7-8

Published 01-29-2014, Control # 496-00

POWER TRAIN TMS800E SERVICE MANUAL

24. Connect the battery.

25. Position the start relay and the max speed relay on the

inside of the hood. Secure them with the bolts, washers,

lockwashers, and nuts.

26. Prime the fuel system and hydraulic pumps and start the

engine. Check all hoses for leaks. Shut down the engine

and check all fluid levels. Run the engine and

transmission to fill the transmission cooler and its lines

to and from the transmission. Stop the engine, check the

transmission fluid level again, and add SAE GRADE 50

synthetic gear lubricant to fill the transmission to the full

mark.

Engine Drive Belts

The proper operation of engine belt-driven components such

as the alternator, fan clutch, and water pump depend on the

proper condition and tension of the engine drive belts.

NOTE: Belt tension is maintained with an automatic belt

tension device.

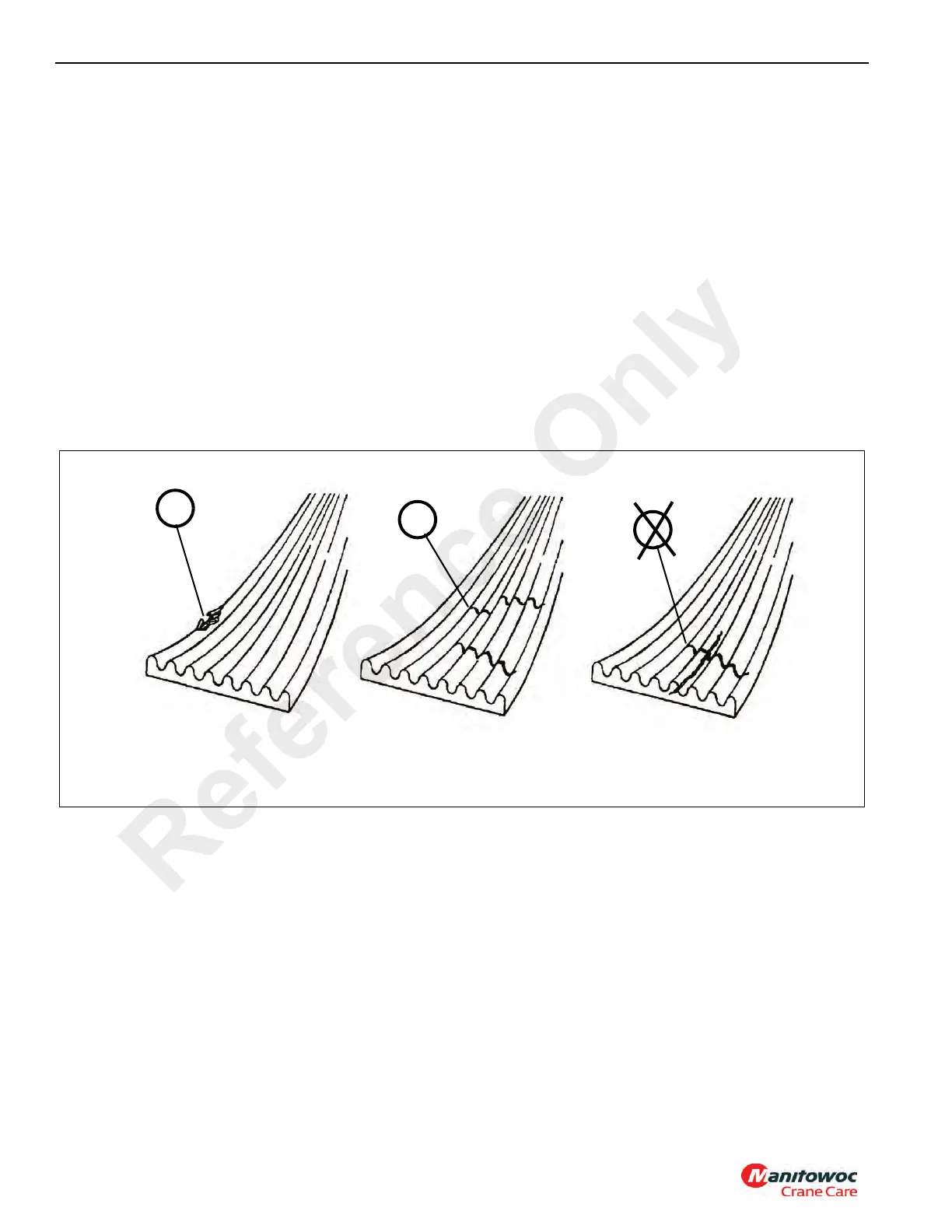

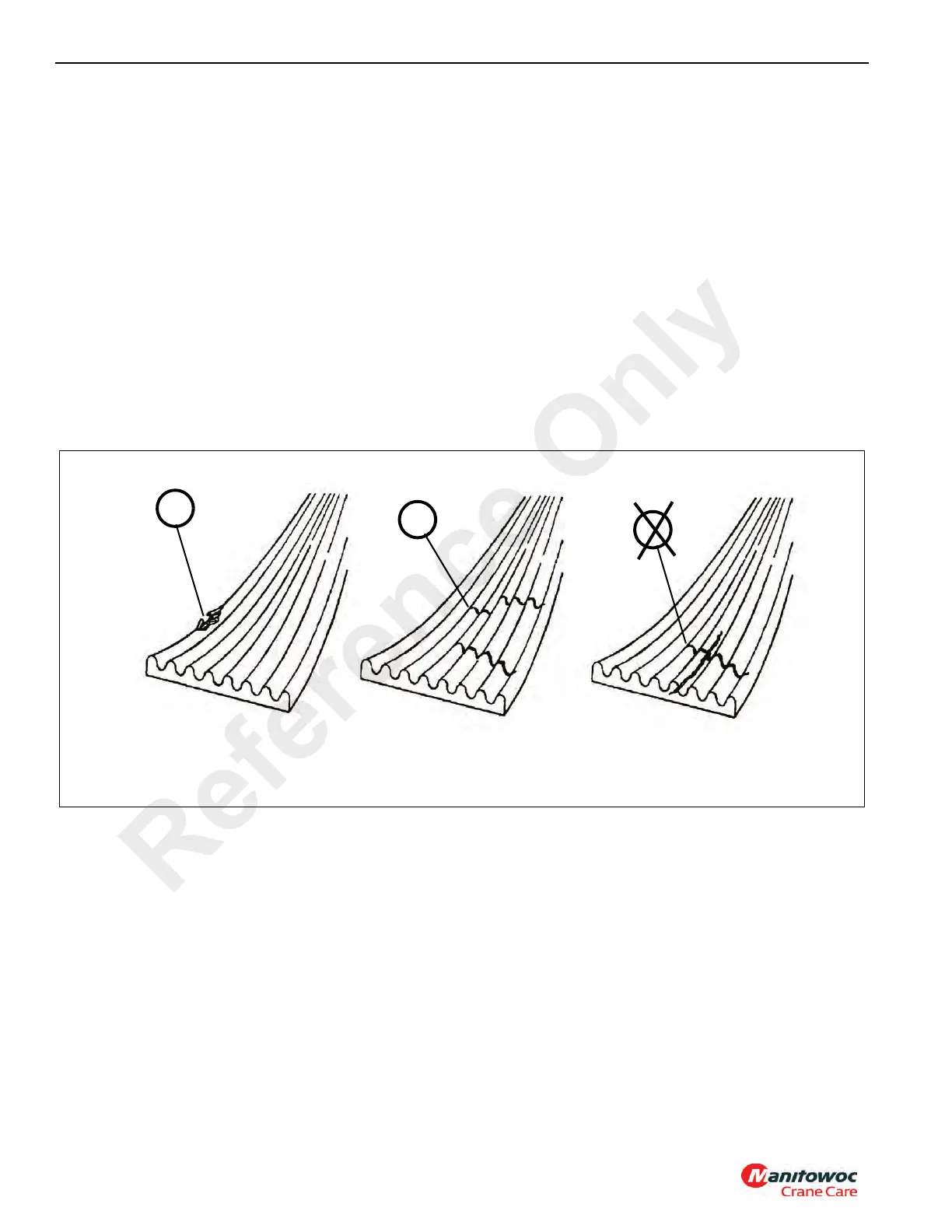

The engine drive belt should be inspected visually

(Figure 7-3) on a daily basis. The drive belt should be

inspected for cracks, frayed areas, and glazed or shiny

surfaces. A drive belt that is glazed or shiny indicates belt

slippage.

Engine drive belt damage can be caused by various factors

such as incorrect tension, incorrect belt size, misaligned

engine pulleys, incorrectly installed belts, or by oil, grease, or

hydraulic fluid on the belt.

Refer to the engine manufacturer’s manual for any special

tools or belt tension specifications.

OK

OK

OK

Missing Material

Traverse Cracks

Longitudinal Cracks Intersecting

with Transverse Cracks must be Replaced

FIGURE 7-3

Reference Only

Loading...

Loading...