4.2 Parameter setting

A default parameter set is loaded into your servo amplifier by the manufacturer. This contains valid

and safe parameters for the current and speed controllers.

A database for motor parameters is stored in the servo amplifier. During setup you must select the

data set for the motor that is connected and store it in the servo amplifier. For most applications

these settings will already provide good to very good control loop characteristics.

An exact description of all parameters and the possibilities for optimizing the control loop character

-

istics can be found in the manual “Setup Software DRIVE.EXE”.

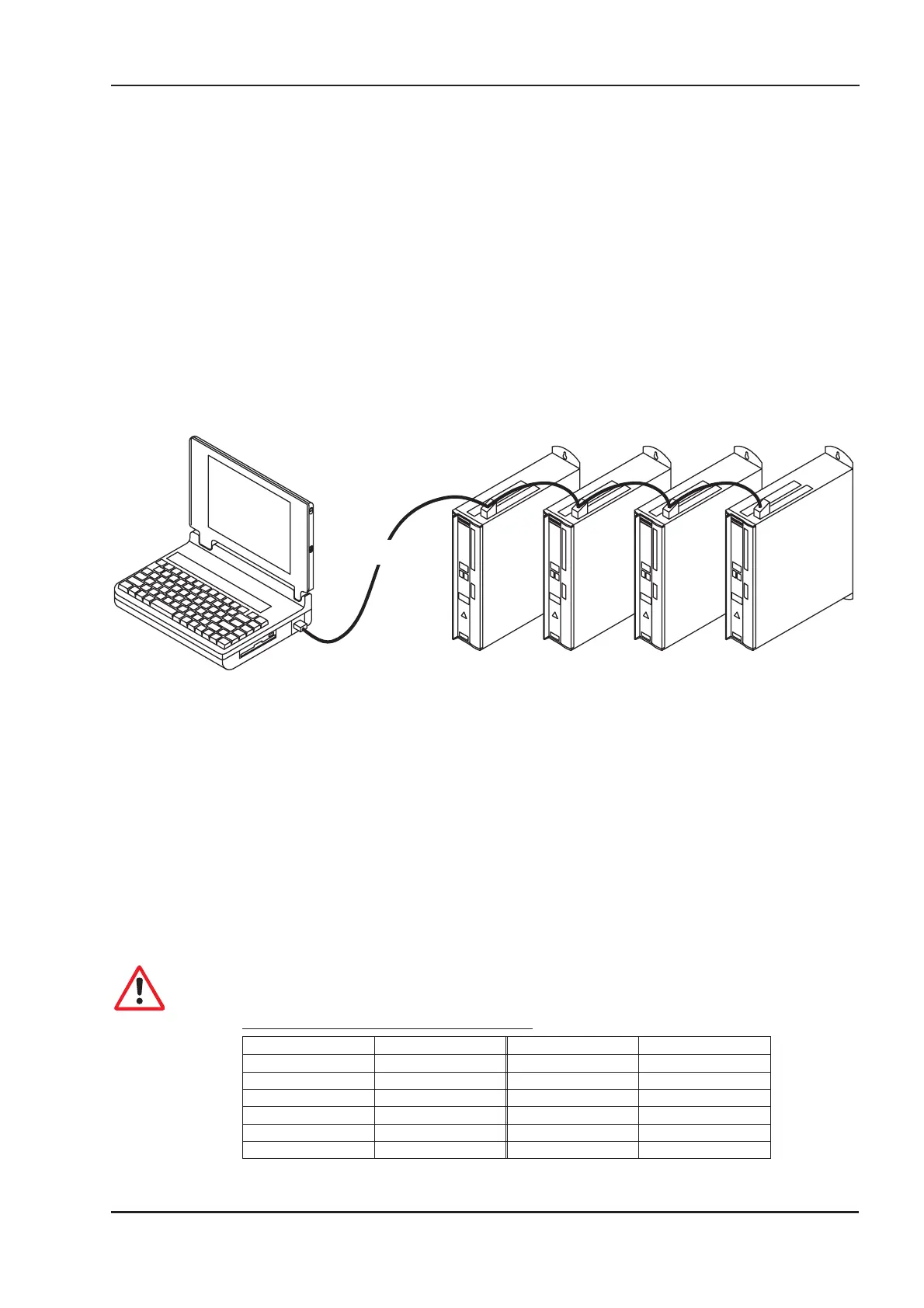

4.2.1 Multi-axis systems

Using a special multilink cable, you can connect up to six servo amplifiers together and to your PC :

Cable type -SR6Y- (for 4 amplifiers) or -SR6Y6- (for 6 amplifiers)

With the PC connected to just one servo amplifier you can now use the setup software to select all

four / six amplifiers through the preset station addresses and set up the parameters.

4.2.1.1 Node address for CAN-bus

During setup it makes sense to preset the station addresses for the individual amplifiers and the

baud rate for communication by means of the keypad on the front panel (ð p.59).

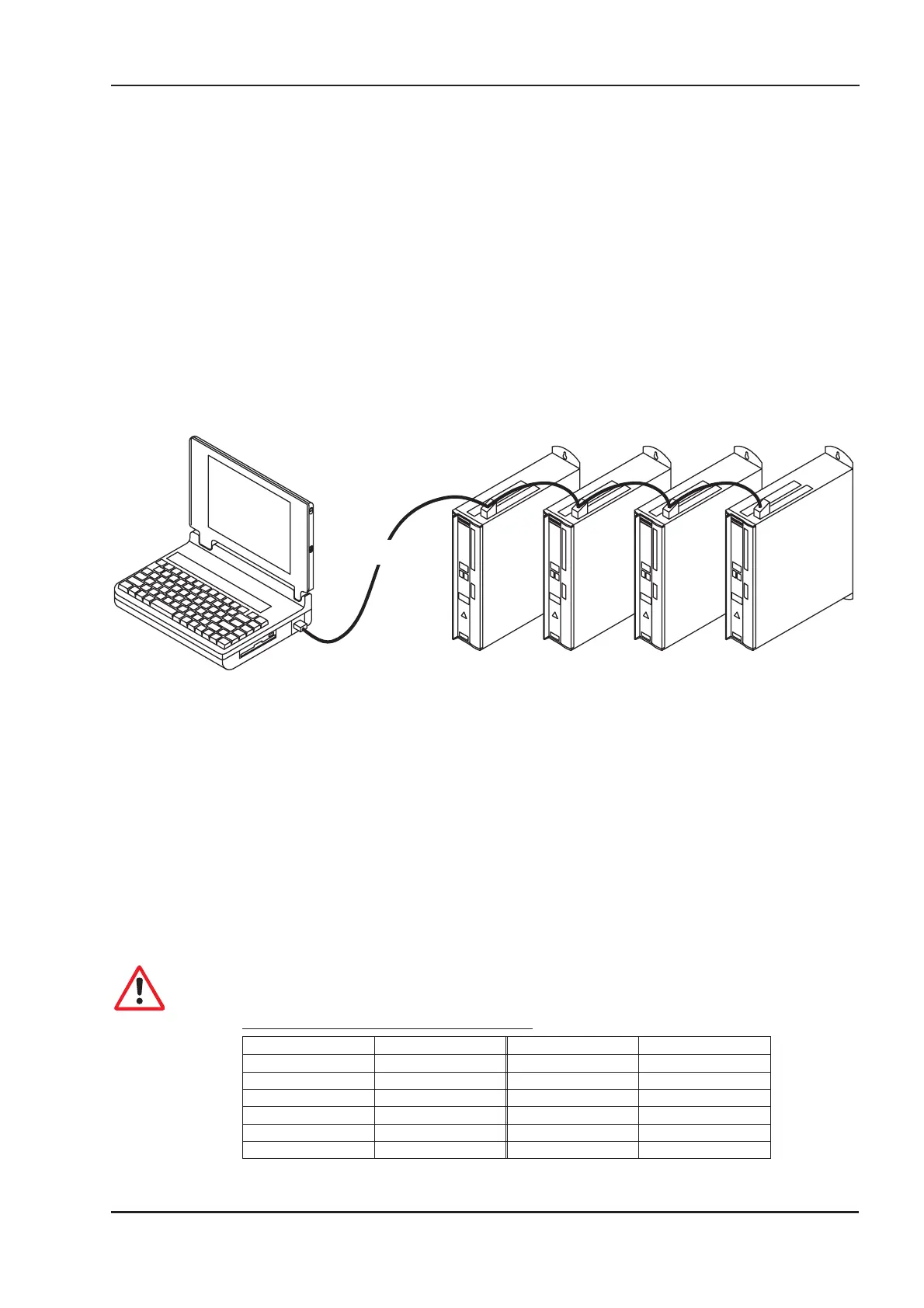

4.2.1.2 Baud rate for CAN-bus

After changing the station address and baud rate you must turn the 24V auxiliary supply of

the servo amplifier off and on again.

Coding of the baud rate in the LED display :

Coding Baud rate in kbit/s Coding Baud rate in kbit/s

0 10 5 250

1 20 6 333

2 50 7 500

3 100 8 666

4 125 9 800

10 1000

SERVOSTAR

®

601...620 Installation Manual 57

Kollmorgen 03/04 Setup

PC

Add.:

01

Add.:

02

Add.:

03

Add.:

04

COMx

RS232

Cable -SR6Y-

X6

PC/CAN

X6

CAN

X6

CAN

X6

CAN

Baud rate identical for all amplifiers,

see table below

Loading...

Loading...