6-4

Published 01-29-2014, Control # 496-00

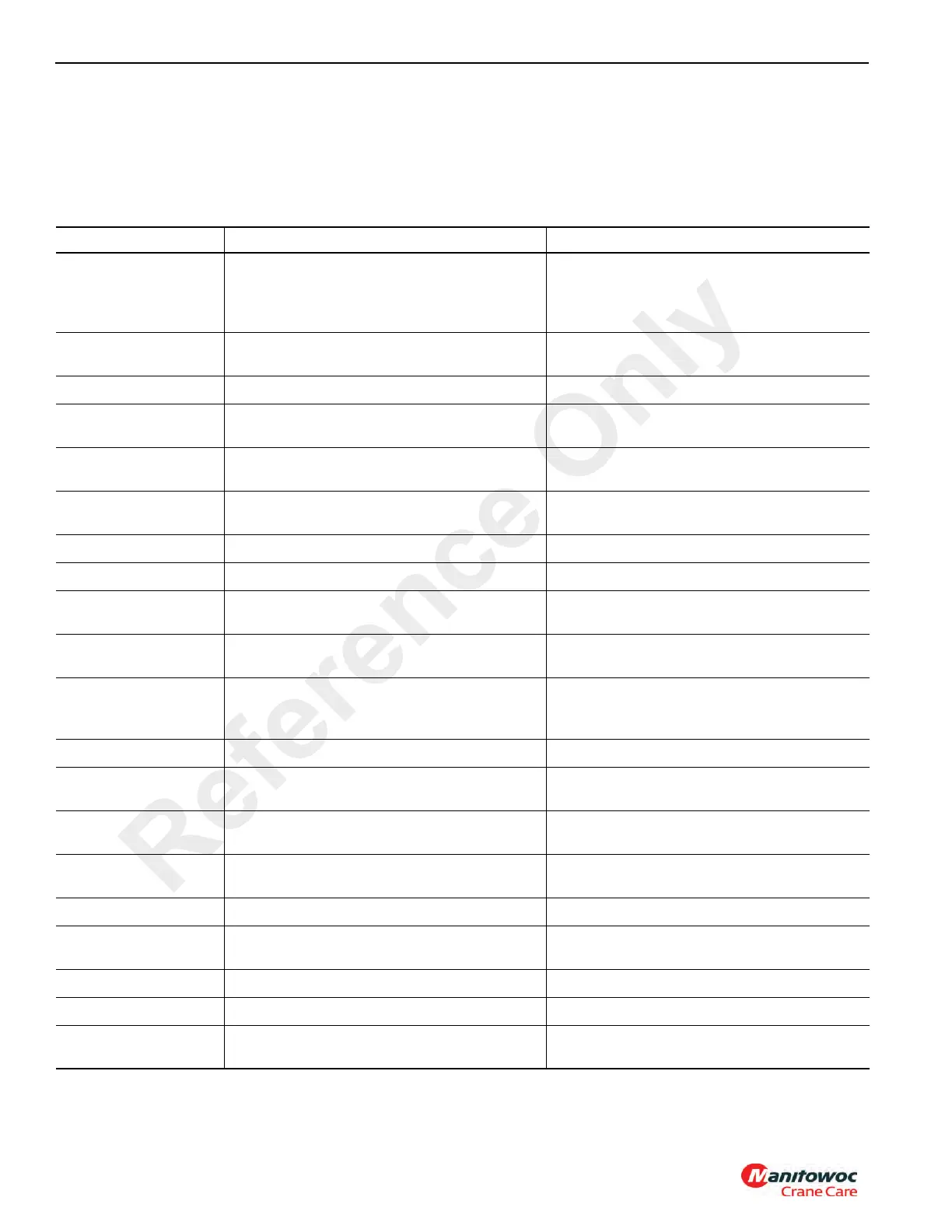

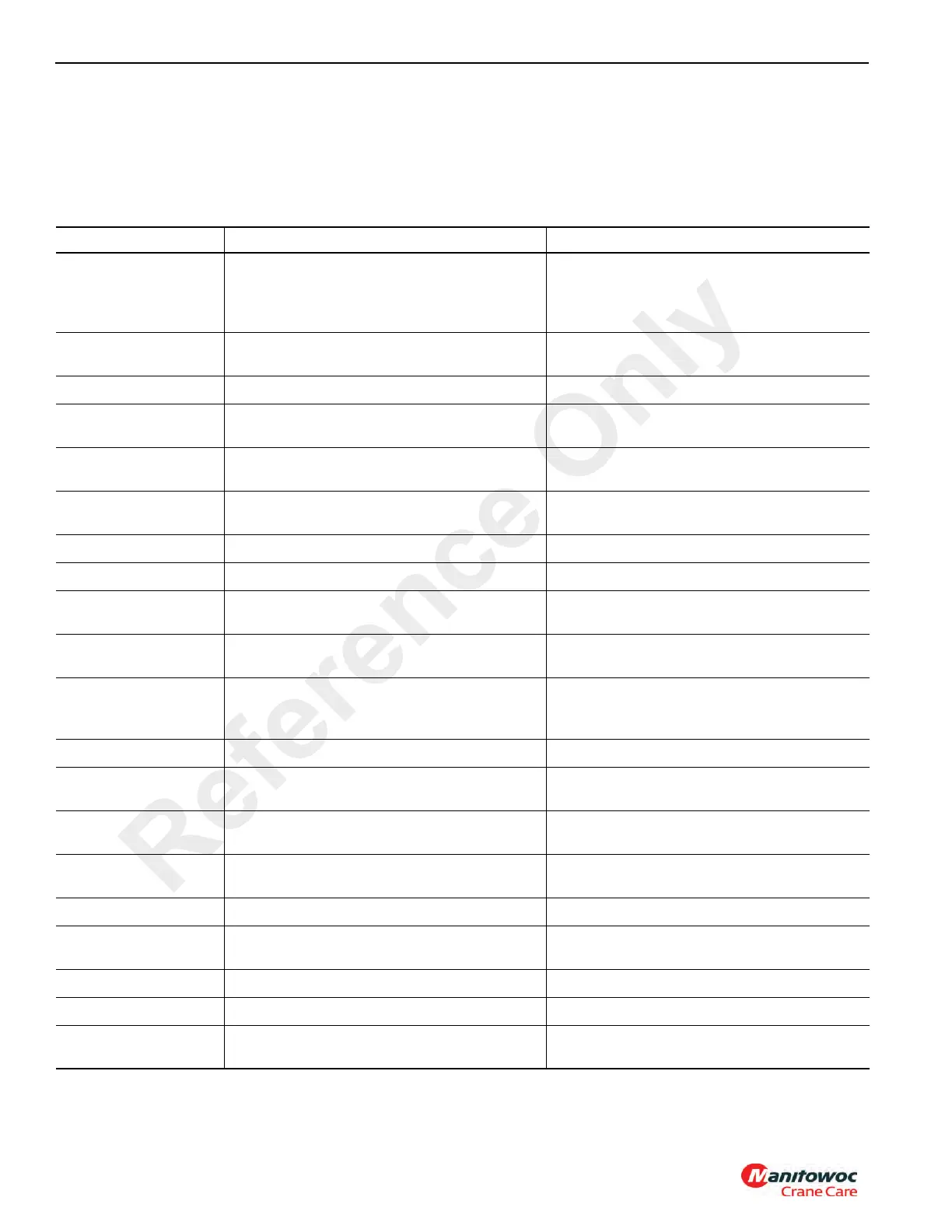

SWING SYSTEM TMS800E SERVICE MANUAL

MAINTENANCE

Troubleshooting

NOTE: CAN-bus service tool should be used to aid

troubleshooting. Service tool can be ordered

through the Manitowoc Technical Training Center.

Symptom Probable Cause Solution

1. Superstructure

swing operation

erratic in either

direction.

a. Low engine rpm a. Increase engine rpm to obtain smooth

swing operation.

b. Low hydraulic oil. b. Check for leaks. Repair any found.

Replenish hydraulic oil to proper level.

c. Damaged relief valve. c. Replace relief valve.

d. Swing brake dragging (not releasing

properly).

d. Readjust and/or replace necessary

parts.

e. Improper movement of control to

neutral.

e. Feather controls to neutral to maintain

smooth stopping action.

f. Insufficient lubricant on swing bearing. f. Lubricate bearing properly. Refer to

Section 9 - LUBRICATION.

g. Crane not level. g. Level crane using outriggers.

h. Damaged swing motor. h. Repair or replace swing motor.

i. Excessive overload. i. Reduce load. Refer to load capacity

chart.

j. Restricted or partly clogged hydraulic

hose or fittings.

j. Replace hose or fittings.

k. Pump cavitation in swing section. k. Tighten suction hose or replace any

damaged fitting. Check hydraulic tank

level.

l. Improperly torqued turntable bolts. l. Torque turntable bolts evenly.

m. Excessive preload on upper and lower

pinion shaft bearing.

m. Adjust as necessary.

n. Improperly torqued swing motor

attachment bolts.

n. Torque swing motor attachment bolts.

o. Malfunction of the swing box. o. Remove swing box and make

necessary repairs.

p. Worn or damaged pump. p. Repair or replace damaged pump.

q. Damaged swing directional control

valve.

q. Repair or replace swing directional

control valve.

r. Damaged swing pinion. r. Replace pinion.

s. Damaged turntable bearing. s. Replace turntable bearing.

t. Hydraulic p

r

essures and EEPROMS

not setup correctly.

t. See pressure setting procedure.

Reference Only

Loading...

Loading...