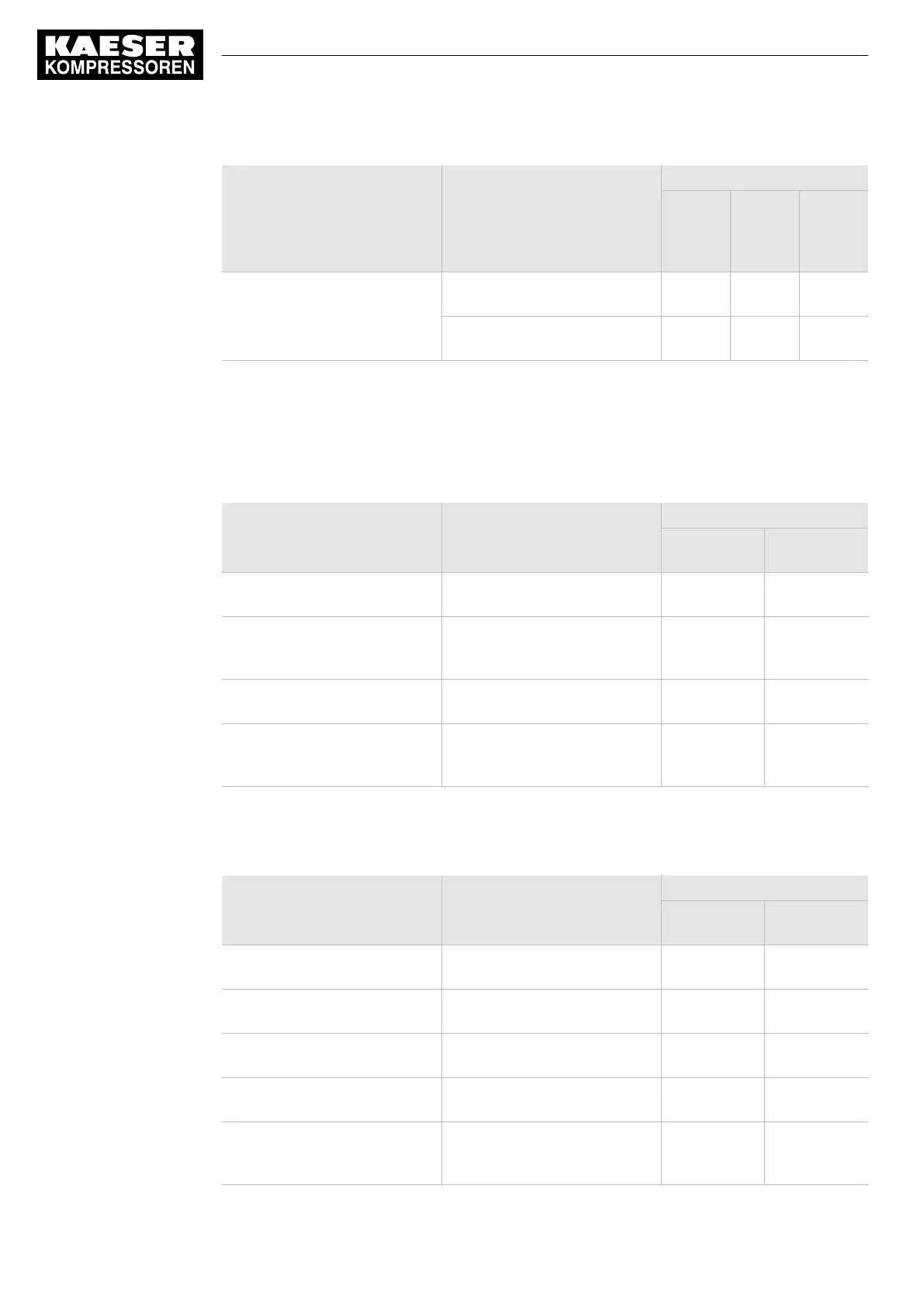

Possible cause Remedy Where can I get help?

Special‐

ized

work‐

shop

KAESER

Service

Engine

service

manual

Engine oil pressure too low. Check engine oil level, see

chapter 10.3.4

.

– – X

Check the engine and have re‐

paired if necessary.

X X –

Tab. 74 Indicator lamp remains on

9.3 Compressor faults and alarms

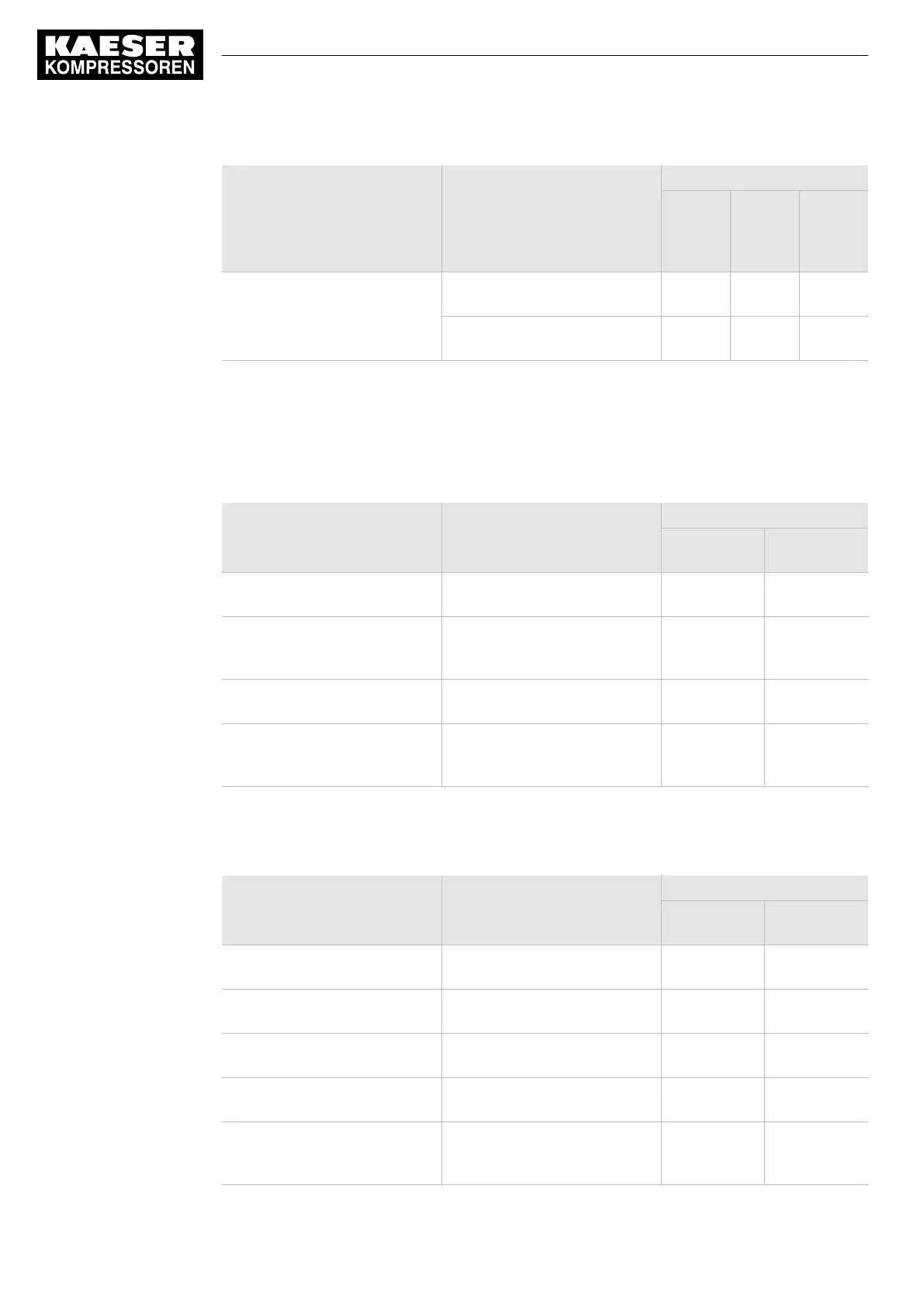

9.3.1 Working pressure too high

Possible cause Remedy Where can I get help?

Specialized

workshop

KAESER

Service

Proportional controller maladjus‐

ted or defective.

Have repaired or replaced if

necessary.

– X

Inlet valve does not close. Check the controller, the control

air line and the inlet valve and

replace if necessary.

– X

Pressure gauge indicating false

pressure.

Have repaired or replaced if

necessary.

– X

Venting valve does not blow off. Check the connections and

function and have repaired or

replaced as necessary.

– X

Tab. 75 Fault: Working pressure too high

9.3.2 Working pressure too low.

Possible cause Remedy Where can I get help?

Specialized

workshop

KAESER

Service

Proportional controller maladjus‐

ted or defective.

Have repaired or replaced if

necessary.

– X

Inlet valve not opening or only

opening partially.

Repair or have replaced if nec‐

essary.

– X

Pressure gauge indicating false

pressure.

Have repaired or replaced if

necessary.

– X

Pressure relief valve maladjus‐

ted and/or leaking.

Have repaired or replaced if

necessary.

– X

Venting valve does not close. Check the connections and

function and have repaired or

replaced as necessary.

– X

9 Fault Recognition and Rectification

9.3 Compressor faults and alarms

94

Operator Manual Screw Compressor

M100 No.: 9_6999 23 USE

Loading...

Loading...