2. Remove the battery (batteries) and store in a frost-free room.

3.

Make sure batteries are fully charged.

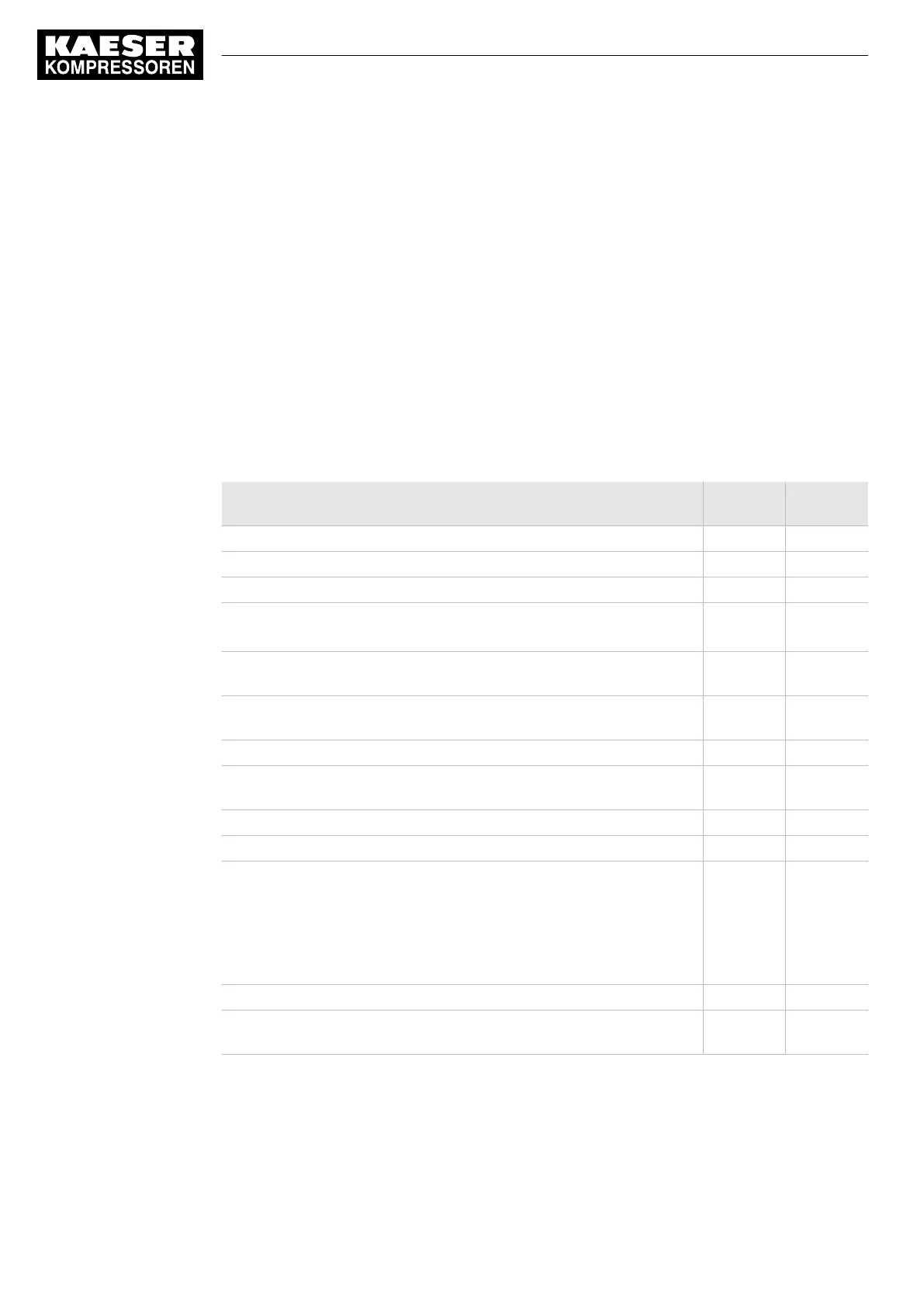

12.1.2 Long-term decommissioning and storage

Decommissioning the machine for 5 months or longer.

Material Receptacle

Preserving oil

Preservative

Desiccant

Plastic sheeting

Moisture-resistant adhesive tape

➤ The following measures must be taken for long-term decommissioning and storage:

Long-term decommissioning and storage tasks See

chapter

Confirmed?

➤ Check engine coolant. 10.3.1

➤ Drain the engine oil. 10.3.6

➤ Drain the oil from the oil separator tank and the oil cooler. 10.4.3

➤ Fill the separator tank and engine with preserving oil. 10.4.2

10.3.5

➤ Run the machine for about 10 minutes to coat all parts with a protec‐

tive oil film.

–

➤ Disconnect the battery, the minus terminal first and then the plus ter‐

minal, and store in a frost-free room.

–

➤ Check the battery fluid level. 10.6

➤ Check the battery charge monthly and recharge if necessary to pre‐

vent the battery fluid freezing.

–

➤ Clean the battery terminals and coat with acid-resistant grease. –

➤ Close the compressed air outlet valves. –

➤ Use plastic sheeting and moisture-resistant adhesive tape to seal off

the following openings:

■

Engine air inlet

■ Compressor air inlet

■ Exhaust silencer

–

➤ Clean the bodywork and treat with preservative. –

➤ Hang a notice on the instrument panel to inform of the decommis‐

sioning measures taken.

–

Tab. 96 Long-term decommissioning and storage checklist

12 Decommissioning, Storage and Transport

12.1 De-commissioning

228

Operator Manual Screw Compressor

M100

No.: 9_6999 23 USE

Loading...

Loading...