7-30

Published 01-29-2014, Control # 496-00

POWER TRAIN TMS800E SERVICE MANUAL

PUMP/PTO CLUTCH ASSEMBLY (ISX

ENGINE)

The pump PTO clutch is used to engage/disengage pump 1

from the engine to aid in starting, especially in cold weather,

and to prevent the pumps from over-speeding while traveling

the crane. This clutch connects the PTO driveline to pump 1.

The clutch assembly is air operated and electrically

controlled.

PTO Clutch Lubrication

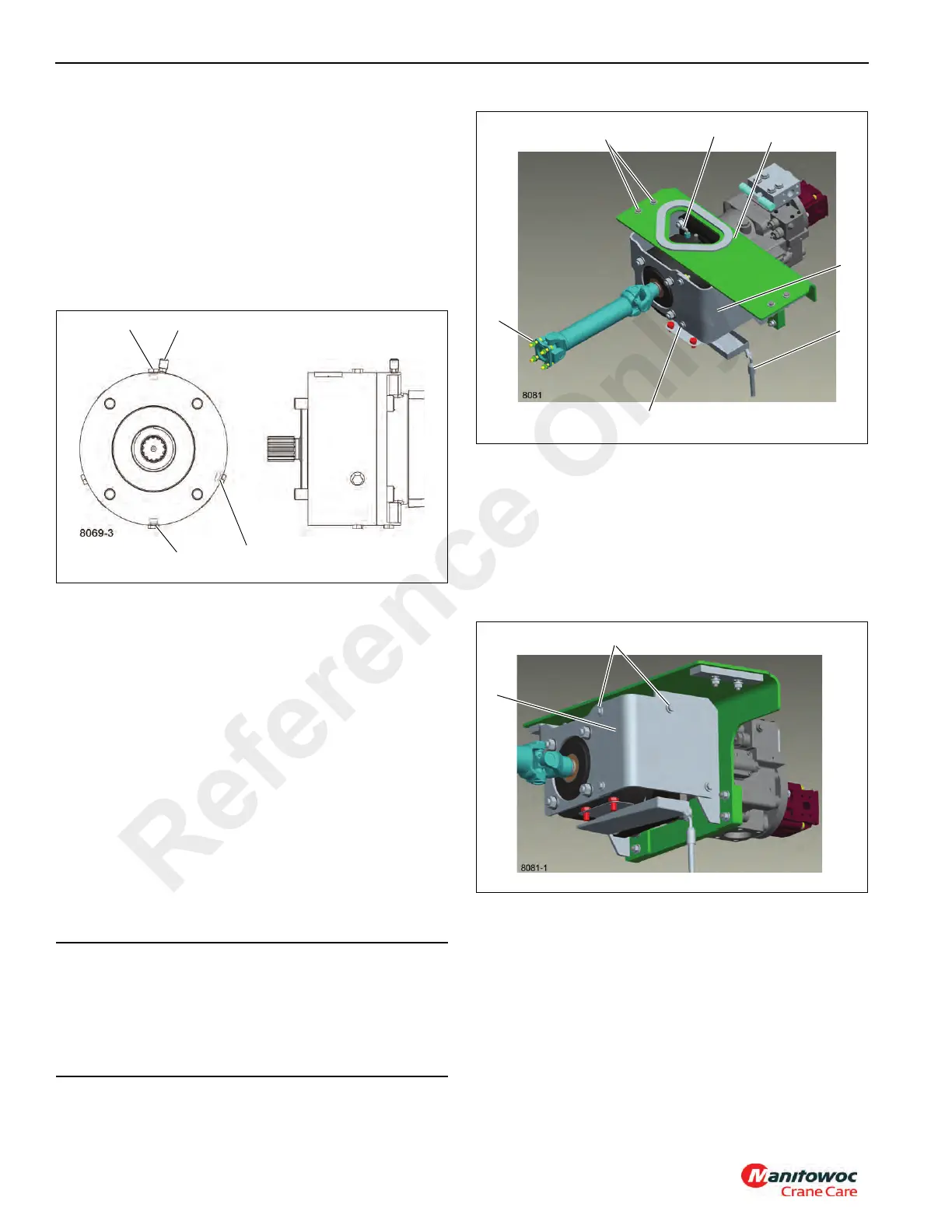

1. Remove access cover (5, Figure 7-17).

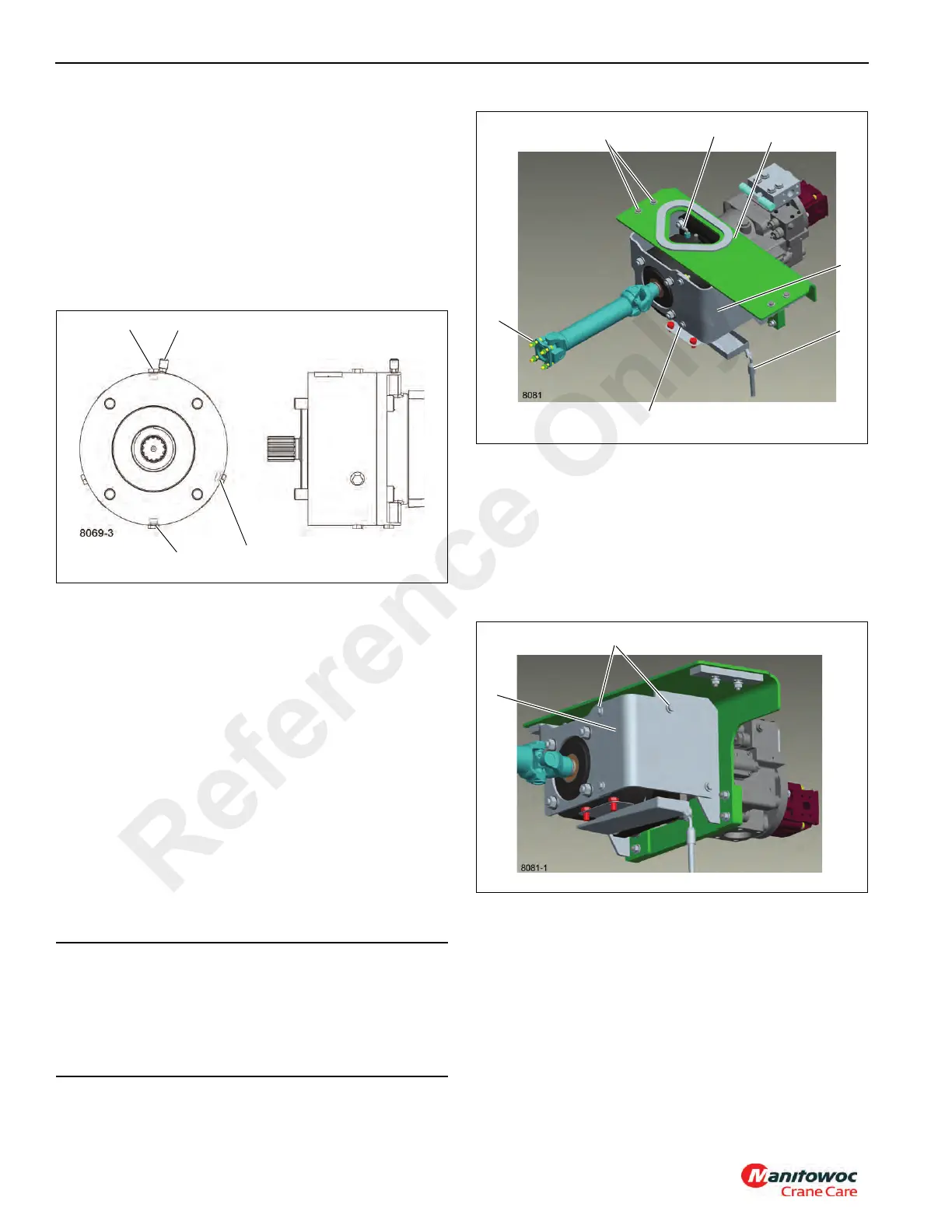

2. Open check plug (1, Figure 7-16) and check that oil is

even with bottom of threads.

3. If necessary, remove fill plug (2) and add hydraulic oil

until it is even with the bottom of the check plug threads.

4. Reinstall access cover (5, Figure 7-17) and secure with

hardware (7). Refer to Fasteners and Torque Values,

page 1-13.

When changing oil, place suitable container under drain pan

hose (6, Figure 7-17) before removing drain plug (4,

Figure 7-16). Remove and clean breather (3) and inspect

and clean magnetic drain plug (4) for contamination or

particles before reinstalling. For more information, refer to

Lubrication, page 9-1.

Pump/PTO Clutch Replacement

Removal

1. Depressurize the hydraulic system.

2. Depressurize the air system and disconnect the clutch

air line (1, Figure 7-17) from the clutch.

3. Remove the cap screws, nuts and washers (2)

connecting the PTO driveline to the engine. Remove the

driveline.

4. Remove the access cover (1, Figure 7-18) by removing

the four cap screws and washers (2) and two “double-

nut” plates.

5. Tag, disconnect and plug or cap the hydraulic hoses and

ports on the clutch.

6. Tag, disconnect and plug or cap the hydraulic hoses and

ports on the pumps.

7. Tag and disconnect the electrical connectors to the

pumps.

CAUTION

Damage could occur!

Absolute cleanliness is essential when working on the

hydraulic pumps. Always work in a clean area. The

presence of dirt and foreign materials in the system can

result in serious damage or inadequate operation.

Reference Only

Loading...

Loading...