3. If the fuel pipes and hose clamps

are found damaged or deterio-

rated earlier than two years, then

change them immediately.

4. Af t e r th e fu e l pi p e an d ho s e

clamps have been changed, bleed

the fuel system.

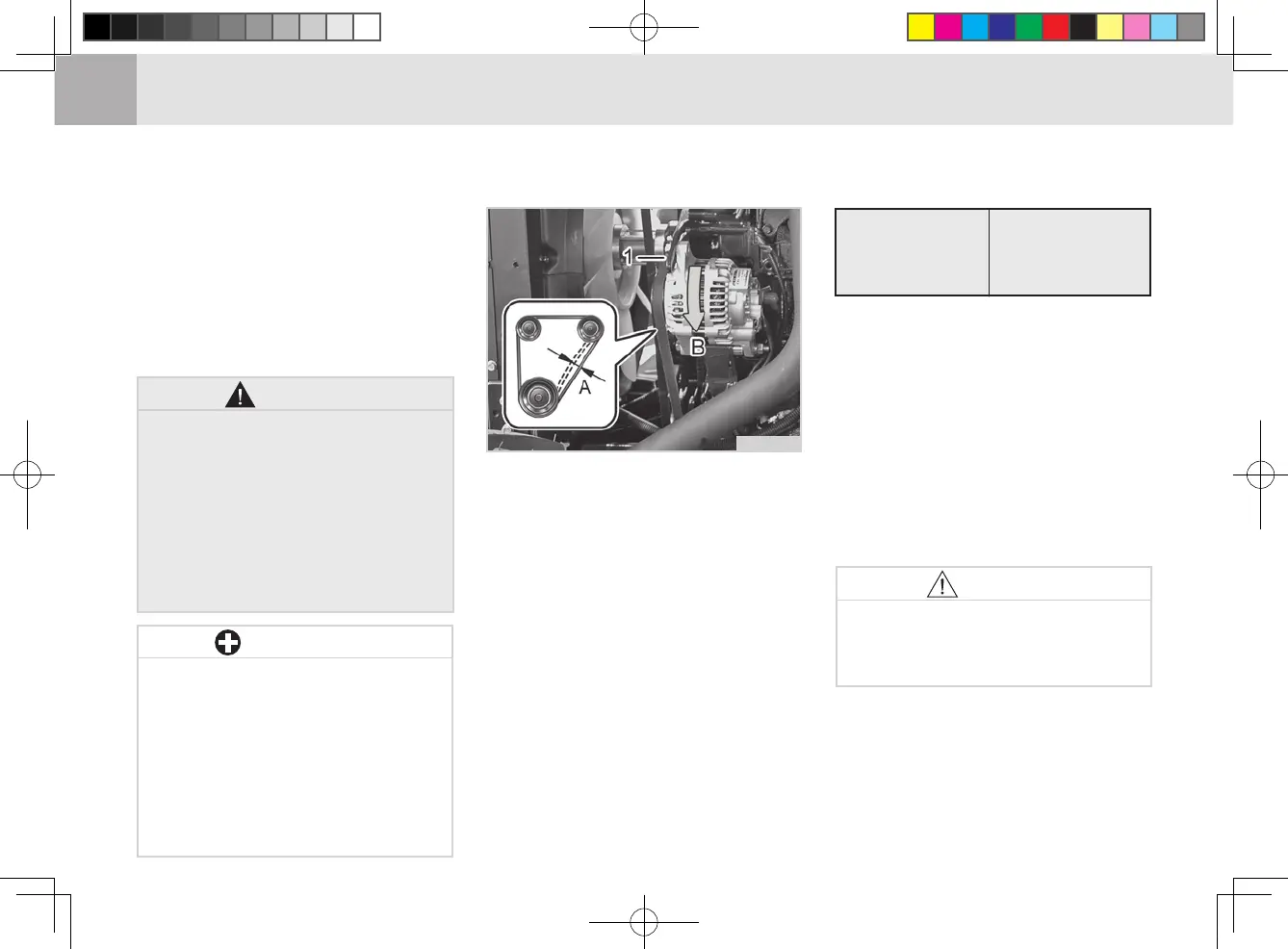

(1) Adjusting Bolt

(A) Adjusting Belt Tension (B) Pull

ADJUSTING FAN BELT TENSION (V)

In order to extend the fan belt’s life-

time, the tension of the belt should

be correctly adjusted if it slips. The

belt tension should be inspected

regularly according to the following

procedure:

1. Stop the engine and apply the

parking brake.

2. Open the hood.

3. Apply moderate thumb pressure

to the belt (A) between the crank-

shaft pulley and alternator pulley

to check for tension.

M55O779A

To avoid personal injury:

Be sure to stop the engine be-

fore checking belt tension.

•

CAUTION

Stop the engine when check-

ing the items above.

The fuel pipes are subject to

wear and aging. Failure to per-

form periodic inspections may

lead to a fuel leak. Fuel leaking

on a hot engine could cause a

re.

•

•

WARNING

When changing fuel pipes, be

careful not to allow dust or dirt

to enter the fuel system. Con-

taminations in the fuel system

could damage the fuel system

or injection pump. Pay extra

caution to the fuel pump to

prevent dust from entering it.

•

IMPORTANT

Belt deection for

proper fan belt

tension (A)

0.39 ~ 0.47 in.

(10 ~12 mm)

4. If tension is incorrect, loosen the

alternator mounting bolt and hinge

bolt. Pull the alternator outward

using a pry bar to reach the proper

belt tension.

5. Be sure to retighten the alternator

mounting bolt and hinge bolt se-

curely after adjusting belt tension.

6. Replace the fan belt if it is dam-

aged, cracked or worn.

Loading...

Loading...