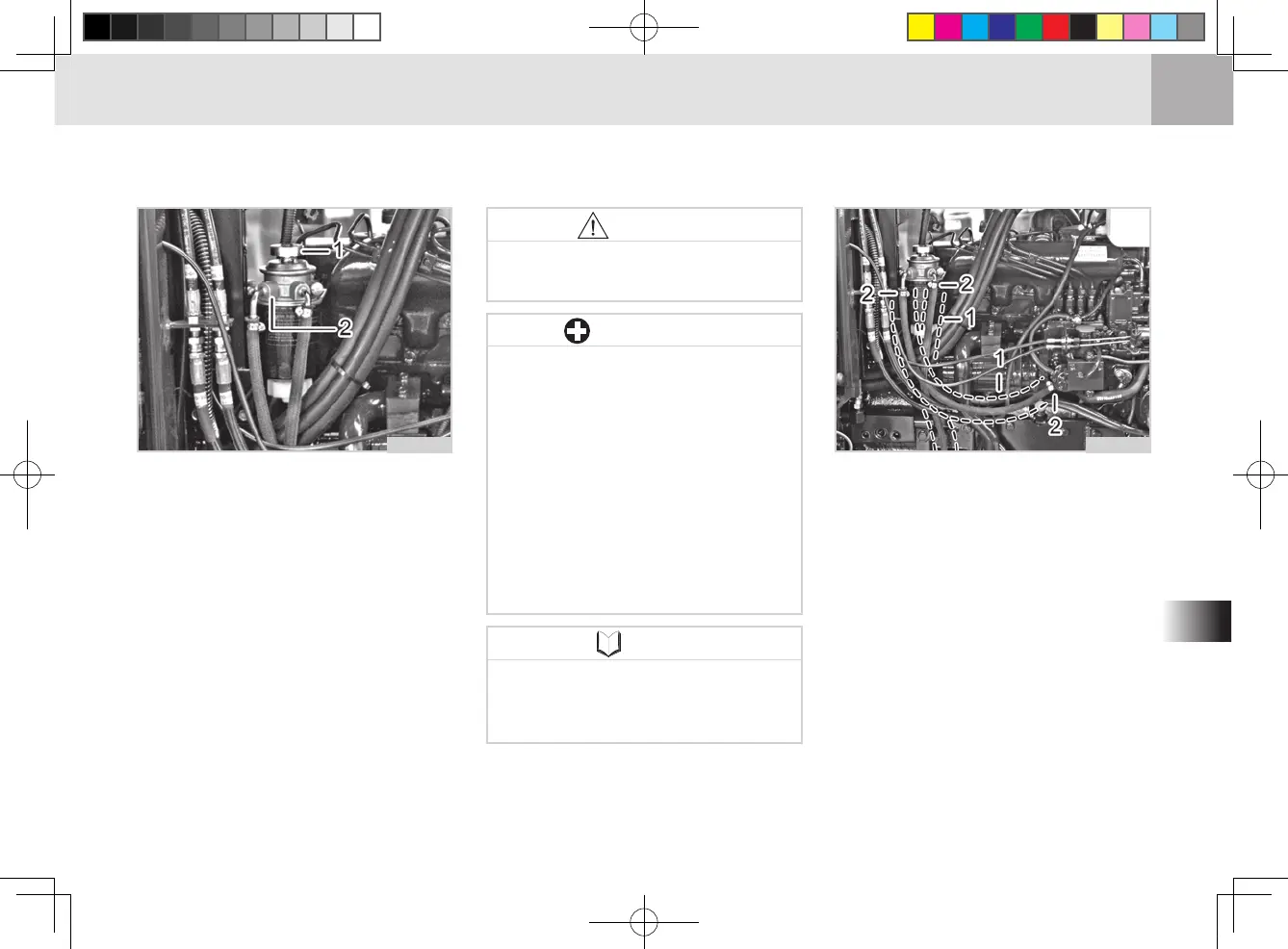

(1) Fuel Pipe (2) Tightening Band

CHECKING FUEL LINES (U)

Although checking the fuel pipe con-

nection is recommended every 100

service hours, it should be done ev-

ery 6 months if operation does not

exceed 100 hours in 6 months.

1. If the hose clamps are loose, apply

a slight coat of lubricant onto the

threads and securely tighten it.

2. The fuel pipe is made of rubber

and ages regardless of period of

service. Change the fuel pipe to-

gether with the hose clamps every

two years and securely tighten.

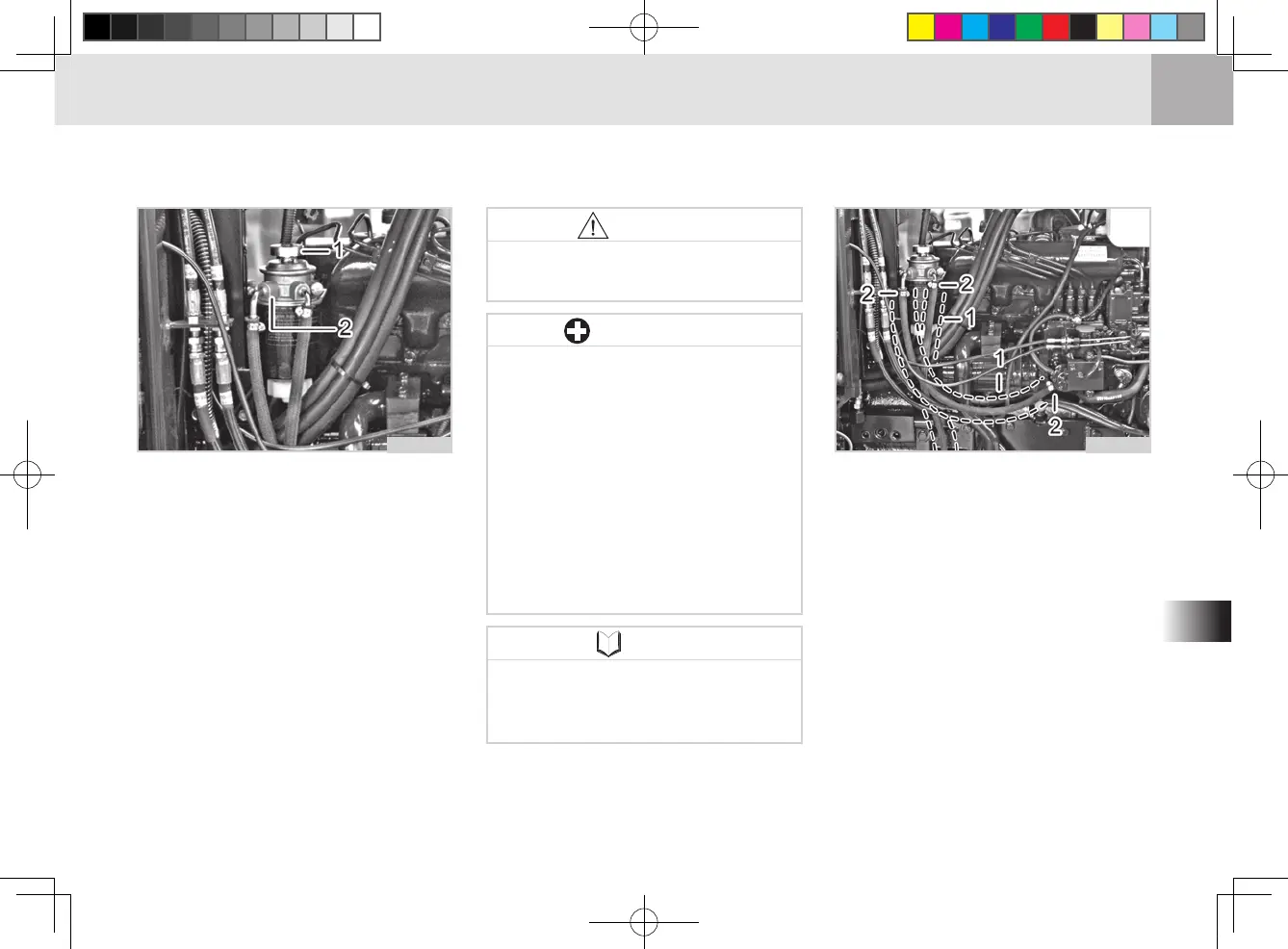

BLEEDING BRAKE FLUID LINE (T2)

(1) Drive Pump (2) Air Plug

1. Open the air plug of the fuel lter

and operate the drive pump to

bleed the fuel line.

2. When there is no more air bubbles

in fuel flown out through the air

plug, the fuel line is fully bled.

Then, close the air plug.

M55O7B9A M55O7C1A

Never bleed the fuel system

while the engine is hot.

•

CAUTION

After bleeding, fuel without air

bubbles is ltered by the fuel

lter and is transferred to the

fuel injection pump. Maintain

the proper fuel level in the fuel

tank before the fuel tank be-

comes empty. If all fuel is com-

pletely consumed in a Diesel

engine, fuel should be added

to the fuel tank and then the

fuel system should be bled.

•

IMPORTANT

If the engine cannot be started

even after bleeding the fuel sys-

tem, contact your local Dealer.

•

NOTE

Loading...

Loading...