KCP Heavy Industries Co., Ltd. Maintenance

7-2

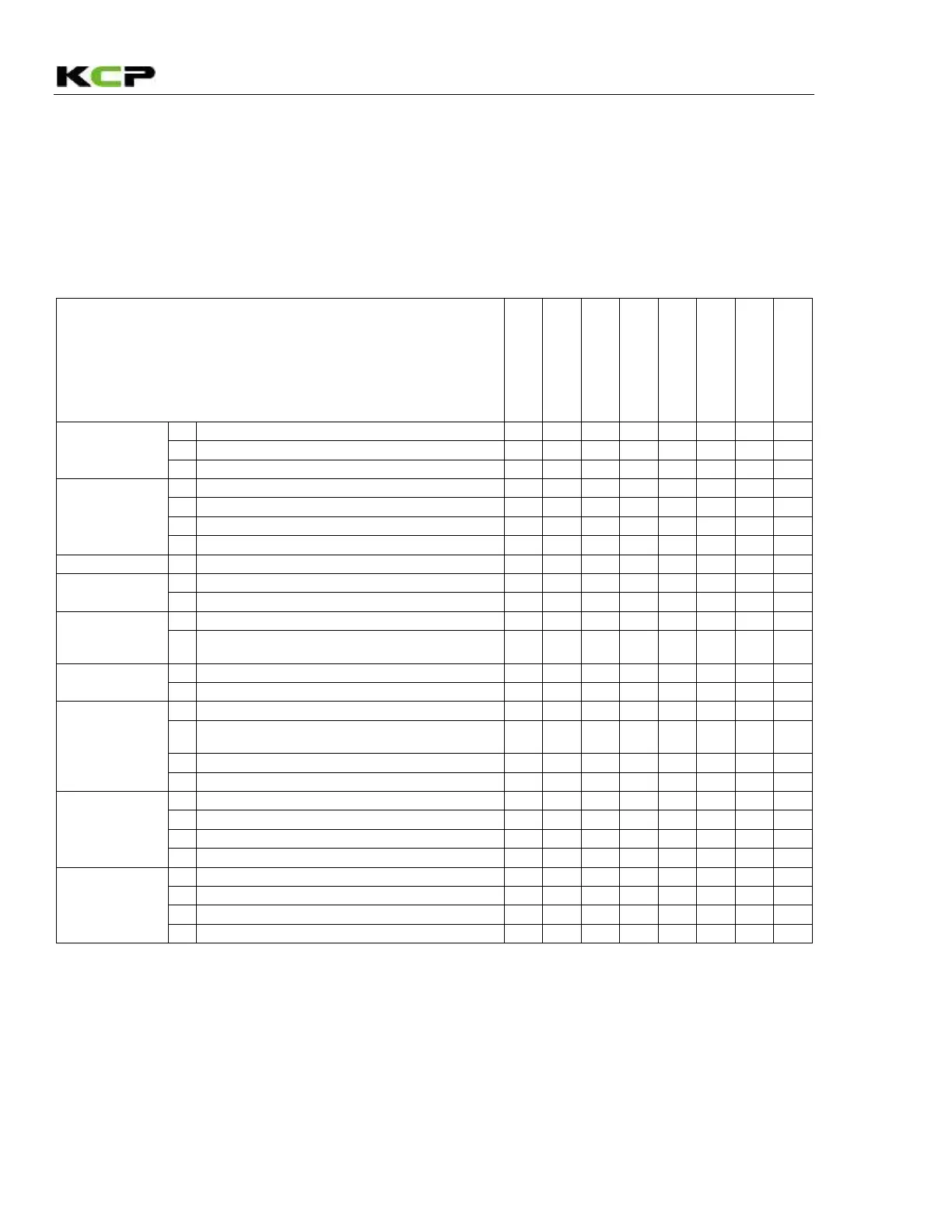

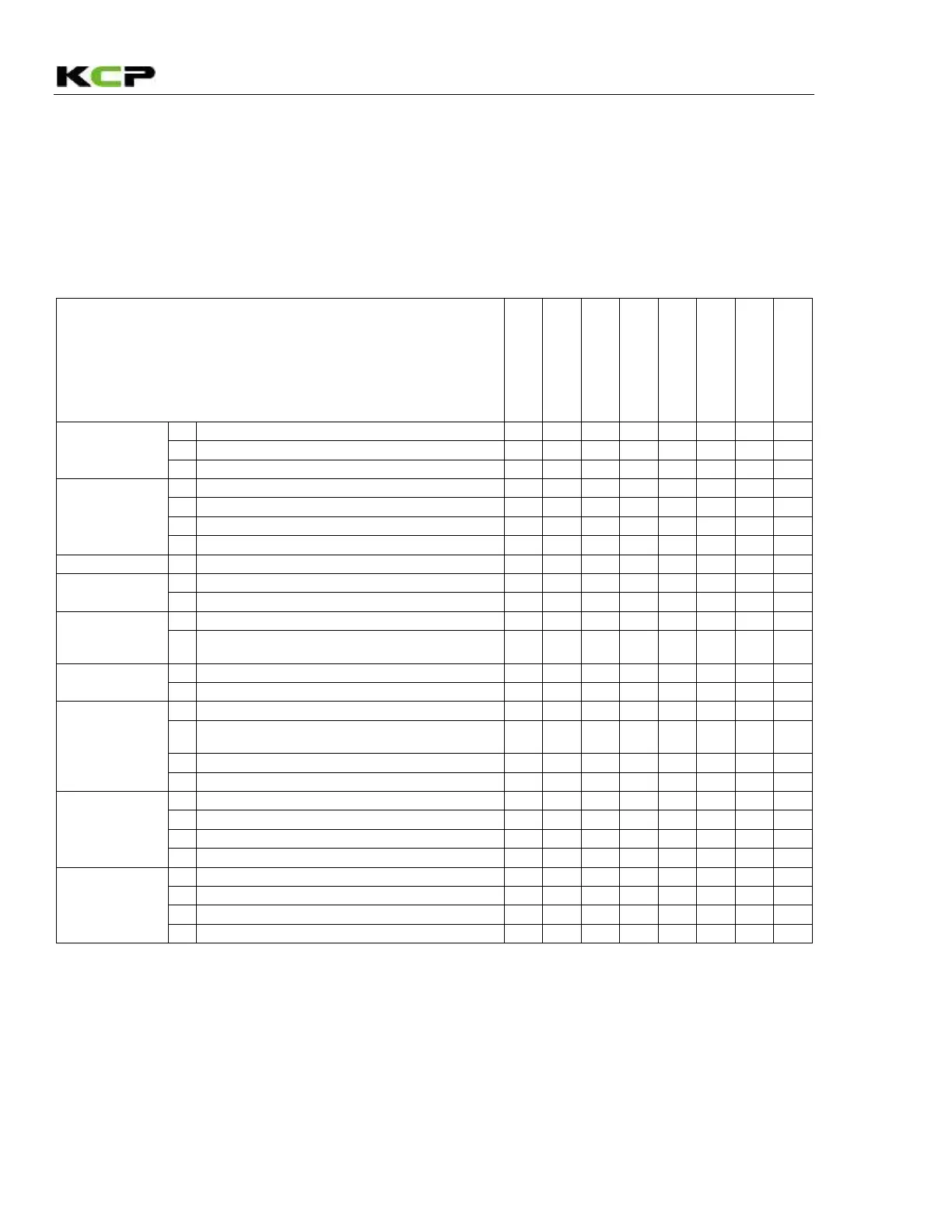

7.1 Maintenance intervals

The following table shows the intervals for the various maintenance tasks. The associated

maintenance can be located further on in this section.

Check emergency stop function

Check all electrical functions

Check hydraulic oil level

Drain off water from tank

Replace main filter (return filter)

Check condition of other components

Check for damaged wires (electrical models

only)

Check hoses for damage and fatigue

Check agitator safety switch for proper

operation

Check condition of wear parts

Check bolts for tightness

Check for proper operation

Check bolts on spacer flange

Drain and clean water box

Replace rubber pistons when worn out

Check wear condition of pipes

Check couplings on pressure pipes

Check pipe line support brackets

Loading...

Loading...