Maintenance overview

5.4 Measures required for winch monitoring

25.11.2016

Maintenance manual 3 302 364 en 5 - 23

GMK 4100L-1

Determining the

operating

conditions

(load spectrum)

The truck crane's load spectrum is divided into groups (see also ISO 4301/1,

FEM 1.001):

H

When determining the load spectrum, the existing rope pull is used as the

standard, i.e. under certain circumstances, the truck crane can be

supporting a small load, whereby the winch is actually supporting a heavy

load, e.g. due to insufficient reeving. Therefore, the following graphic

representation of the load spectrum refers to the winch's rope pulls.

s

Load

spectrum

class

Definition Proportions of the running

time

Factor of

the load-

spectrum

Km =

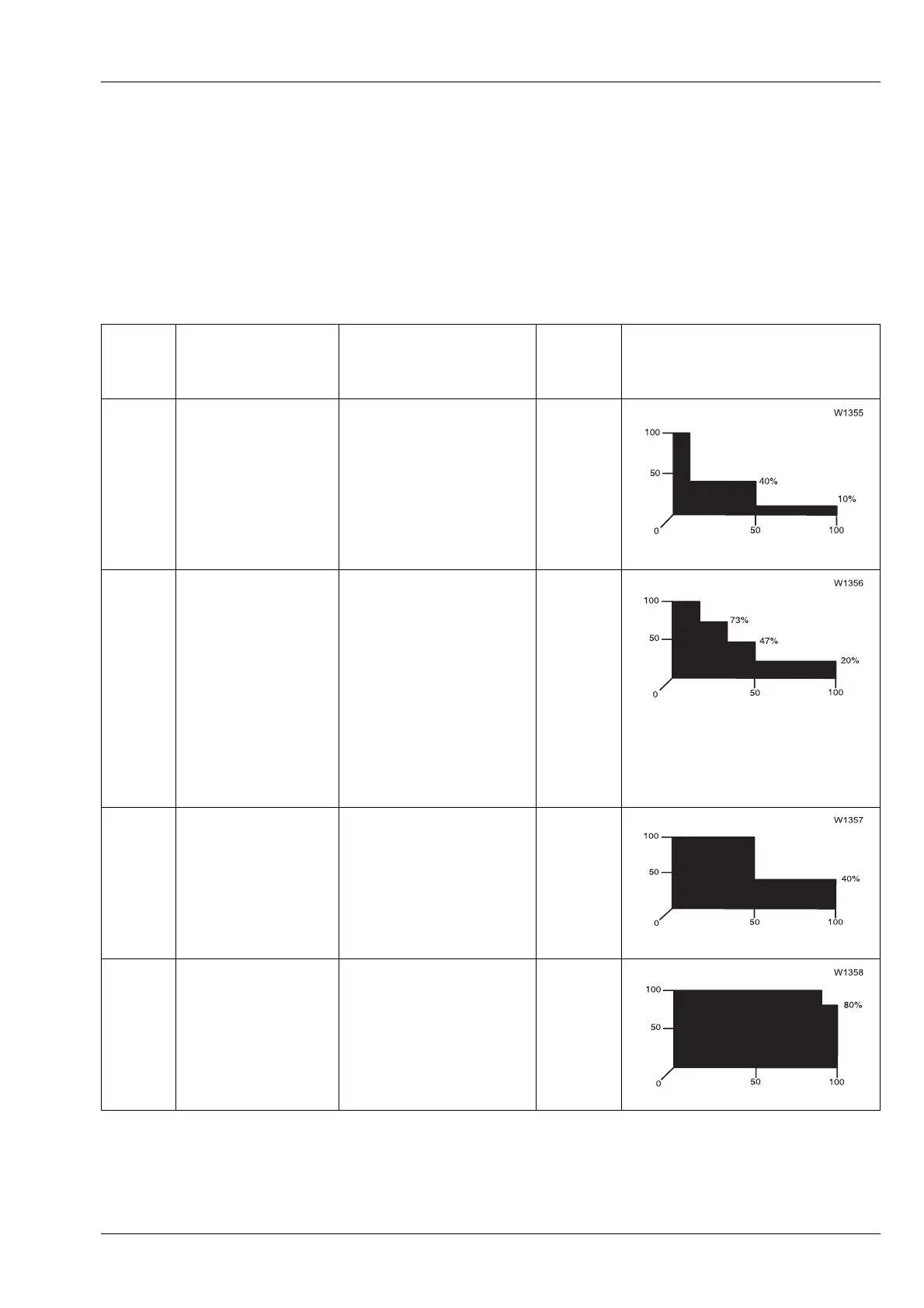

Graphic representation

Light

Q1

L1

Power units or parts

thereo

f that are su

bject

to high stress in

exceptional situations,

but which are generally

subject to only low

stress

10% of the running time with

greatest load

(dead load + 1/1

payload)

40% of the running time with

dead load

+ 1/3 payload

50% of the timing period with

dead load

only

0.125

Medium

Q2

L2

Power units or parts

thereof that are su

bject

to high stress quite

frequently, but which

are generally subject to

only low stress

1/6 of the running time with

greatest load

(dead load + 1/1

payload)

1/6 of the running time with

dead

load

+

2/3 payload

1/6 of the running time with

dead load

+

1/3 payload

50% of the timing period with

dead load

only

0.25

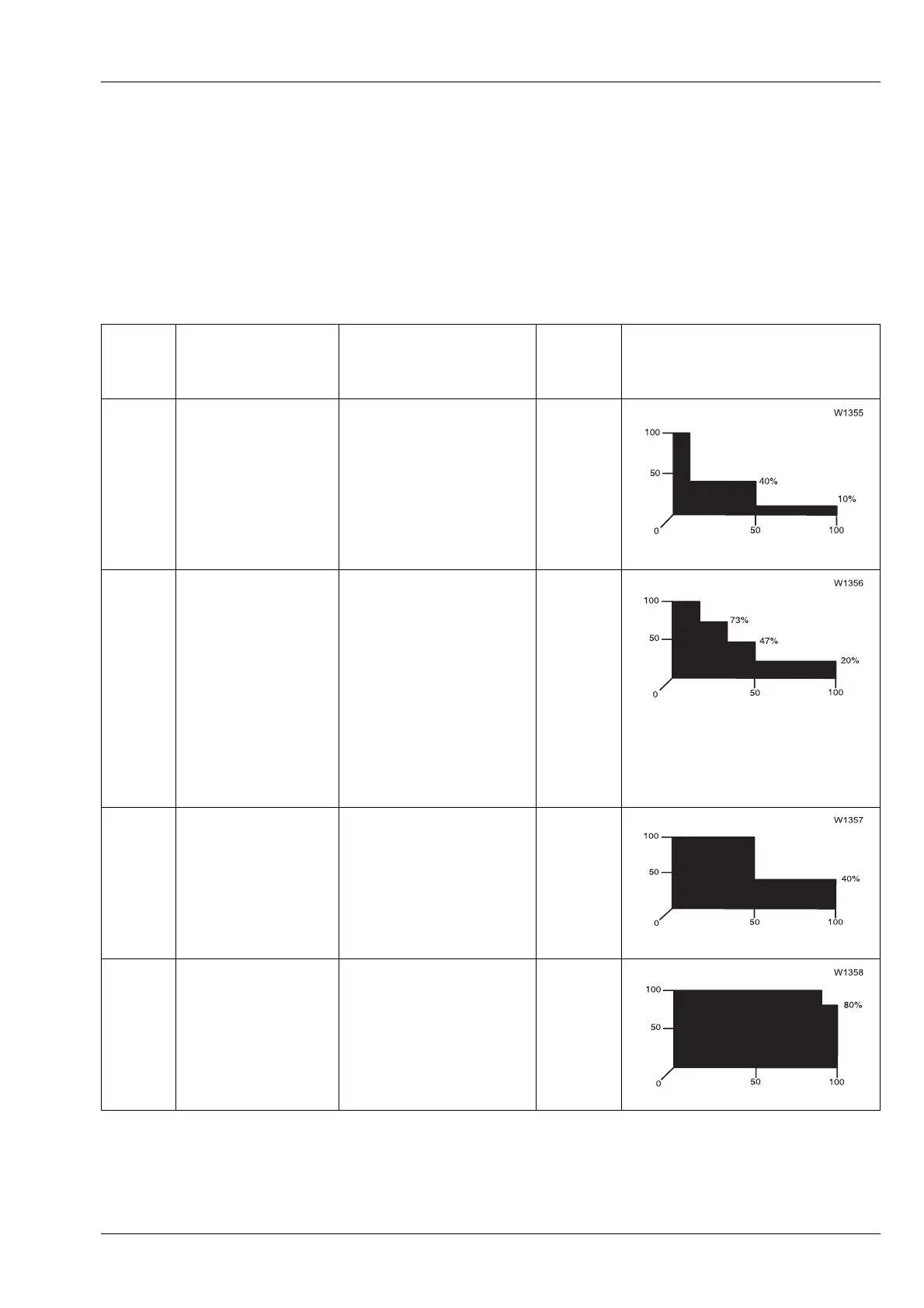

Heavy

Q3

L3

Power units or parts

thereo

f that are su

bject

to high stress frequently

and medium stress

continuously

50% of the running time with

greatest load

(dead load + 1/

1 payload)

50% of the timing period with

dead

load

only

0.5

Very

heavy

Q4

L4

Powe

r units or parts

thereo

f

that are regularly

subjected to the highest

stress from adjacent

stress sources

90% of the running time with

greatest load (dead load + 1/1

payload)

10% of the timing period with

dead load

only

1

Loading...

Loading...