1-4

Basic Operations

When performing

checks before

commencing the work,

be sure to turn off the

main power switch.

Turn on the power

only when checking

the operation.

Accurate weighing

cannot be made if the

weighing unit is not

horizontally installed.

This section describes the methods of confirming accessories, checking the machine before operation, and

turning the machine on.

Be sure to check the following points before operation so the machine can be constantly

kept in good condition.

Use the following procedure when making a horizontal adjustment for the machine,

Check Points

Dirt on the weighing platter,

level window, display, and

stroke keys

Dirt on the thermal head

Dirt on the label set unit

Horizontal installation of the

weighing unit

Dirt on the roller of the label

set unit

Dirt on the peeling sensor

Rattling of the machine

Label paper feeding state

Measures to be taken

Wipe off dirt with a fully wrung-out soft cloth.

Remove extraneous matters such as dust and

labels and wipe them off with the thermal head

cleaner.

For details, see “Cleaning” on Page 1-10.

Remove extraneous matters such as dust and

labels.

Adjust the weighing unit to become horizontal

by turning the lock nut of each level adjustable

leg.

Place four rubber feet on the horizontal

mounting surface.

Adjust the print position by pressing the [FEED]

key.

Confirmation of the weighing

state

Confirm that weighing is performing normally.

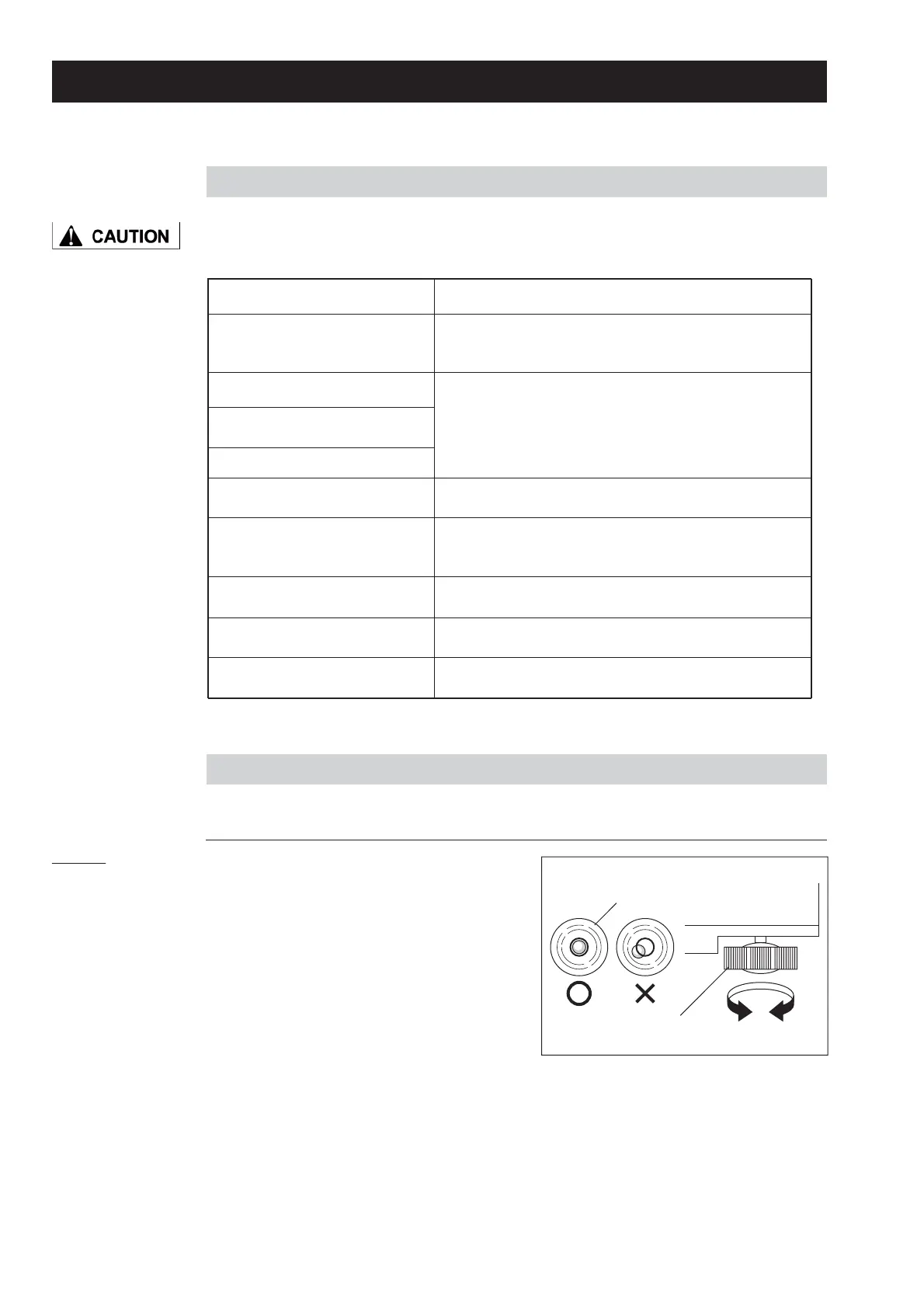

1.

Install the machine at a stable

and level location.

Adjust the weighing unit to become

horizontal by turning the lock nut of each

level adjustable leg so that an air bubble

in the level becomes centered.

Level

Level adjustable leg

1.3 PREPARATION BEFORE OPERATION

1.3.1 CHECK BEFORE OPERATION

1.3.2 MARKING A HORIZONTAL ADJUSTMENT

NOTE

Loading...

Loading...