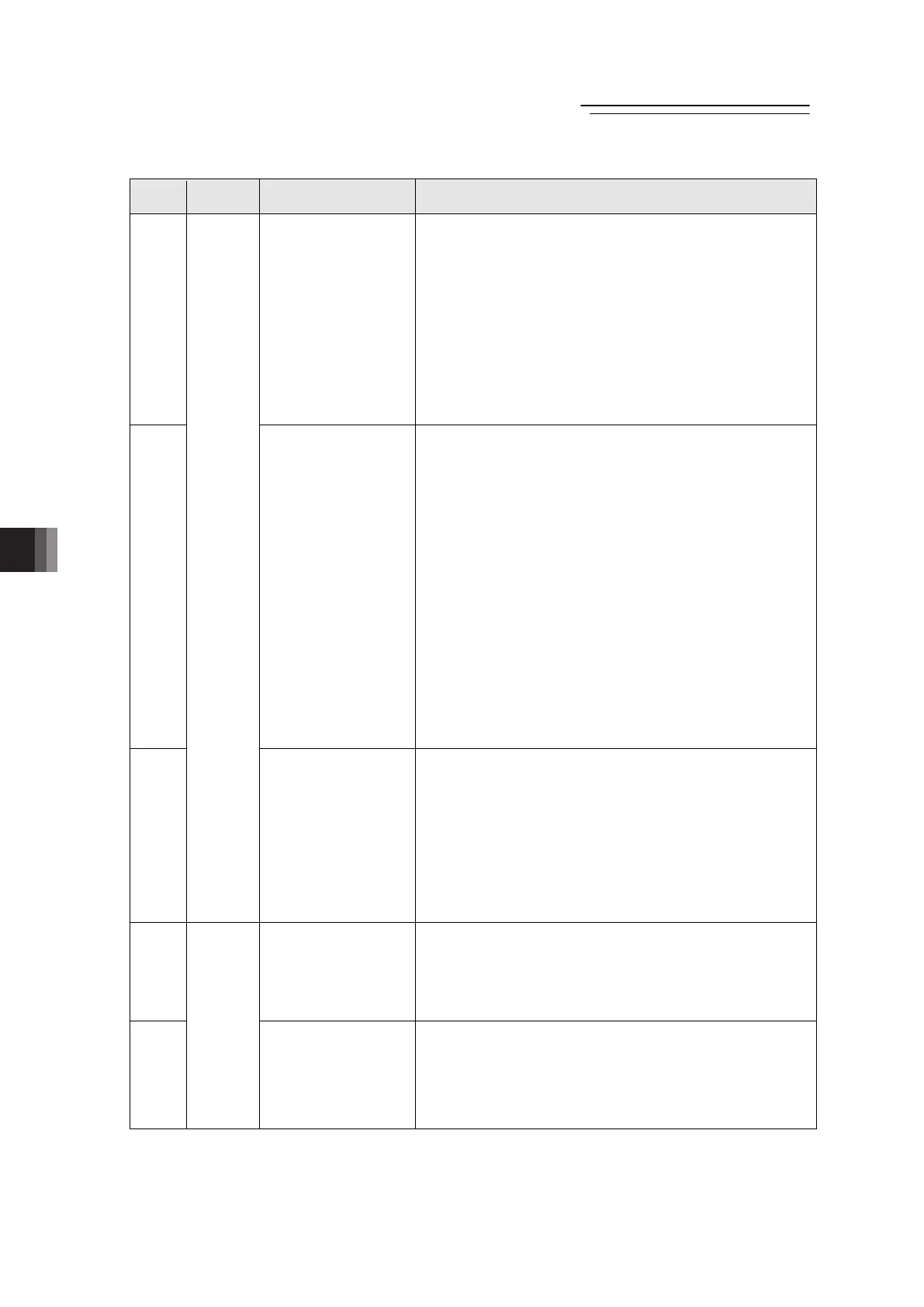

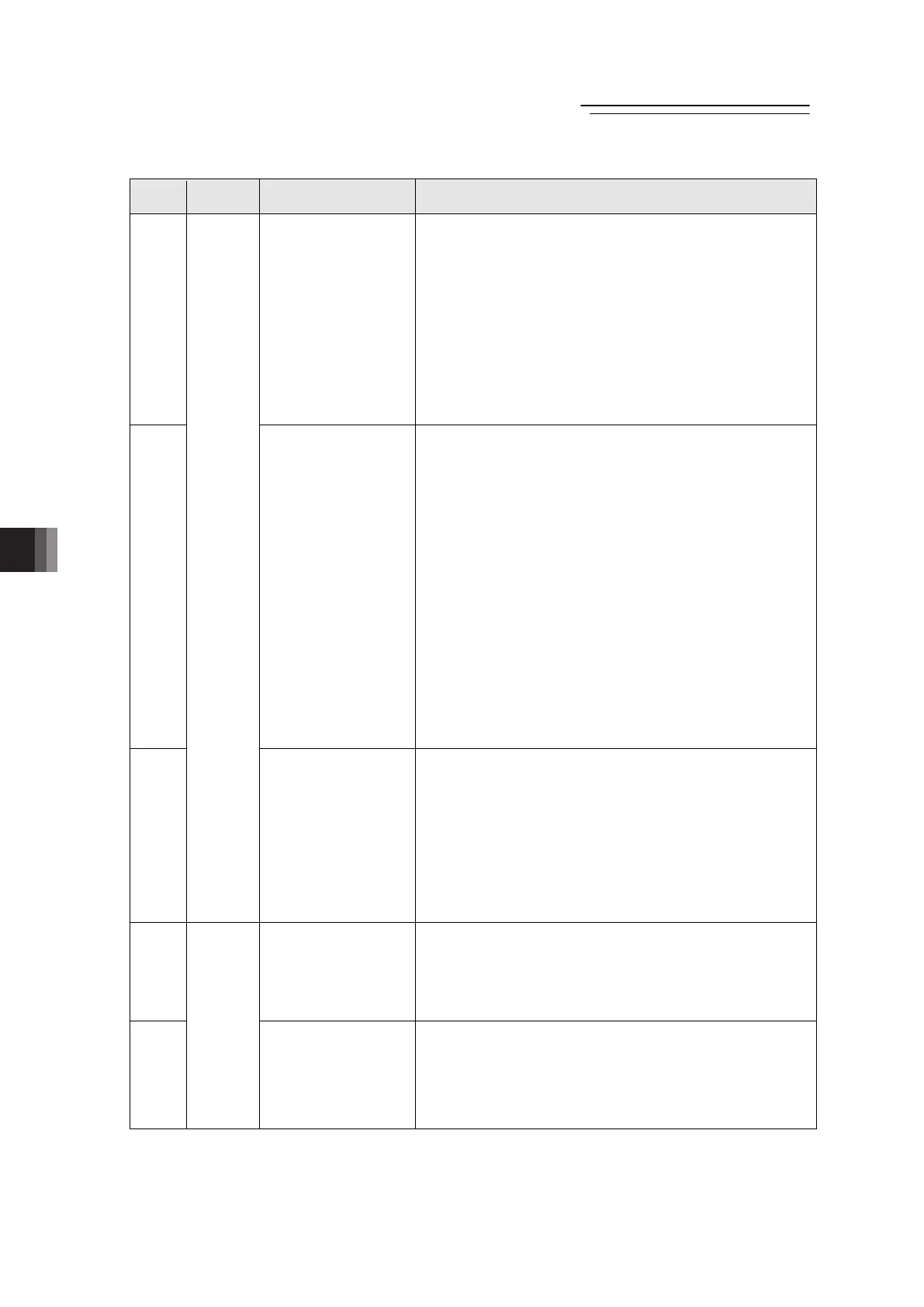

9. Troubleshooting

Fieldbus Communication

242

RCP6

* In the alarm code list, description of P6PC shows RCM-P6PC, P6AC shows RCM-P6AC and P6DC shows RCM-P6DC.

Alarm

Code

Alarm

Level

Alarm Name Cause/Treatment

0C0 Actual speed excessive Cause : This indicates the number of motor rotation

exceeded the number of allowable rotation.

1) The slide resistance of the actuator is locally high.

2) The load is increased too much due to a external

force.

With the reasons above, it can be considered a

sudden speed increase has occurred before

detecting the servo error.

Treatment : Even though this would not occur in normal

operation, check if there is any abnormality in the

parts assembly condition. Also check if there is a

possibility that an external force may be applied in

the direction of the actuator movement.

0C1

For

RCP6S

and

P6PC

only

Servo error Cause : It indicates 2 seconds has passed without making a

move since a move command was received.

1) Connection error or wire breakage of

motor/encoder cables.

2) Brake is not released (when equipped with a

brake).

3) Load to the motor is high due to external force.

4) The resistance in the actuator sliding operation

is large.

Treatment : 1) Check for the motor/encoder cable wiring

condition.

2) Supply 24V DC 150mA to the BKRLS terminal

on the power supply connector and if you can

see an improvement, it is considered the

controller failure. Please contact IAI.

3) Confirm that there is no error in the mechanical

part assembly condition.

4) If the loaded weight is within the allowable range,

turn the power OFF and check the resistance in

sliding operation by moving the slider with hand.

0C5

For

P6AC

and

P6DC

only

Operation

release

Illegal transition

command in control

system

Cause : 1) Change the operation from the vibration

suppress control operation to the normal

position control operation.

2) Change the operation from the normal position

control operation to the vibration suppress

control operation.

Treatment : Change the sequence so the next action is

conducted after confirming the positioning complete

signal (PEND) is turned ON for both cases 1) and

2).

0C8 Overcurrent Cause : The output current in the power circuit section is

increased abnormally.

Treatment : This alarm will not be generated in normal

operation. It can be considered as the insulation

degradation of the motor winding or malfunction of

the controller. Please contact IAI.

0C9

For

RCP6S

and

P6PC

only

Cold start

Overvoltage Cause : The voltage on the power regenerative circuit

exceeded the threshold.

Treatment : Malfunction of the controller can be concerned.

Please contact IAI.

Loading...

Loading...