Service Manual 157

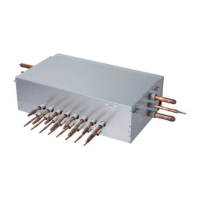

Function

• If power is on, it will operate to charge capacitor on controller and power relay will operate after about

2~5sec.

• The final operating freq. of comp. is set to sum of operating indoor unit capacities.

• Hot gas and Liquid injection control by solenoid valve

• It will be changed the drive voltage of comp. according to operating frequency.

• It is only operated in the heating operation mode except defrosting operation.

• High speed/Low speed

Outdoor Unit

Power relay control

Comp. Freq. control

Overheatng and over current Protection(IPM)

Bypass control

V/F control

Total current control (over current protection)

4 way valve control

Outdoor fan motor control

Discharge pipe temperature control

LEV Control

Discharge Pressure control

Suction Pressure control

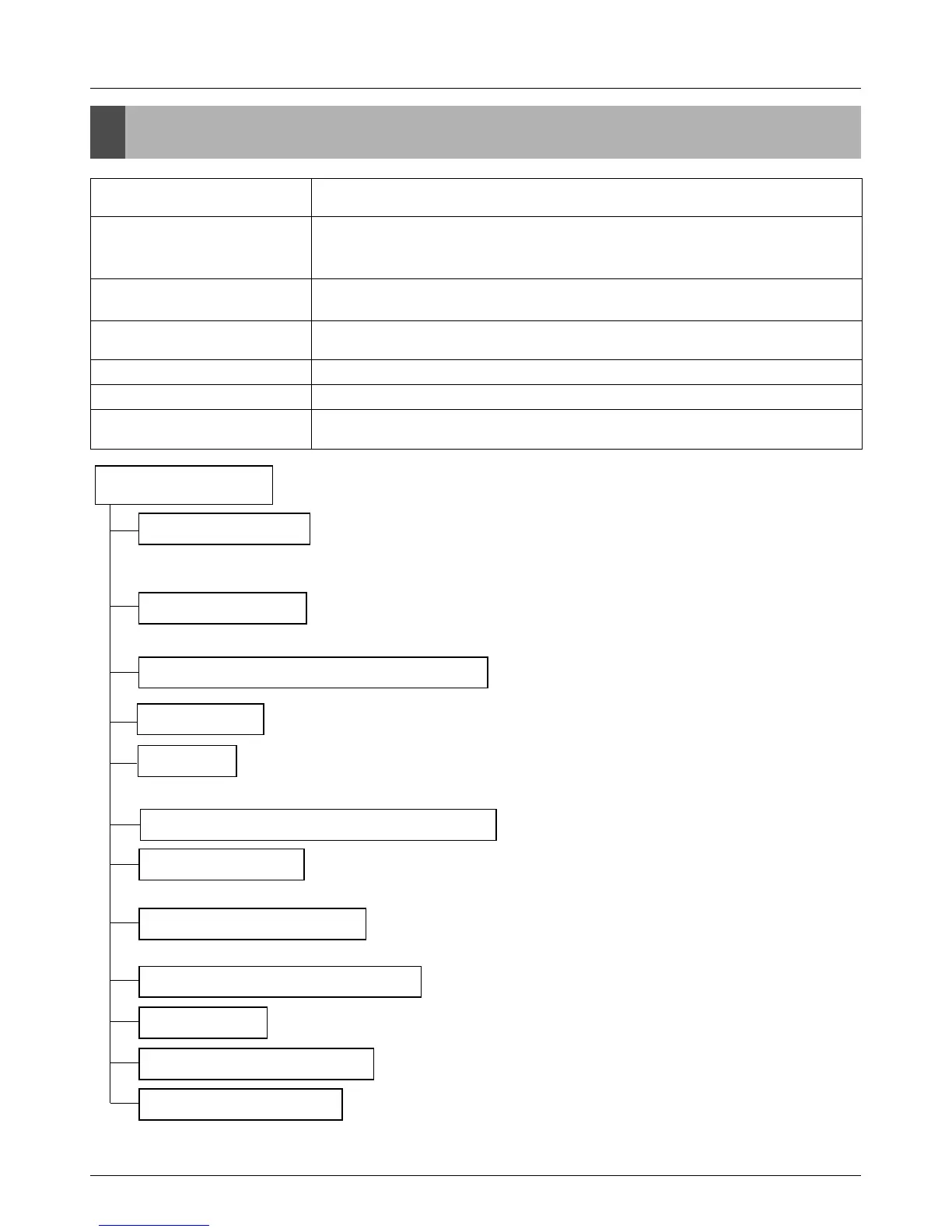

Scroll compressor that operates on 30~120Hz by inverter drive enables

capacity control.

The oil separator is a device that collects the discharged oil from the

Compressor. The collected oil is constantly recycled to the compressor via

capillary tube.

High pressure sensor for sensing the operating status of the indoor by refriger-

ant pressure which senses discharge pressure.

Low pressure sensor for sensing the operating status of the indoor by refriger-

ant pressure which senses suction pressure.

Valve is open by low pressure safety control when pressure drops.

Controls liquid injection in order to prevent overheating.

Linear expansion valve is controlled by micro controller when heating.

When cooling linear expansion valve is fully opened.

Inverter Compressor

Oil separator

High Pressure Sensor

Low Pressure Sensor

Hot gas Solenoid valve

Liquid Injection Solenoid valve

Linear Expansion Valve(LEV)

2. Function

Loading...

Loading...