KCP Heavy Industries Co., Ltd. Operation

5-10

5.4 Cleaning

Concrete that is left behind are deposited inside the delivery line or transfer tube can cause

damage, will accumulate and reduce the cross-section. A clean delivery line and transfer

tube is therefore indispensable if you wish to be able to start pumping without problems on

the next job.

Concrete deposited around the wear ring can impair its function. For this reason, through

flushing of the wear ring is required at the end of a job, unless the next pumping job follows

within 30 – 60 minutes.

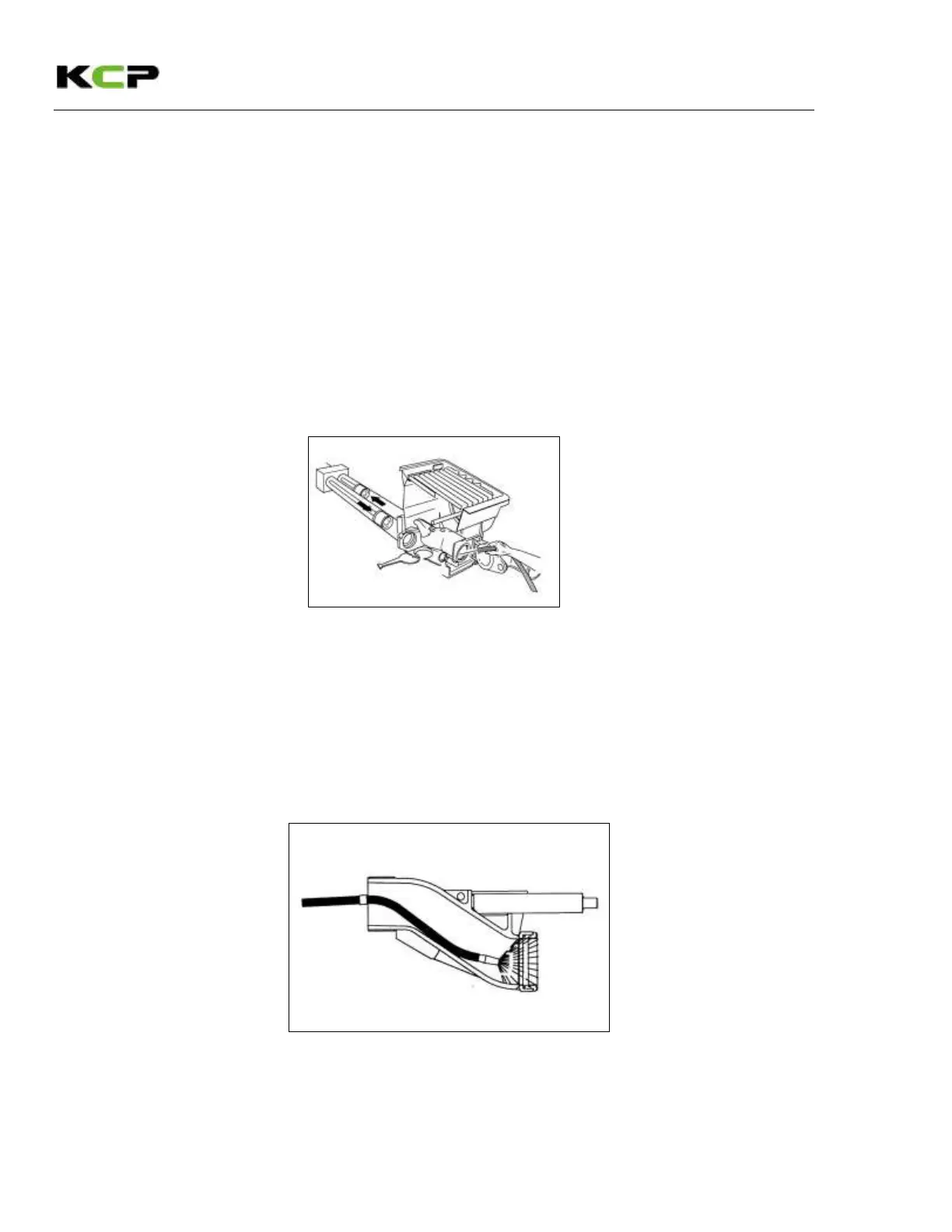

Spray out delivery cylinder

▶ Open the hinged elbow.

▶ Allow the concrete pump to run slowly in reverse.

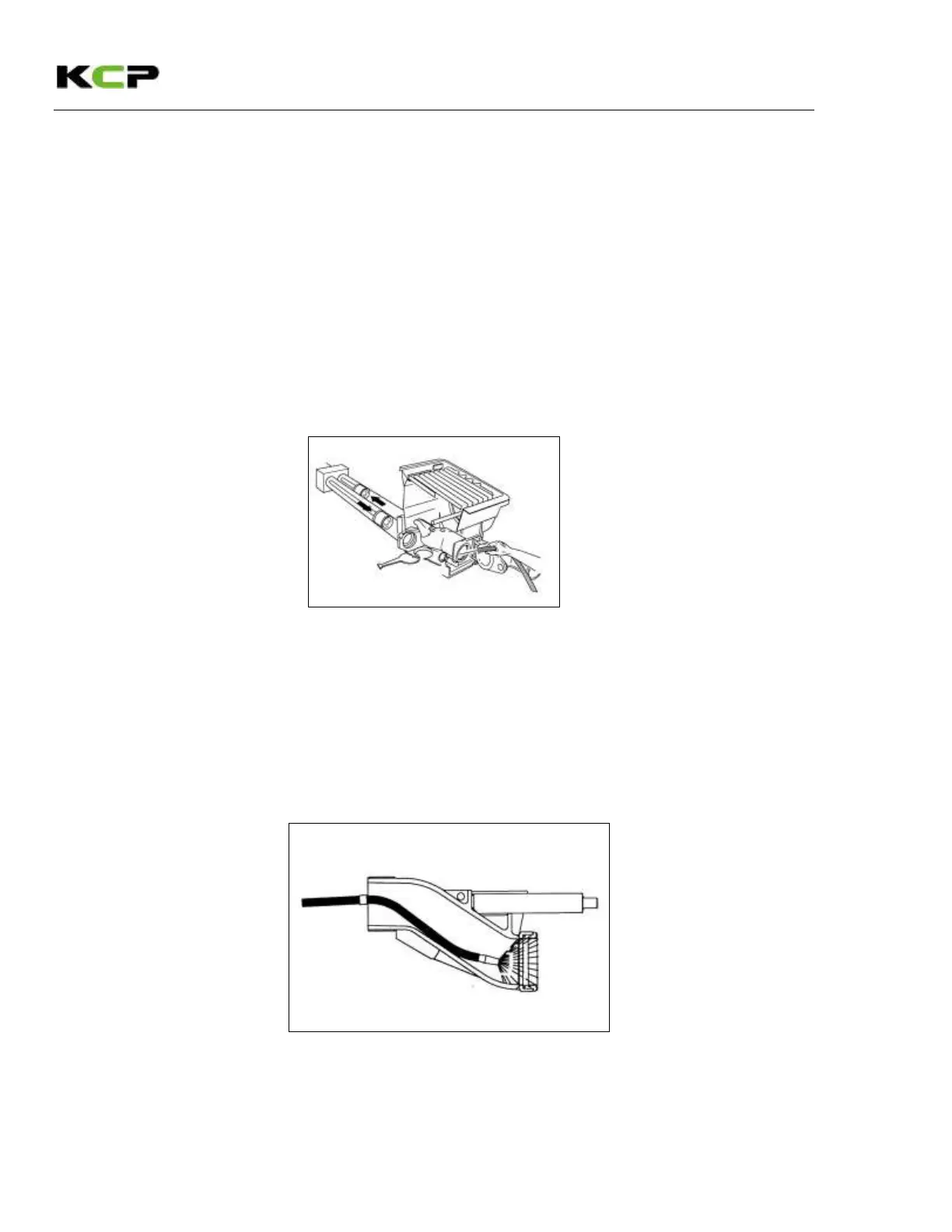

▶ Spray the transfer tube out carefully downwards from the hinged elbow. Slowly insert the hose

up to the marking as you do this (see the “Mark water hose” chapter).

▶ Hold the water hose in this position, introduced as far as the marking, for several minutes, until

only clean water runs out.

This will flush out the two delivery cylinders alternately.

▶ Carefully spray out the hopper using a hose.

▶ Hose down all components that have come into contact with concrete.

Loading...

Loading...