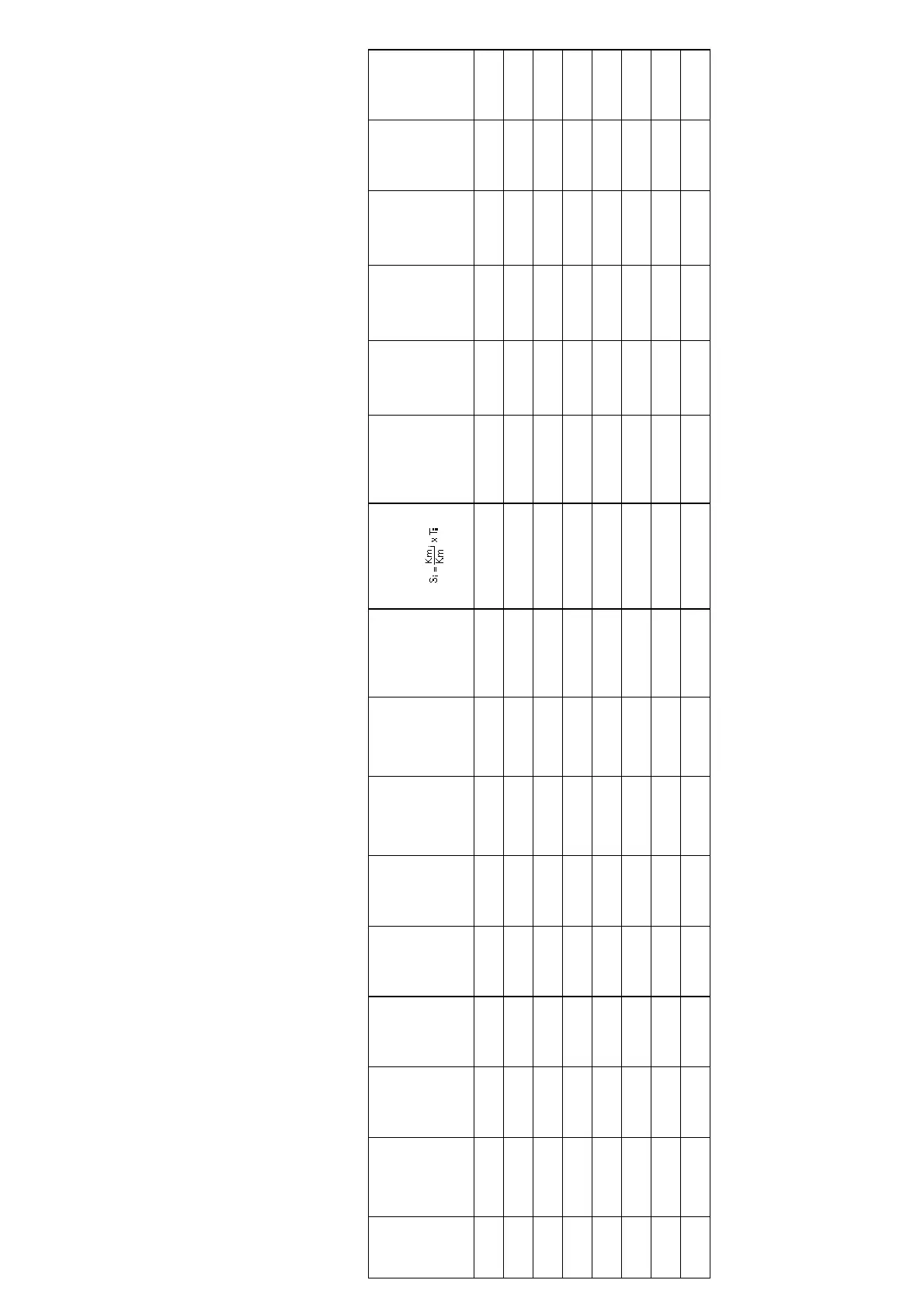

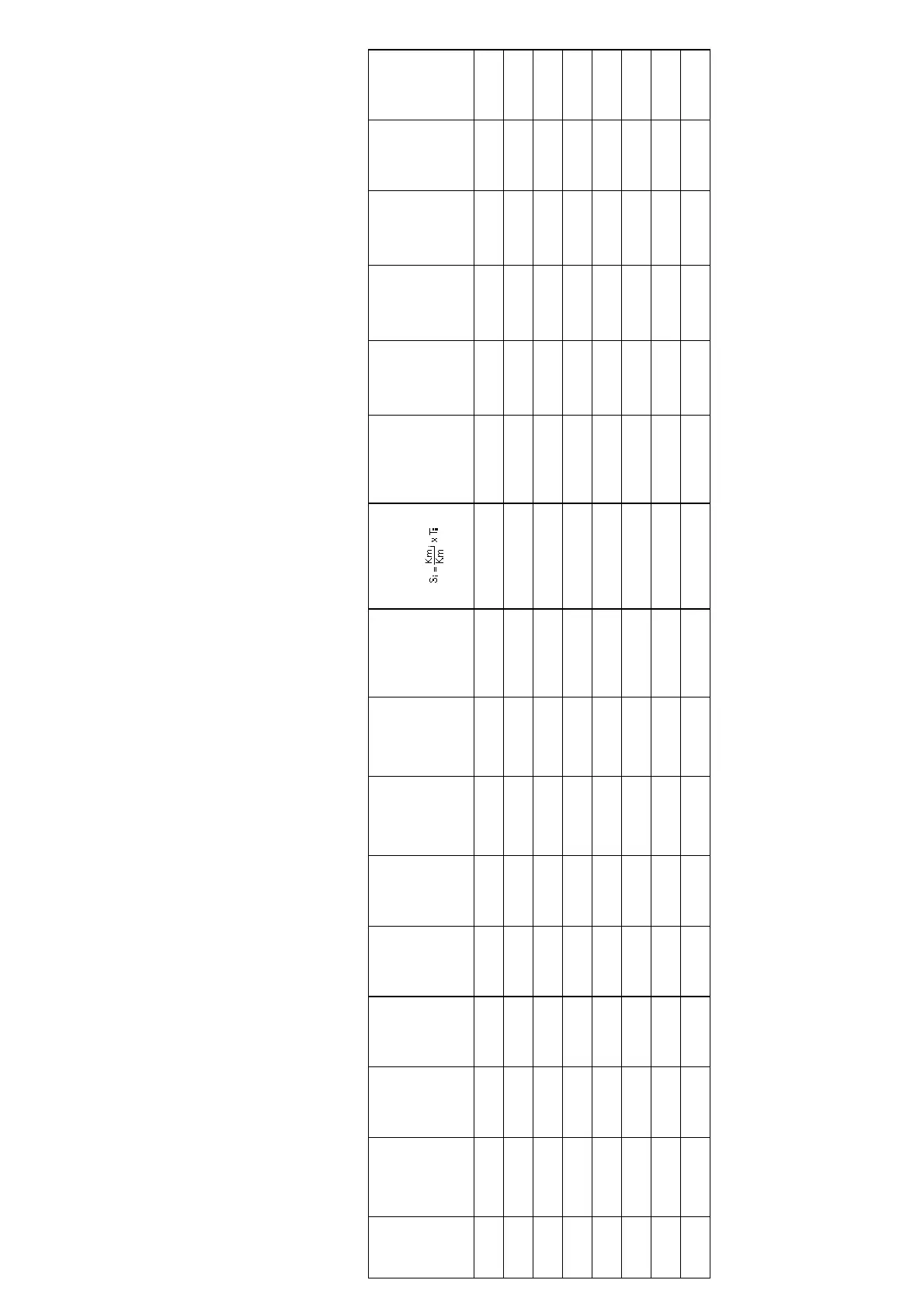

Table to determine the remaining theoretical service life on winch no. ..........

Crane type: ........................

Work no.: ........................

First put into operation on: ........................

Winch serial number in accordance with the

model plate: ........................

Last general overhaul performed on: ........................

Winch design data (see operating manual):

Engine group: ........................

Load spectrum: ........................

Load spectrum factor: ........................

Theoretical service life: ........................

IMPORTANT:

A general overhaul must be performed every 10 years.

For alternative provision, refer to section 5.4.2, p. 5 - 25.

General overhaul performed on..................................

Inspec-

tion inter-

val no.

(max.

1 year)

Date of first

commission-

ing/date of

inspection

Operating

conditions

since the

last

inspection

Factor of

the load

spectrum

Operating

hours of

the entire

crane

Operating

hours of

the super-

structure

Operating

hours of the

superstruc-

ture since

the last in-

spection

Operating

hours of the

winch

Winch

operating

hours since

the last

inspection

Used proportion

of theoretical

service life D:

Remaining

theoretical

service life

D

i

= D

i-1

- S

i

Name of the

expert

Signature Comment Name of

the

approved

inspector

Signature

“i” Km

i

[h] [h] [h] [h] [h] [h] [h]

(*)

S

i

= Used proportion of theoretical service life since the last inspection

D

i

= Remaining theoretical service life

D

i - 1

= Remaining theoretical service life after the previous inspection

Km = Factor of the load spectrum used to calculate the winch.

This factor is given in the operating manual.

Km

i

= Factor of the load spectrum in the inspection interval “i” according to section 2.1

T

i

= Effective operating hours in the inspection interval “i” according to section 2.2

(*) Copy the last line of the previous page to the following page.

Loading...

Loading...