Goodrive270 series VFD for fan and pump Function parameter list

-146-

Name Description Default

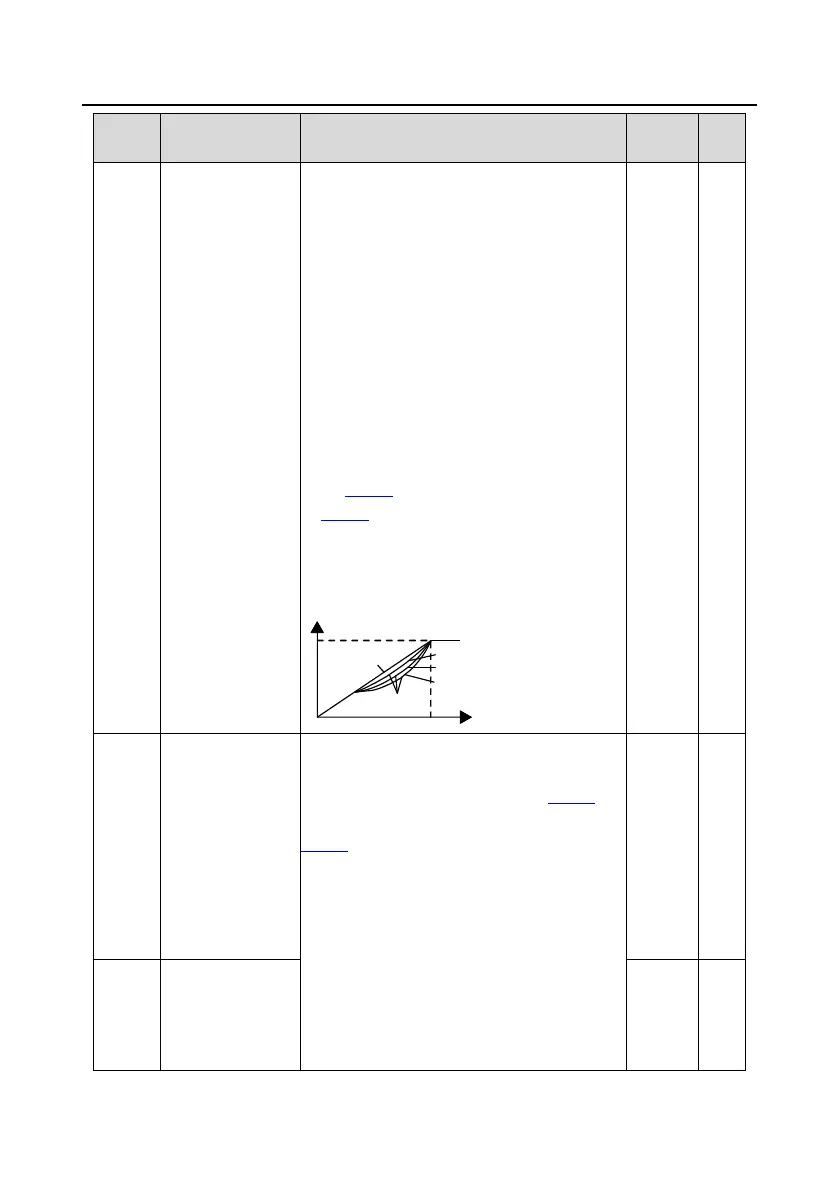

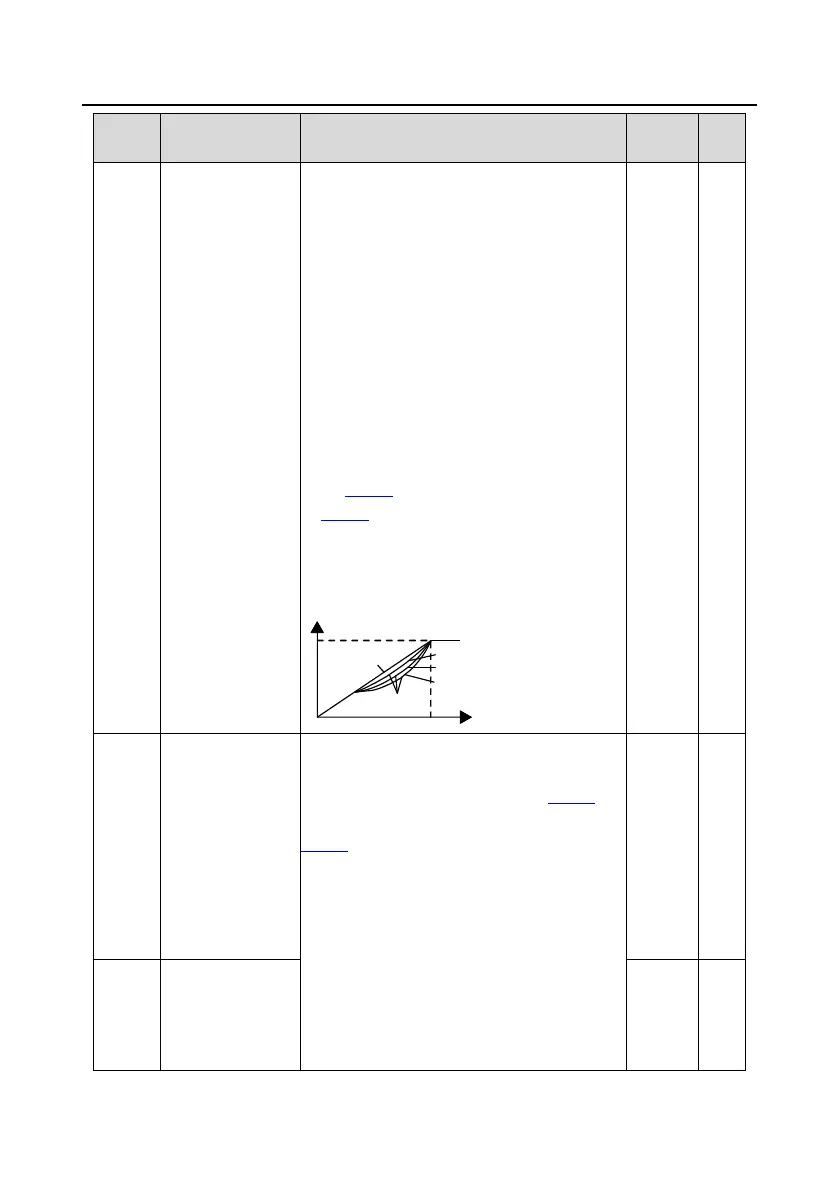

-point V/F curve

-down V/F curve (power of 1.3)

-down V/F curve (power of 1.7)

-down V/F curve (power of 2.0)

±4 are applicable for torque-variable

loads such as fan, pump and similar equipment.

You can make adjustment based on load

characteristics to achieve optimal energy

-

5: Customized V/F (V/F separation); in this

mode, V can be separated from F and F can be

adjusted through the fr

equency setting channel

P00.06 or the voltage setting channel set

P04.27 to change the characteristics of the

Note: In the following figure, V

b

is the motor

b

is the motor rated

Output voltage

Output frequency

Linear type

Square type

Torque step-down V/F curve (power of 1.3)

Torque step-down V/F curve (power of 1.7)

Torque step-down V/F curve (power of 2.0)

V

b

f

b

P04.01

Torque boost of

motor 1

In order to compensate for low

-

frequency torque

characteristics, you can make some boost

compensation for the output voltage.

P04.01 is

relative to the max. output voltage V

b

.

defines the percentage of cut-off

frequency of manual torque boost to the rated

motor frequency f

b

. Torque boost can improve

-frequency torque characteristics of V/F.

You need to select torque boost based on the

load. For example, large

r load requires larger

torque boost, however, if the torque boost is too

large, the motor will run at over

-

excitation, which

may cause increased output current and motor

overheating, thus decreasing the efficiency.

0.0% ƻ

P04.02

Torque boost cut-

of motor 1

20.0% ƻ

Loading...

Loading...