9-9

TMS800E SERVICE MANUAL LUBRICATION

Published 01-29-2014, Control # 496-00

GROVE

20. Outrigger Beams

Lube Type - EP-MPG

Lube Interval - 50 hours or 1 week, whichever interval

occurs first

Lube Amount - Brush on bottom of outrigger beams.

Application - Brush on; 8 places

21. Jack Cylinder Support Tubes

Lube Type - EP-MPG

Lube Interval - 500 hours

Lube Amount - Brush on inside diameter of jack cylinder

support tubes and wear bands before installing jack

cylinders.

Application -Brush on; 5 places

22. Jack Cylinder Barrels

Lube Type - EP-MPG

Lube Interval - 50 hours or 1 week, whichever interval

occurs first

Lube Amount - Fully extend outriggers and brush

lubricant onto cylinder barrels.

Application - Brush on; 5 places

HYDRAULIC LUBRICATION

NOTE: Environmental and other conditions can

dramatically affect the condition of hydraulic oil and

filters. Therefore, specific intervals for servicing/

changing hydraulic oil, filters and hydraulic tank

breathers cannot be set. However, it is imperative

for the continued satisfactory performance of

Grove cranes that inspections be performed on the

basis of how and where each crane is used. Air

borne and ingested contaminants can significantly

reduce the life of oil and the condition of hydraulic

oil filters and tank breathers.

NOTE: Under normal operating conditions, it is

recommended that hydraulic oil, filters and

breathers be inspected and oils sampled at least

every 3 to 6 months and more frequently for severe

operating conditions. The inspections should be for

air borne and/or ingested particles and water that

deteriorate and contaminate the oil (for example,

oil appears “milky” or no longer has a transparent

clear to amber color). The return filter by-pass

indicator should be observed daily to determine if

the contaminants content may be high. If the

indicator reaches the red zone or indicates a by-

pass condition, the hydraulic oil must be sampled.

The hydraulic tank breather should also be

inspected to assure that it is not restricting air flow

into and out of the reservoir.

NOTE: To inspect hydraulic oil, fill a small glass container

with a sample of reservoir oil and another glass

container with fresh oil. Let the samples stand,

undisturbed, for one to two hours and then

compare the samples. If the reservoir oil is heavily

contaminated with water the sample will appear

“milky” with only a small layer of transparent oil on

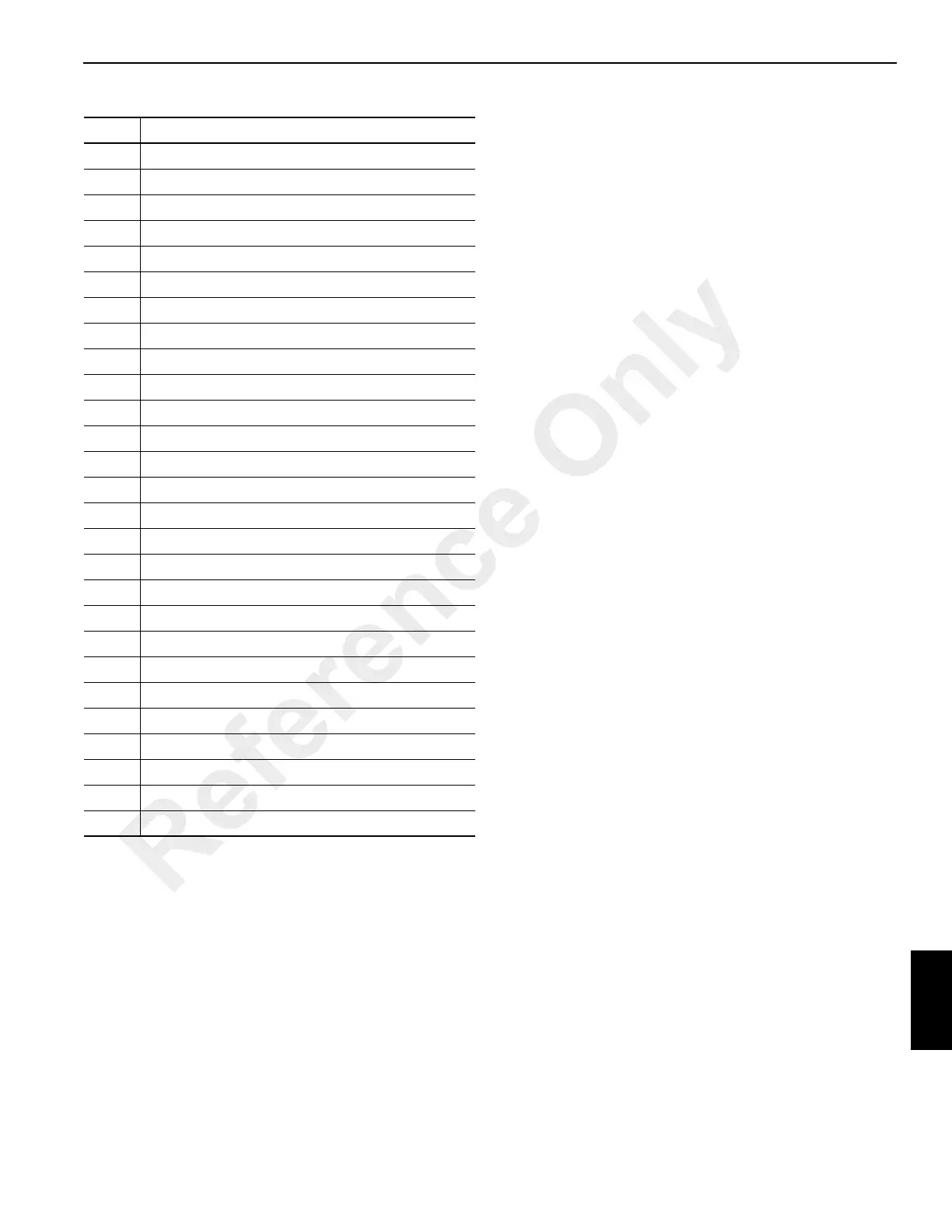

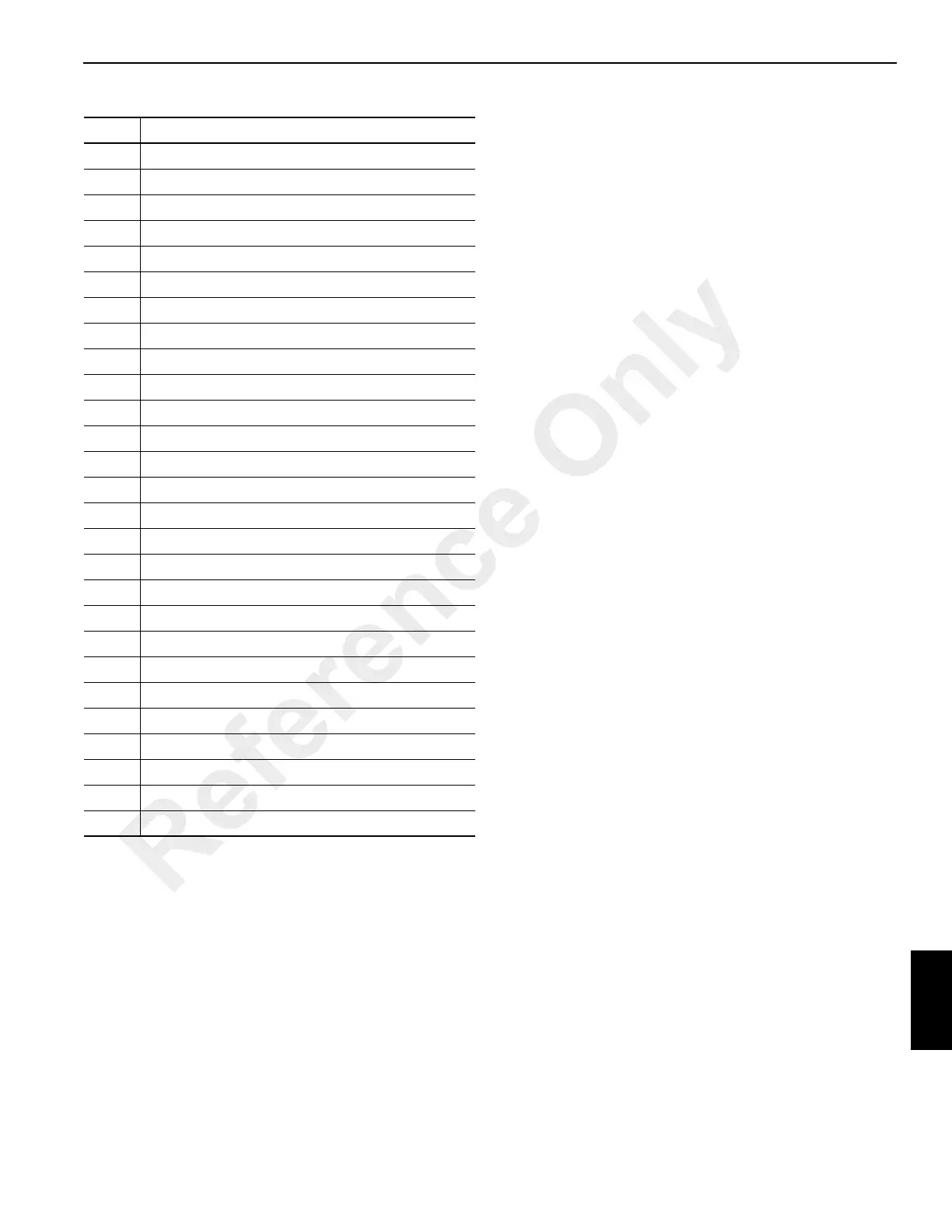

Item Description

1 Engine Crankcase

2 Engine Cooling System

3 Transmission

4 Pump Drive Shaft U-Joints and Spline

5PTO Clutch

6 Driveline

7 Power Steering Gearbox

8 Steering Relay Arms

9 Front Aluminum Wheel Pilots

10 Front Axle Hubs

11 Front Axle Tie Rod Ends

12 Front Axle King Pins

13 Front Axle Brake Slack Adjusters

14 Front Axle Brake Camshafts

15 Rear Aluminum Wheel Pilot

16 Front Rear Axle Differential

17 Rear Rear Axle Differential

18 Rear Axle Brake Slack Adjusters

19 Rear Axle Brake Camshafts

20 Outrigger Beams

21 Jack Cylinder Support Tubes

22 Jack Cylinder Barrels

23 Hydraulic Reservoir

24 Hydraulic Filter

25 Fuel Filter

26 Air Cleaner

27 Coolant Strainer (Superstructure Cab Heater)

Reference Only

Loading...

Loading...