HYDRAULIC SYSTEM TMS800E SERVICE MANUAL

2-24

Published 01-29-2014, Control # 496-00

PRESSURE SETTING PROCEDURES

The following procedures should be used to properly check,

adjust and set the hydraulic system pressures.

The following equipment is required for checking the

hydraulic pressure settings.

• Pressure Gauge

• Three dial gauge 0-345 bar (0-5000 psi)

• Diagnostic quick disconnect - Grove P/N 9999101806

and straight adapter fitting 7447040401

• ORFS reducers as required to attach work port hoses to

the gauge.

NOTE: When checking the directional control valve relief

settings, unless otherwise specified, start with the

engine at idle RPM and move the controller to its

fully stroked position. Then slowly accelerate the

engine to the specified RPM. Read gauge and

make adjustments to specified setting.

When checking the outrigger relief valve setting,

start with the engine at idle RPM and activate and

hold the extend or retract switch. Then slowly

accelerate the engine to the specified RPM. Read

gauge and make adjustment as required.

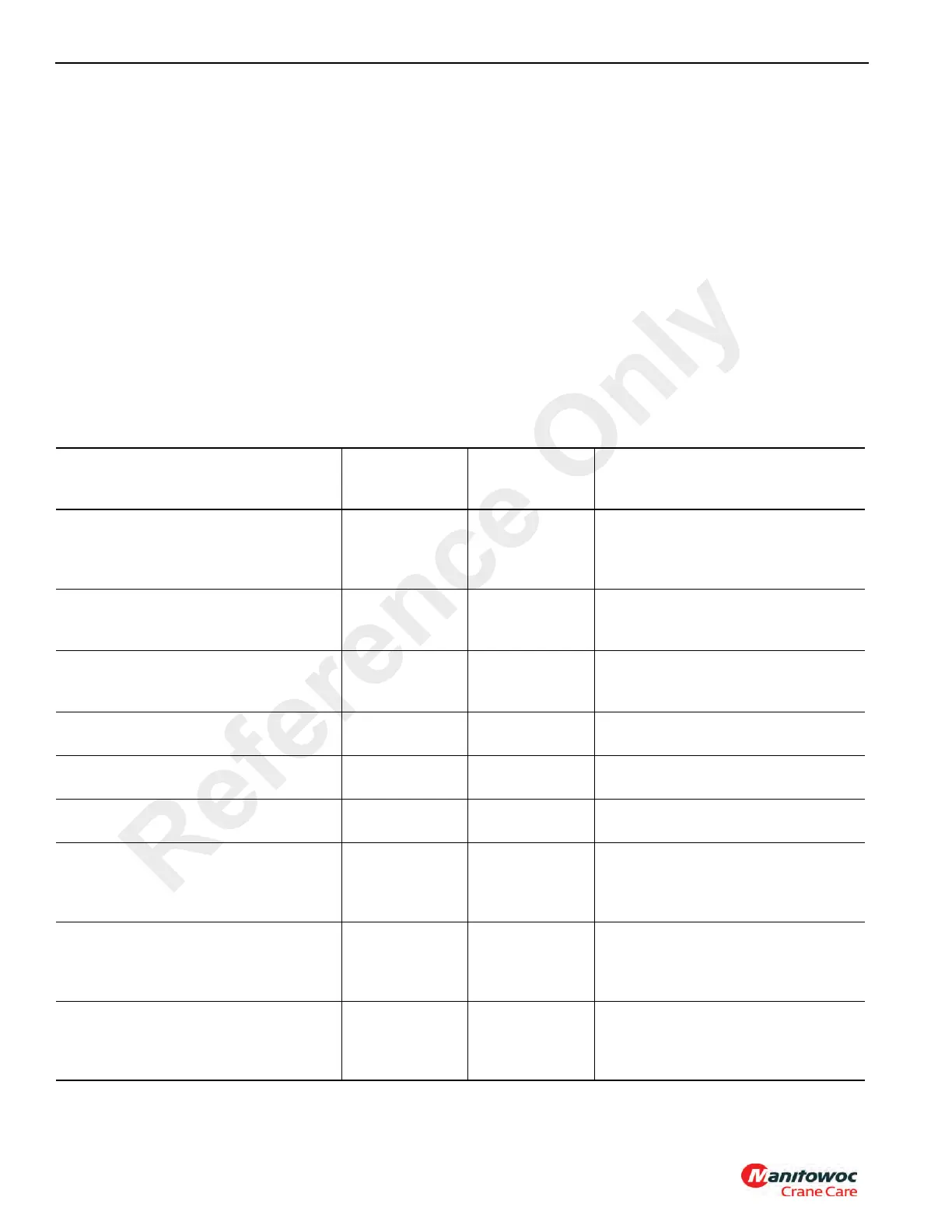

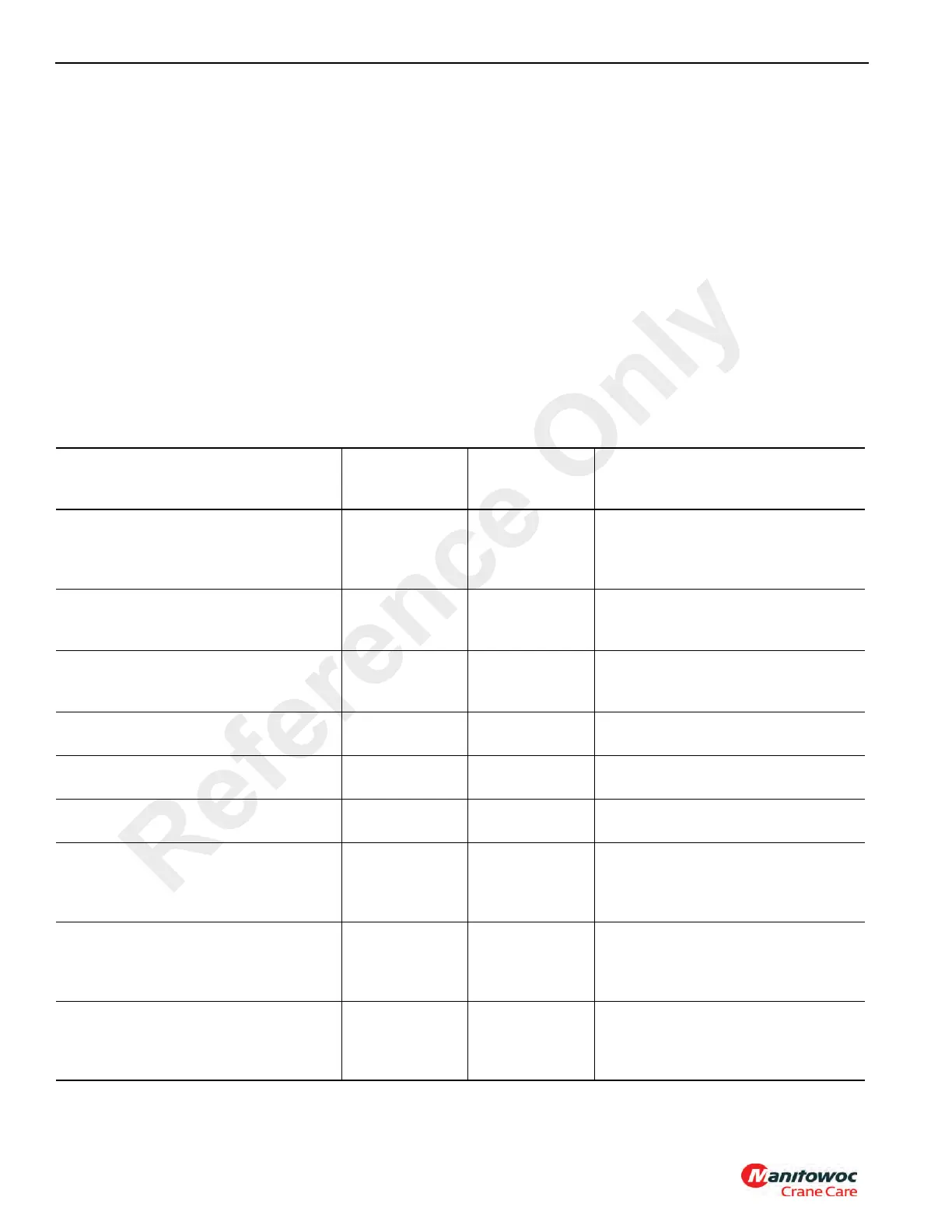

Table 2-2

Valve Pressure Setting Table

Reservoir Oil Temperature to be Approximately 49°C (120°F

Valve To Be Set

Pressure

Setting

bar (PSI)

Tolerance

bar (PSI)

Gauge Port (GPX) and Adjustment

Location

Hoist(s), and Lift Pressure Setting

276 (4000) ± 4 (50) GP2 Superstructure mounted

accessory manifold with swing

directional control valve (see

Figure 2-14)

Telescope Extend Pressure 179 (2600) ± 4 (50) GP5 Superstructure mounted main

directional control valve port relief

valve (see Figure 2-15)

Telescope Retract Pressure 239 (3460) ± 4 (50) GP5 Superstructure mounted main

directional control valve port relief

valve (see Figure 2-15)

Outrigger Extend/Retract and Swing Left/

Right Pressure Setting

214 (1500) ± 4 (50) GP7 Carrier mounted outrigger control

manifold (see Figure 2-18)

Air Conditioning Circuit Relief Valve

Pressure

103 (2000) ± 4 (50) GP Carrier mounted flow control

manifold (see Figure 2-17)

Steer Pressure Setting 150 (2175) ± 4 (50) GP8 Carrier mounted Priority Flow

Pump Relief (see Figure 2-19)

Swing Brake Supply Pressure Setting 18 - 20

(260 - 300)

See Range GP4 Superstructure mounted

accessory manifold with swing

directional control valve (see

Figure 2-14)

Pilot Supply Pressure Setting 28 - 31

(400 - 450)

See Range GP3 Superstructure mounted

accessory manifold with swing

directional control valve (see

Figure 2-14)

Counterweight Removal Extend/Retract

and Cab Tilt Relief Pressure Setting

172 (2500) ± 4 (50) GP2 Superstructure mounted

accessory manifold with swing

directional control valve (see

Figure 2-14)

Reference Only

Loading...

Loading...