KCP Heavy Industries Co., Ltd. Maintenance

7-17

► Insert the spacer flange and fasten all the bolts.

► Tighten the bolts with the specified torque.

► Open the valve when rubber piston replacement is completed.

► Then carry out a test run.

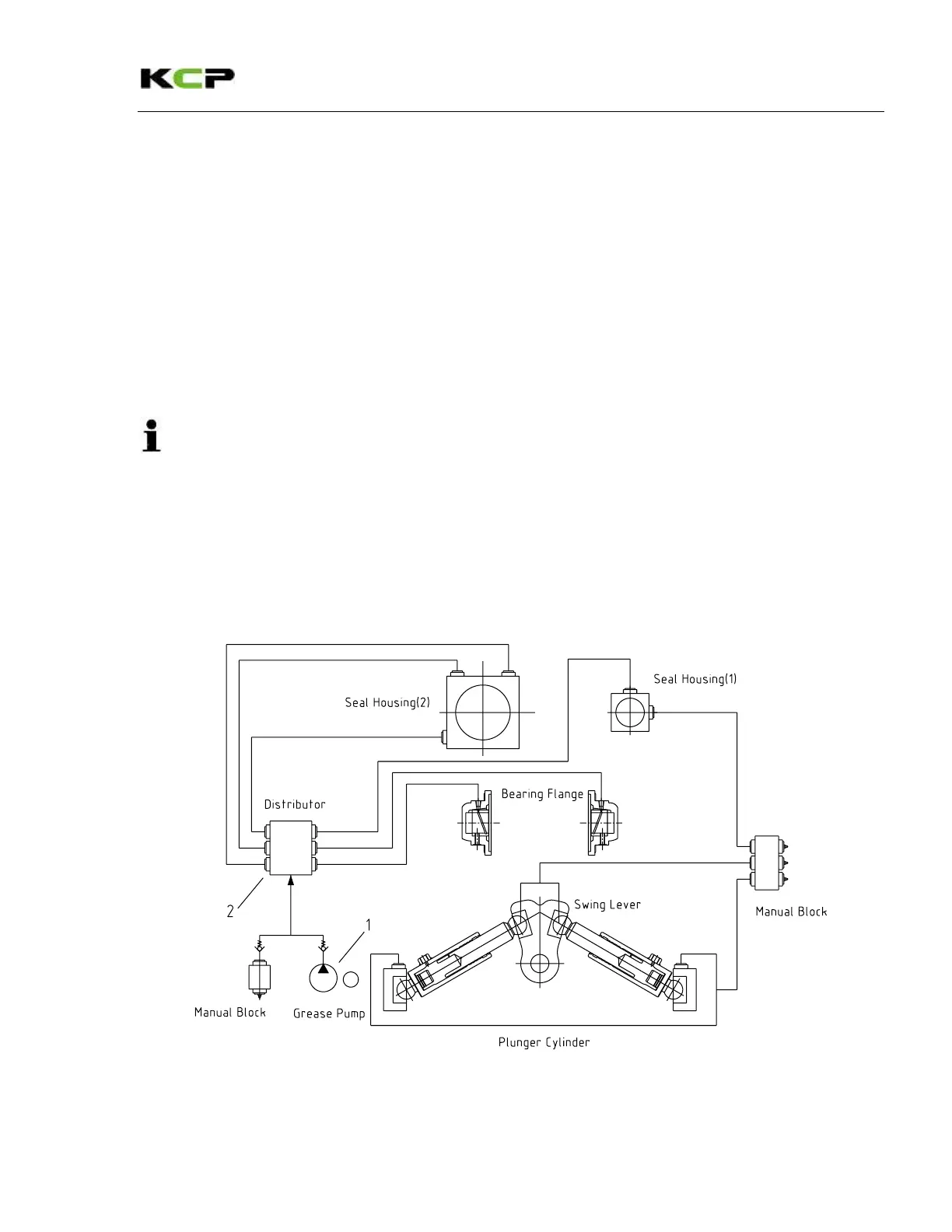

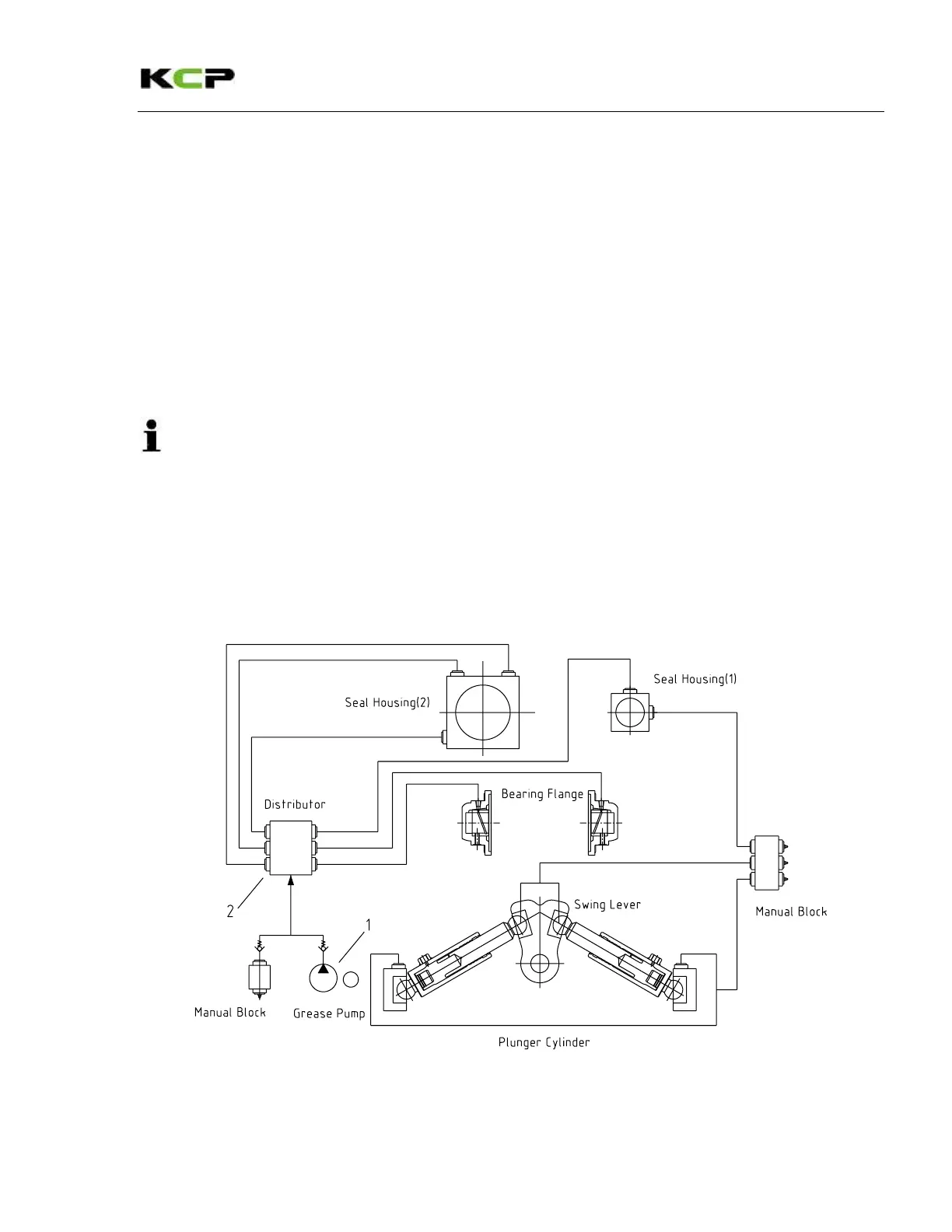

7.9 Lubricating hopper

This maintenance describes the lubrication of all lubricating points on the hopper. You will find the

maintenance intervals in the maintenance summary at the beginning of this chapter.

Note ___________________________________________________________________

Use lithium-based grease that is in accordance with NLGI 0 or 0.0.

____________________________________________________________________________

7.9.1 Lubrication intervals

Check the lubrication points after completing a job. Grease should be seeping through the seals

when the greasing is complete.

Loading...

Loading...