215585 11 Revision A

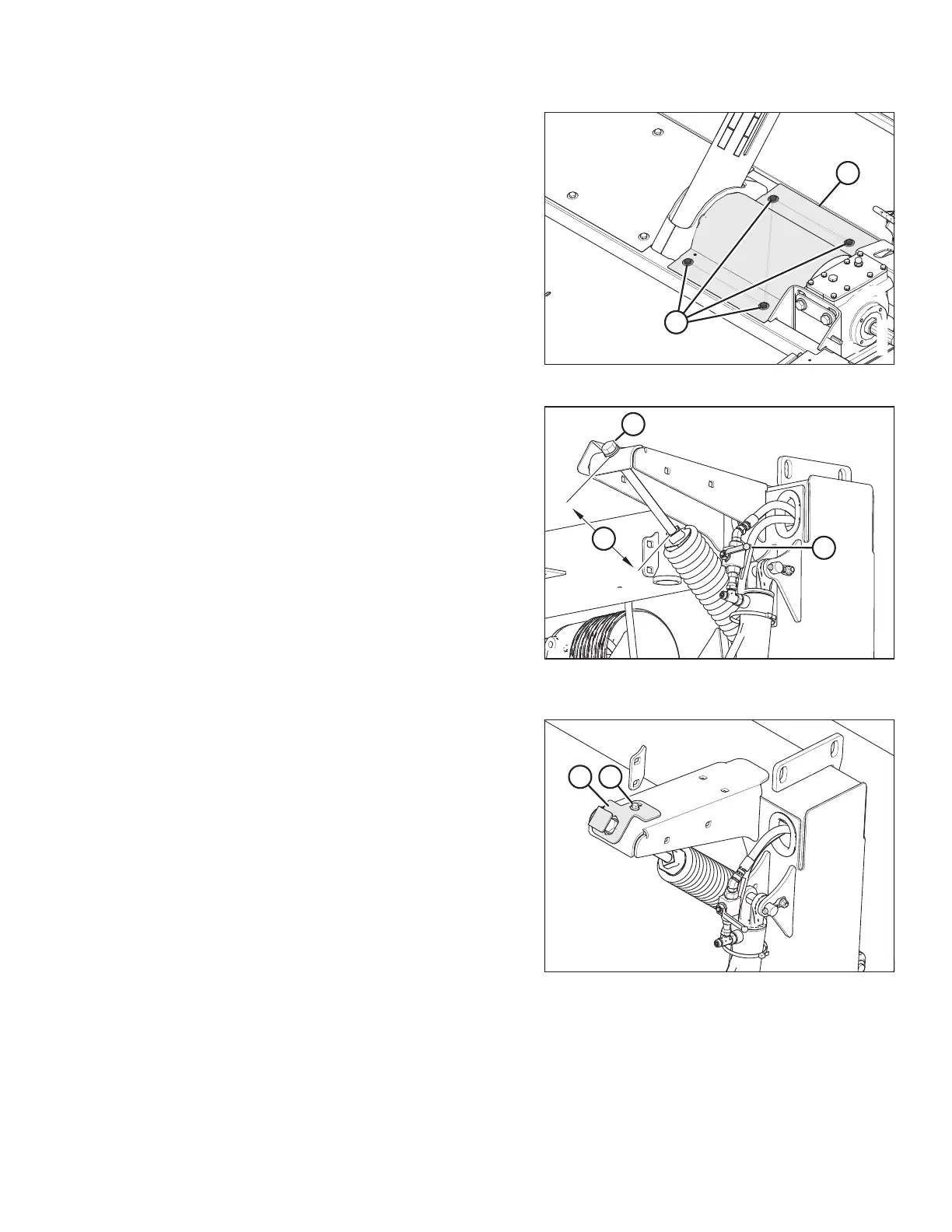

Figure 3.6: Top Shield – Left of Center-Link

8. Install top shield (B) and secure with four M10 hex head

bolts (A) and flat washers. Torque to 28.5 Nm (21 lbf·ft).

NOTE:

If transport is also being installed, leave bolts (A) loose.

These bolts will be tightened when installing the lighting

harness.

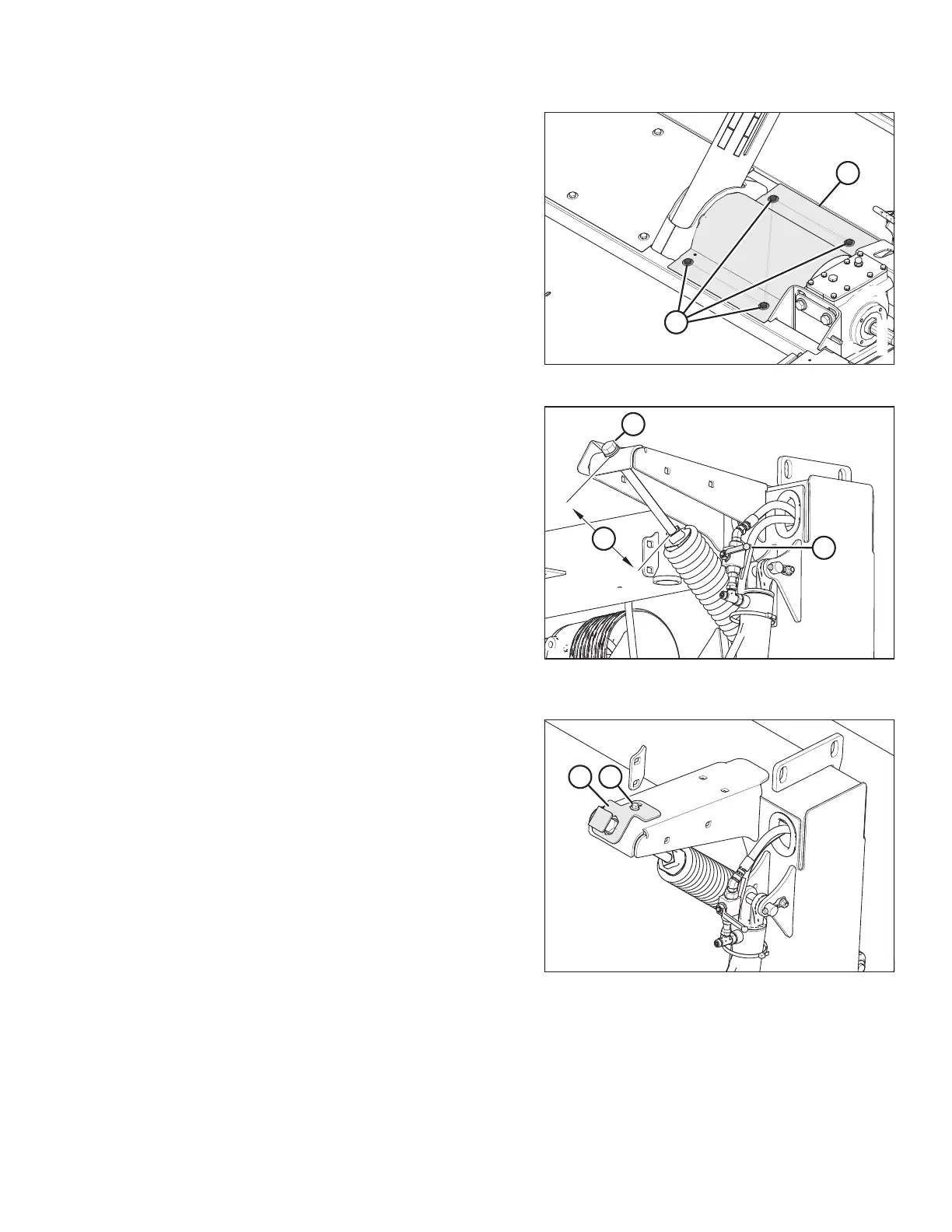

Figure 3.7: Lift Cylinder Lock-Out Valve and

Adjuster Bolt

9. Close lock-out valve (A) on each rotary disc pull-type lift

cylinder by turning the handle to the horizontal position.

Repeat on opposite side.

10. Turn adjuster bolt (B) to set dimension (C) to 130 mm

(5 1/8 in.). Repeat on opposite side.

• Turn bolt clockwise (towards spring) to increase float

• Turn bolt counterclockwise (away from spring) to

decrease float

Figure 3.8: Adjuster Bolt Cover Plate

11. Reposition cover plate (A) over float spring adjuster bolt as

shown. Secure cover plate (A) by tightening bolt (B). Repeat

on opposite side.

ASSEMBLING THE ROTARY DISC PULL-TYPE – WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT

Loading...

Loading...