8-72

Published 01-29-2014, Control # 496-00

UNDERCARRIAGE TMS800E SERVICE MANUAL

Outrigger Stabilizer Cylinder Internal Leak Test

Use the following procedure to troubleshoot and diagnose an

internal leak, a leaking pilot operated check valve or a

thermal contraction on an outrigger stabilizer cylinder.

Checking Cylinder for Internal Piston Seal Leak

1. Fully extend and set the outriggers.

2. Remove the rod side cylinder hose from the suspected

leaking stabilizer cylinder (see Figure 8-78). Oil will flow

until the cavity in the cylinder port block empties. Once

the port block cavity empties, oil should stop flowing

from the rod side port.

Check for the following conditions:

a. If oil stops flowing

, the cylinder’s internal piston seal

is sealing properly.

b. If oil continues to flow

out the rod port, the cylinder’s

internal piston seal is leaking.

3. After determining the condition of the cylinders internal

piston seal, leave the rod side hose disconnected and

continue to test the pilot operated check valve.

Testing Pilot Operated Check Valve for Leakage

1. Fully extend and set the outriggers.

2. Remove the piston side cylinder hose from the

suspected leaking stabilizer cylinder (see Figure 8-78).

Oil will flow until the cavity in the cylinder port block

empties. Once the port block cavity empties, oil should

stop flowing from the piston side port.

a. If oil stops flowing

, the cylinder’s pilot operated

check valve is sealing properly.

b. If oil continues to flow

out the piston port, the

cylinder’s pilot operated check valve is leaking.

If oil flow is not noticed from either port, the cylinder and pilot

operated check valve are functioning properly, and any

cylinder contraction during normal operation can be

attributed to thermal contraction of the oil.

OUTRIGGER SYSTEM VALVES

Description

There are five valve assemblies responsible for controlling

the outrigger system, the outrigger selector valve, the front

and rear outrigger control manifolds, and the pilot operated

check valves.

NOTE: For a more detailed DESCRIPTION and

MAINTENANCE of the valves, refer to Valves,

page 2-22.

Pilot Operated Check Valve

The pilot operated check valves are located in the outrigger

stabilizer port blocks. The check valve provides two

functions; the first function is a holding valve, the second

function provides a thermal relief of the stabilizer.

Outrigger Selector Valve

The integrated outrigger is mounted on the center of carrier

frame in bearing area. The valve contains a 214 bar (3100

psi) relief valve and a two position two way solenoid valve

that is normally open by passing oil from the inlet port to the

tank port. The valve also contains a three position four way

DANGER

Perform the following procedures with the crane

positioned on a firm level surface with outriggers fully

extended and set, and the crane in the travel position.

Remove hoses from one cylinder at a time.

CAUTION

When performing step number 2, remove hose to adapter

connection slowly. Trapped pressure may exit between

the outrigger cylinder and the work port pilot operated

check valves in the outrigger selector valve.

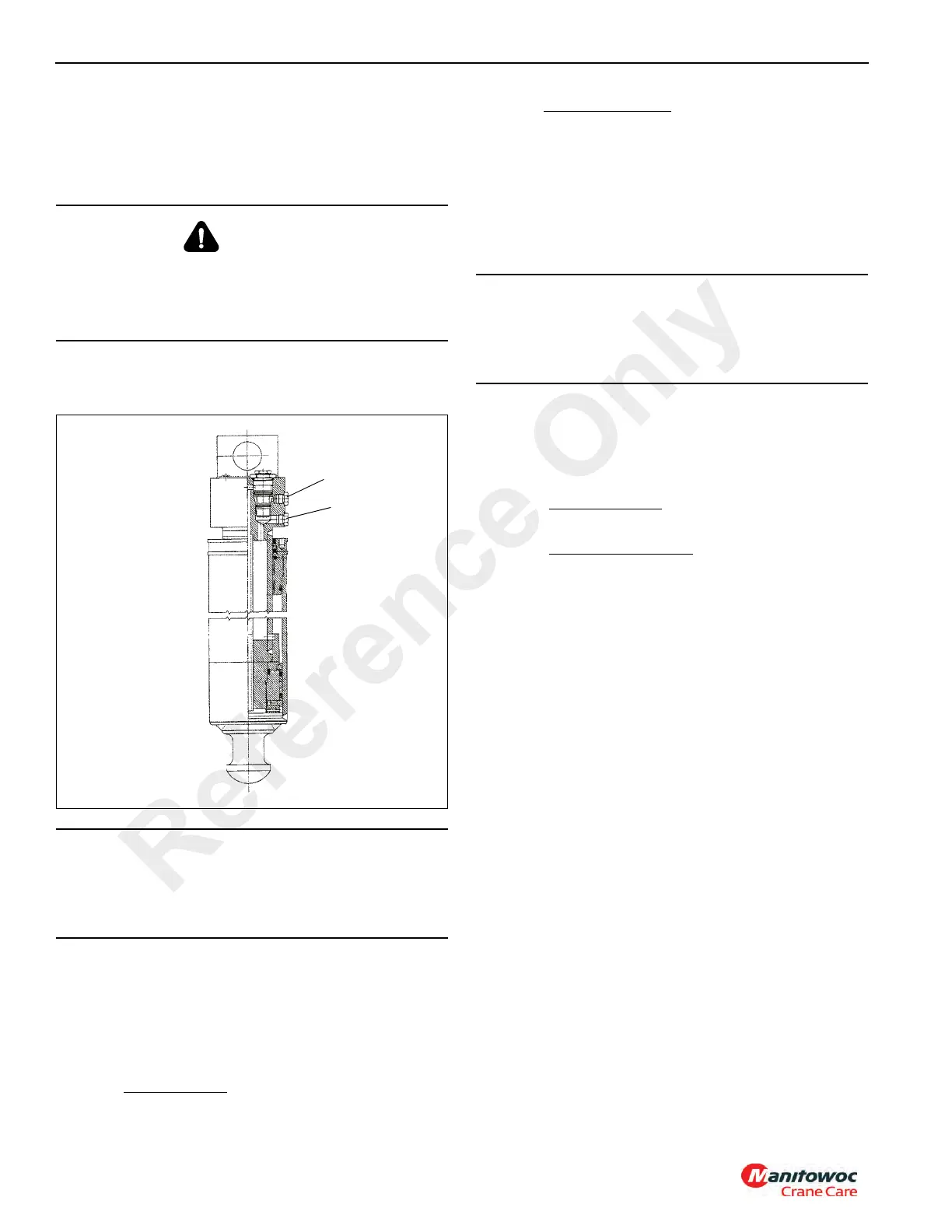

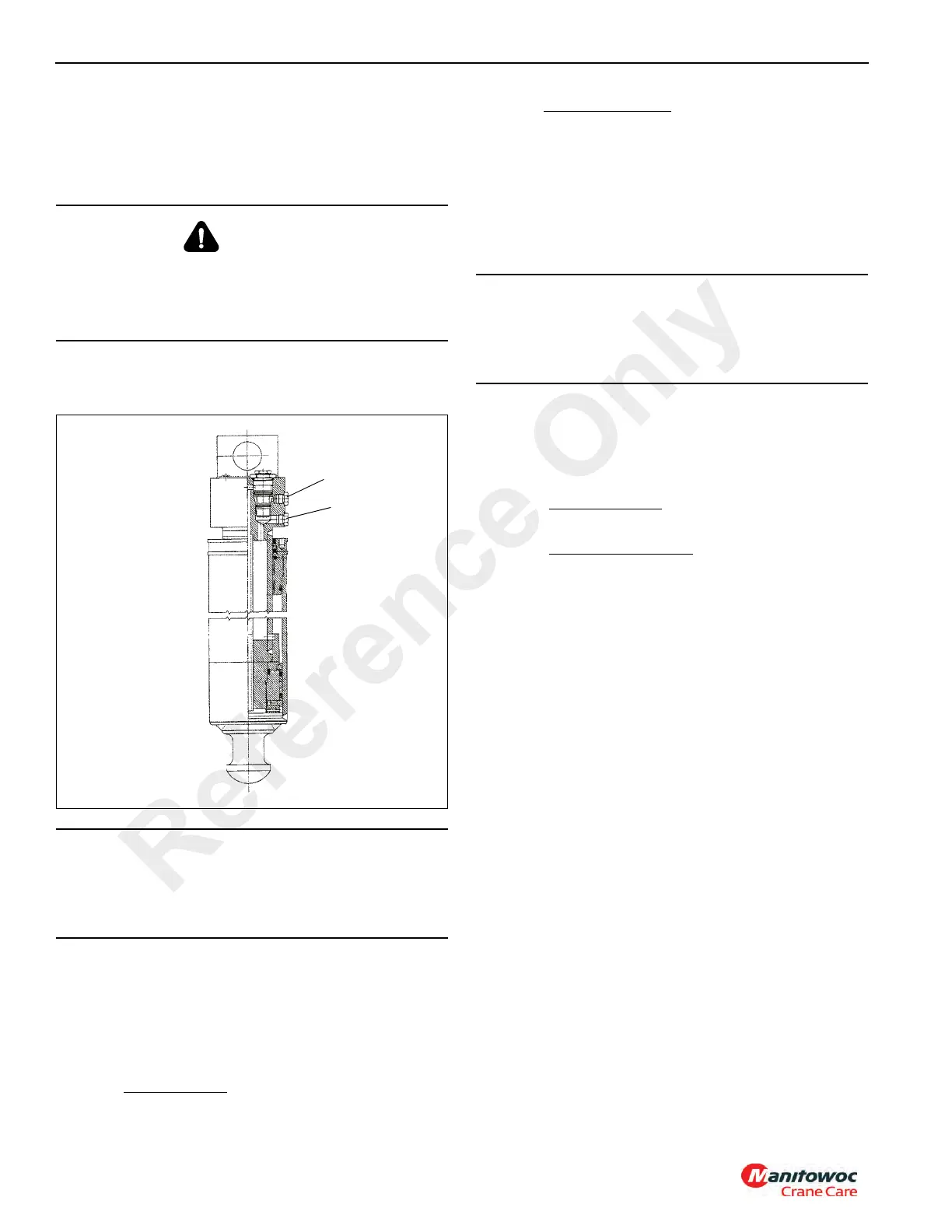

FIGURE 8-78

Piston Port

Rod Port

6432

CAUTION

When performing step number 2, remove hose to adapter

connection slowly. Trapped pressure may exit between

the outrigger cylinder and the work port pilot operated

check valves in the outrigger selector valve.

Reference Only

Loading...

Loading...