8400 motec | Software Manual

Basic functions

Holding brake control

182 L Firmware ≤ 02.00 - DMS 2.1 EN - 03/2011

8.2.1.2 Functional settings

In C02582

, the following functional settings for holding brake control can be made in bit-

coded form:

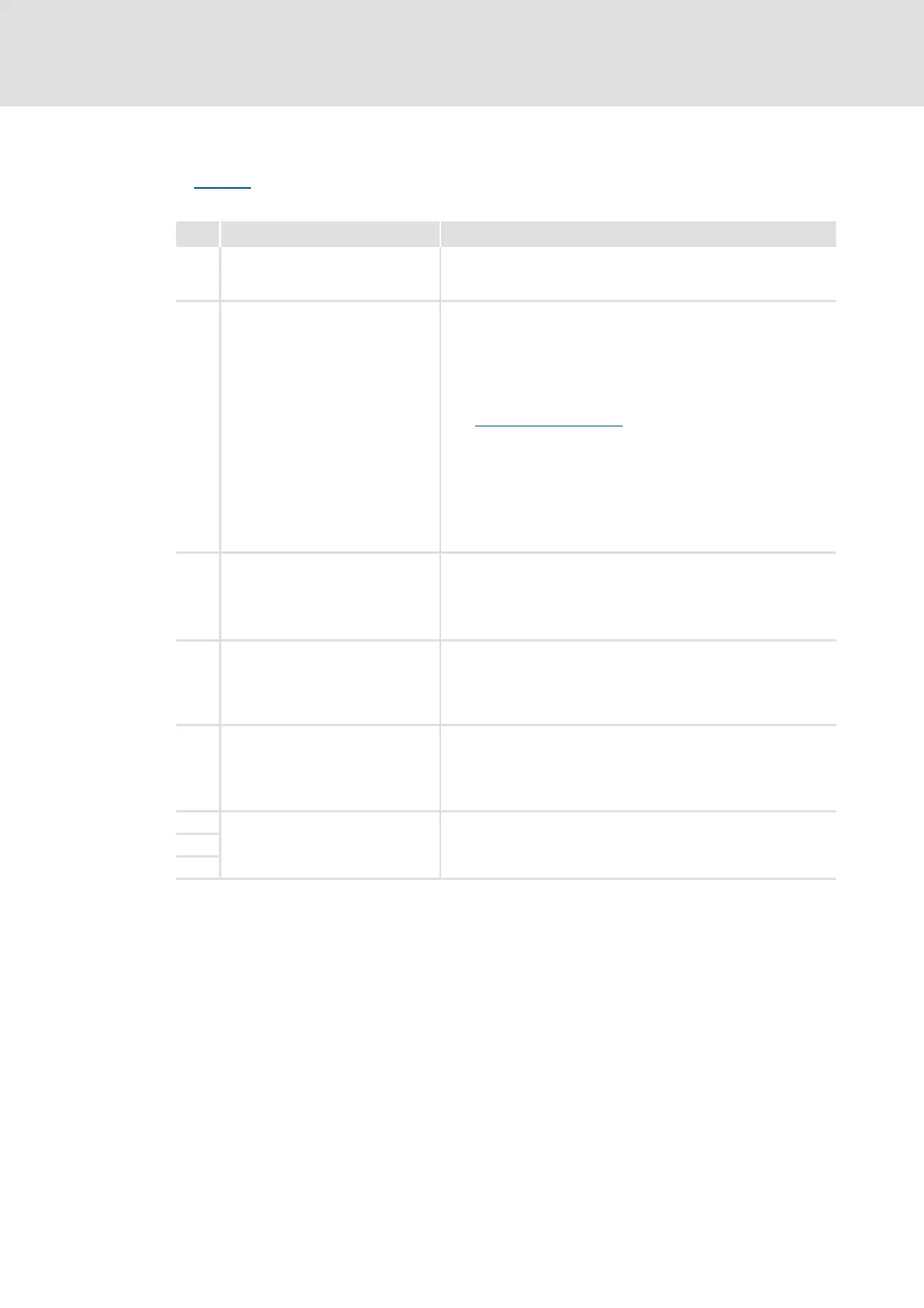

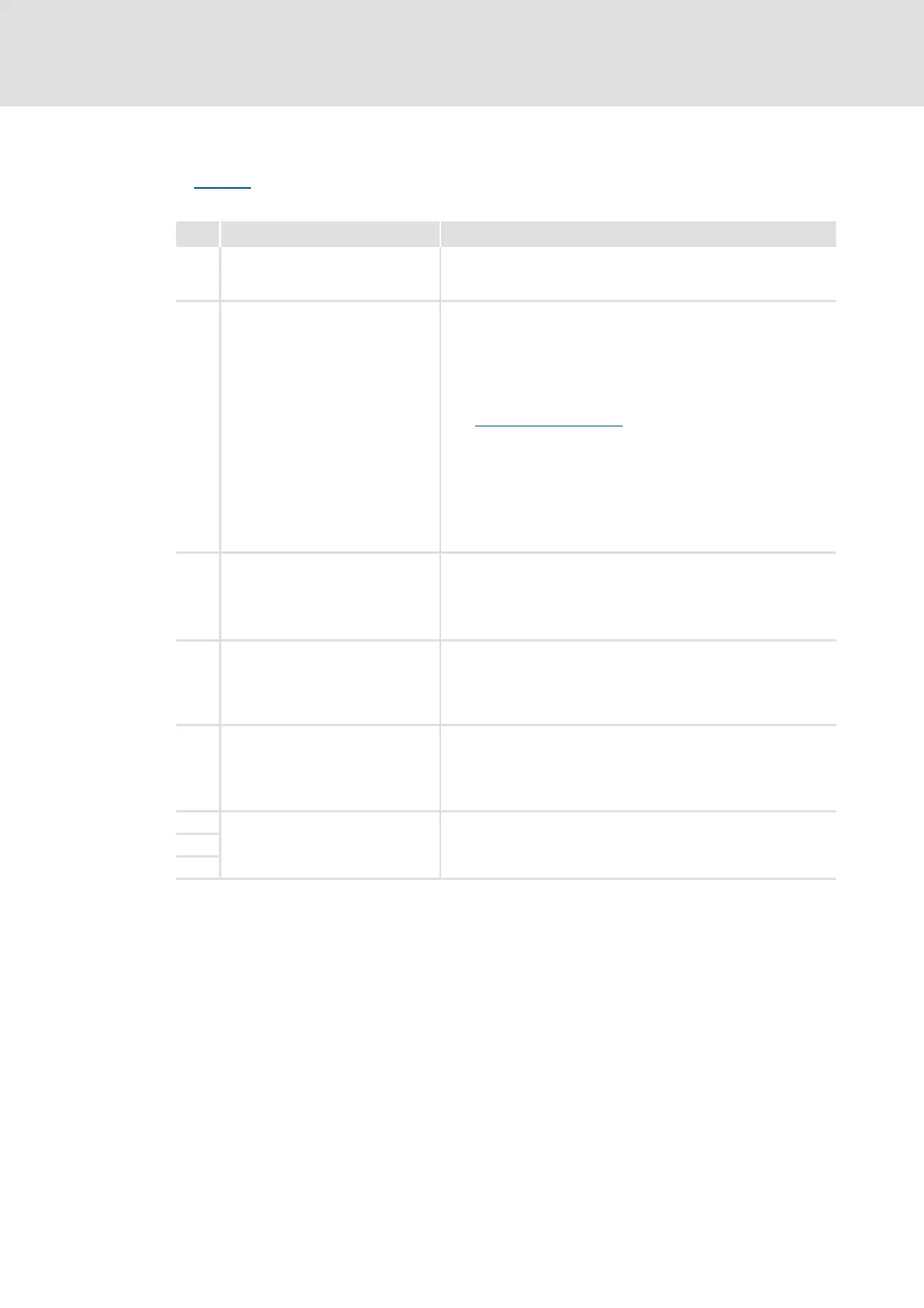

Bit Option Info

Bit 0 Control inverted Activation of inverted control

•"1" ≡ Inverted logic of the trigger signal bBrkReleaseOut for

triggering the power output (terminals BR1 and BR2).

Bit 1 nAct < nMin at CInh Brake response in case of pulse inhibit

•"1" ≡ With pulse inhibit, the actual speed value is monitored. The

holding brake is applied when the actual speed reaches the

"Application" threshold value.

Note:

• Function only possible if speed feedback via the digital input

terminals DI1/DI2 is available.

Encoder/feedback system

• This function is only active if bit 3 (horizontal/winding

technology) has been set. The function is used in order that, in

case of controller inhibit, the holding brake of a drive with

horizontal traverse path does not wear out when rotating.

• With a vertical movement (bit 3 = 0), this function is not active.

Especially in the case of hoist drives, immediate engagement of

the brake is absolutely necessary for safety reasons if the pulse

inhibit function of the drive controller has been activated!

Bit 2 Inverted feedforward control Direction of feedforward control with vertical/hoist technology:

•"0" ≡ Positive direction

•"1" ≡ Negative direction

Note:

• Reversal (Ccw) is then considered.

Bit 3 Horizontal/winding technology Direction of the axis

•"0" ≡ The direction of the axis is vertical. The gravitational

acceleration does not cause any movement.

•"1" ≡ The direction of the axis is horizontal or rotary. The

gravitational acceleration does not cause any movement.

Bit 4 No premagnetisation From version 02.00.00

Deactivation of the 200 ms premagnetisation before releasing the

brake.

•"0" ≡ Premagnetisation in case of feedforward control.

•"1" ≡ No premagnetisation.

Bit 5 Reserved

Bit 6

Bit 7

Loading...

Loading...